Cold welding for metal: pros and cons

A modern adhesive with a high level of strength is required for many jobs in various industries. This material is cold welding. The products have found their application in the field of repairing vehicles and plumbing fixtures, eliminating various defects on metal surfaces and restoring threads.

Peculiarities

The composition can be used in any areas where conventional welding for metal is effective, however, a number of objective reasons prevent the latter from working. This method of joining metal surfaces consists in combining the elements using the plasticity of the welding mixture, which penetrates into the material.

A feature of cold welding is also the fact that there is no need to purchase specialized expensive equipment to ensure productive work. This method can be attributed to pressure welding, however, the adhesion is obtained due to deep plastic deformation, which destroys the oxide layer of the material, which makes the distance between the elements similar to the parameters of the crystal lattice. It is the increase in the energy level of substances that favors the creation of a strong chemical bond.

The properties of this material make it possible to work with surfaces and structures made of non-ferrous and ferrous metals. The main feature of this bonding method is the fact that cold welding is ideal for repairing metal products that are sensitive to heat, and provides a reliable connection between various metals.

The method has several advantages.

- The products are available to consumers, sold in many supermarkets.

- In most cases, it is possible to connect the elements without first dismantling them.

- The work does not take much time.

- The surfaces to be glued do not deform as they are not exposed to high temperatures.

- The weld seam meets the requirements of aesthetic appeal.

- Often this method is the only way to connect parts. This applies to the welding of elements made of copper and aluminum, as well as containers that contain explosive substances.

- The technology eliminates waste generation.

- It is not necessary to exert maximum effort to carry out the process of joining parts.

- The material is absolutely harmless.

- No special skills or special tools are required for work.

- There are heat-resistant varieties of the composition with which you can work at temperatures above +1000 C.

The disadvantages of the material include several features.

- The strength of the weld is still lower in comparison with conventional welding, so the products are not always suitable for industrial applications.

- Cold welding is not marketed as a material for repairing large defects.

- The surfaces to be joined need to be thoroughly cleaned before applying the compound. Otherwise, the quality of adhesion decreases sharply.

Views

Based on the location of the joint and the type of working surfaces, several types of cold welding can be distinguished.

- Point - recommended for tires and kitchen utensils made of aluminum and copper, for attaching nozzles to aluminum wires, thereby increasing the quality of the connection of electrical contacts;

- Suture - designed for the production of cases of various devices and equipment, as well as volumetric sealed containers;

- Butt - used for making rings and connecting wires;

- Tavrovaya - used for gluing brass studs, electric locomotive busbars;

- Shear welding - designed for pipes providing water supply, including heating systems, as well as for transmission lines on the railway.

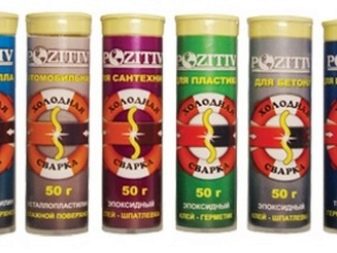

Depending on the adhesive composition and its density, welding is classified as follows:

- Plastic-like, resembling a bar with one or two layers (the technology of using such a material requires preliminary mixing and softening of the product);

- Liquid, consisting of an adhesive and a hardener that must be mixed before application (which is why it is called two-component).

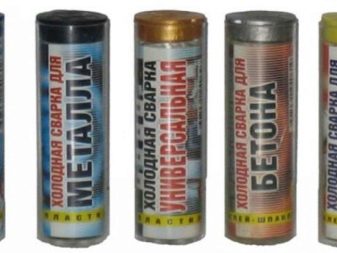

There are several types of cold welding with respect to the target orientation.

- Water resistant composition for work in water.

- A vehicle repair product containing metal filler. This welding is produced specifically for work with automotive parts.

- A product designed for working with metals, which has a certain filler in its composition, thanks to which almost all types of surfaces are connected to each other.

- Universal welding. It provides a reliable connection of different materials (wood, different polymers, etc.). This product is the most demanded on the market.

- High temperature cold welding. It can be used at temperatures from +1500 to -60 C.

Specifications

Cold welding is an epoxy resin-based plastic adhesive. The two-component composition can be stored for a long time without losing its basic properties. One-component products require quick application, as they quickly lose their bonding qualities.

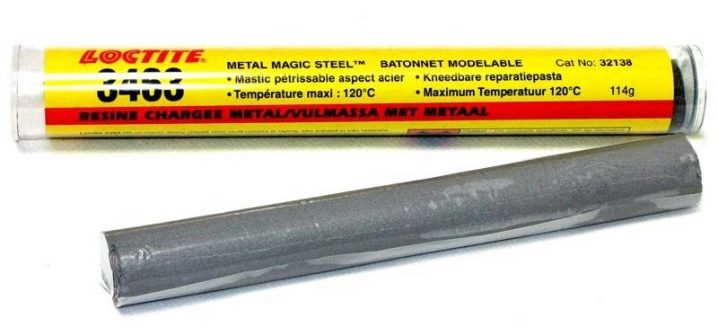

Most often, the product is produced in the form of a two-layer cylinder. Its shell is a hardener with resin and metal dust inside. This additive provides a strong bond.

In addition to the main components, welding also includes other additives, such as sulfur. Additives provide unique quality characteristics of the composition. Manufacturers, as a rule, do not disclose the entire list of substances used.

The main components that are present in most cold metal welds are the following:

- epoxy resin - the main element (provides bonding of materials to each other);

- filler, which is a metal dust (responsible for the strength of the entire bond, making the seam heat-resistant);

- various additives, the composition of which is formed by the manufacturer depending on the type of welding.

The temperature characteristics of cold welding also depend on the composition of the product. Usually, the instruction for the product contains information about the parameters, subject to which the connection will be reliable and durable. For most of the compositions, the maximum is an indicator equal to +260 C.

Manufacturers

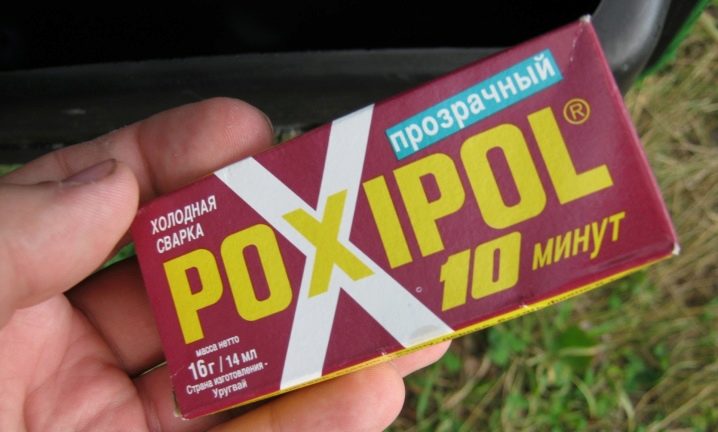

In the domestic market, the most popular manufacturers are foreign companies, since Russian products are of lower quality, as evidenced by numerous consumer reviews. Domestic products are represented by trade marks Almaz or Polymet, Henkel... The leaders among foreign rosters are Hi-Gear, Abro, Poxipol.

Abro steel - American two-component universal welding. The material withstands the effects of various aggressive substances and perfectly retains its properties up to a temperature of +260 C.

Hi-Gear "Fast Steel" made for work with metal, plastic and stone. The products provide a strong connection, resistant to mechanical and chemical stress.

Henkel "SuperEpoxy Moment" widely used for joining metal alloys and other materials.The composition retains its properties up to a temperature of +140 C.

Uruguayan Adefal Trading S. A. Poxipol - universal two-component cold welding. The maximum temperature for such products is +120 C.

Germanic Wurth Liuguid Metal Fe 1 produced for work with ceramic and metal parts and structures. The material is non-combustible and does not contain solvents. The composition of the welding ensures its resistance to aggressive substances. The maximum temperature for such products is +120 C.

Cold welding for batteries and water pipes Mastix better than all other compositions it copes with the task of sealing cracks and other defects on such structures. The temperature in the pipelines does not exceed the permissible component of +120 C, so the products can be used at home. Such welding allows for the creation of lost parts and new parts.

Metal silicate products Kerry "Thermo" has a high viscosity. It has proven itself to work well with heat-resistant alloys made of steel, cast iron and titanium. The composition is resistant to mechanical stress, therefore it is recommended for the repair of automotive parts. The product can withstand temperature drops from +900 to -60 C.

Advice

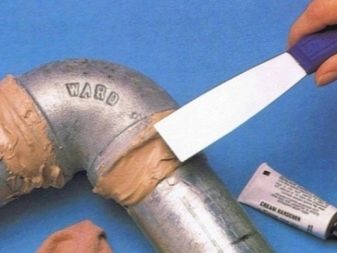

In order to properly apply the composition, it is necessary to perform a number of preparatory procedures. First of all, you need to remove dust, greasy deposits, oil stains and other contaminants from the surface. This also applies to rust, it is carefully cleaned off to provide access to the bonded surfaces. Only after the coating is suitable for work should you start welding.

Two-component formulations are removed from the package and mixed thoroughly. Liquid and solid compositions must come to a state of plasticity, due to which they can be given a different shape. Work is carried out only if safety measures are observed - it is necessary to exclude the risk of products getting on the skin.

As soon as the composition acquires an acceptable consistency, it must immediately be used for its intended purpose, since the material dries quickly.

It is recommended to control the thickness of the applied material. The first layer should not exceed 6 mm. If necessary, a second layer of cold welding is applied, but only after the previous one has completely dried out. It will be possible to operate the structure for its intended purpose when the composition is completely solidified.

Many buyers are wondering which cold weld is best. It is difficult to answer such a question, since the technical characteristics of the composition are selected individually, taking into account a number of important nuances that relate to the type of metal surfaces, operating conditions and many other fundamentally significant factors.

The only recommendation is the desire to give preference to well-known brands, whose products have positive reviews. However, in this case, the cost of production will be quite high.

There are several points to look out for when purchasing a cold weld.

- The presence of additives in the composition and their variety. The filler must correspond to the type of metal that will be glued using the composition, or have a strength not lower than that of this material.

- Indicators of the minimum and maximum temperature in the range of which the composition retains its technical performance. High temperature formulations are much stronger.

- The solidification time of the welding is often of fundamental importance. Therefore, it would be more correct to purchase two types of product: for quick gluing and a standard type. Although in most cases, the latter type provides a more reliable and high-quality connection.

Undoubtedly, the products have some disadvantages, but provided that the material is correctly selected, you can easily cope with the problems that have arisen, even if the user's professional experience is minimal.

See the next video for how cold welding works.

The comment was sent successfully.