How to apply Mastix cold welding?

Cold welding Mastix allows you to join parts without deforming them. This procedure can be compared to gluing. It is quite easy to use such a tool: you just need to understand certain nuances, features of specific types of material.

Peculiarities

Various cold welding materials are available to consumers today. However, not all of these formulations are suitable for use with significant temperature differences. For this reason, not every product is suitable for industrial applications.

Welding Mastix is a material that significantly surpasses many analogues in terms of performance. This composition can be used at both low and very high temperatures. This material is of higher quality than conventional glue. With this kind of cold welding, you can join parts made of different materials.

This composition can be used both for new products that have not been used before, and for broken parts. High quality Mastix products even allow new parts or lost parts to be formed. With this material, you can fill cracks, various holes.

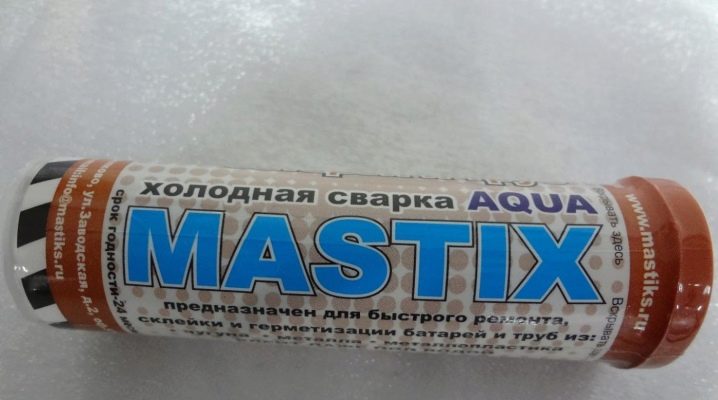

Cold welding Mastix looks like a rod. This material combines different components: the first of them is the outer shell, and the second is located inside.

Before starting work, you need to thoroughly mix the material, in the end you should get a soft mixture. She will be in this state for several minutes. Then the composition will begin to solidify, and after a while it will completely solidify.

Advantages and disadvantages

Such formulations have many advantages.

Among the most significant advantages, several qualities can be distinguished.

- The two-piece rod is very convenient to use.

- The cost of Mastix materials is quite reasonable, such products are available in different stores.

- This mixture can also be used by novice masters. To use it, you do not need any special knowledge and skills.

- The manufacturer offers several varieties of such products. Consumers can purchase both universal formulations and welding for any specific materials.

- This material provides high bond strength.

Cold welding Mastix has not only positive, but also negative qualities, however, many buyers in the reviews call them insignificant.

- After stirring the material, you should make sure that there are no lumps in it. Otherwise, later it may become necessary to redo the work.

- Such a composition dries for a rather long time.

Scope of use

Cold welding Mastix is suitable for a wide variety of applications. Consideration should be given to the external conditions and the type of composition. Most often, cold welding is used as a regular glue in order to fasten any elements to each other.

With this material, you can restore machine parts, plugging up various holes and so on. Since this composition is plastic, it is very well suited for sealing cracks. Remember that the material must dry completely: it is not recommended to use the processed product before.

The hardened mixture will not be resistant to strong mechanical stress. However, such material is quite resistant to vibrations, so it can be used to repair moving mechanisms.

Mastix welding is successfully used for the restoration of plumbing fixtures (batteries, pipes). This material is suitable for the repair of furniture, aquariums, various household items.

Such mixtures consist of the following components:

- amine resin;

- metal fillers;

- epoxy resin;

- fillers of mineral origin.

Varieties

Various types of Mastix cold welding are available to consumers.

- For metal surfaces. This material contains a filler made of metal to ensure maximum joint efficiency. Before using such a composition, it is not necessary to make the surfaces completely dry: it goes well with the liquid. For this reason, this material is often chosen for plumbing. Surfaces also do not have to be cleaned of dirt.

- Universal. This type of welding is suitable for a variety of surfaces. It is effective at various temperatures. Since this material can be used in a wide variety of applications, it is very popular: consumers leave many positive reviews about such cold welding.

- Heat resistant (sold in red packaging). This Mastix cold welding is resistant even to very high temperatures (up to 250 degrees).

- For plumbing. This material is suitable for metal elements, for porcelain.

- "Fast Steel". This material contains steel fillers. With the help of such welding, it is possible to restore the lost elements.

- For aluminum products. This composition contains an aluminum filler.

How to apply?

If you are going to operate cold welding Mastix, you need to carefully read the instructions for use. This way you can't go wrong with the sequence of actions.

There are Mastix materials that are resistant to dirt, however, before starting work, it is still better to thoroughly clean the parts anyway. If you are going to use universal welding, be sure to remove the oil layer from the surface.

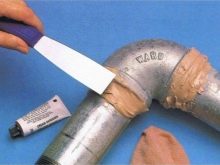

Cut a piece from the cold weld bar and mix thoroughly. The result should be an absolutely homogeneous pasty mass. It will need to be applied to the surface. After that, connect the products, fix them and wait a little more than half an hour. They will finally connect in two to three hours.

The shelf life of Mastix cold welding is 2 years. This material does not have to be disposed of in any special way. If applied correctly, it will be absolutely safe for human health.

When using cold welding, you need to be very careful: the material should not be on the mucous membranes. When using such a composition, it is recommended to use rubber gloves. This will help protect your hands.

What is cold welding and what it is used for, see the video below.

The comment was sent successfully.