All about OSB boards for interior decoration

Sheet materials are in great demand not only during construction, but also for interior decoration. Today, one of the representatives of these products are OSB boards, which arouse consumer interest for a number of objective reasons. There are several varieties of this material on the market, so first you should familiarize yourself with its characteristics and installation methods.

Can I use it?

Oriented strand board is offered in the form of panels, the main raw material for its production is pressed shavings of various types of wood.

The main advantage of the material is its high strength and density, since it consists of several layers. There is a sheet inside the product, with elements located across, and a longitudinal version is provided in the upper and lower layers.

Pressing takes place under the influence of pressure and high temperature, waterproof resins and paraffin are added to the composition. The latter ingredients are suspicious of many, as they are believed to be harmful.

The question of whether it is possible to use the slabs as an interior decoration can be answered as follows. OSB is offered in different versions, the marking indicates the amount of synthetic substances that can be released under the influence of temperature. Therefore, first you need to consider which class the panel belongs to. Some of their types are not dangerous for the environment and human life, so they can be installed indoors as decoration.

However, OSB is also in demand in external work, therefore it is often used outside the home. It is possible to sheathe ceilings and walls using plates that have certain markings, which can be found in more detail below. It is worth noting that OSB is also suitable for the construction of partitions to zone the space. The sheets are strong, but at the same time light enough for transportation and installation. Plates can be installed both on a wooden frame and using a metal profile.

Species overview

There is a wide range of slabs on the market that have their own markings and are in demand for the arrangement of various premises. We bring to your attention the main characteristics of different classes of this material.

The most "delicate" slabs are OSB 1, which can be used as cladding only in dry rooms, where there is not even the slightest hint of moisture.

Resin is used as chip bonding agent... Such material is offered at an affordable price, but it should be borne in mind that it will not be able to withstand a significant load, therefore, such qualities affect its low popularity. In addition, slabs with this marking are not so easy to find in hardware stores, so the search can take some time.

The next class of panels is designated OSB 2. Resin also acts as a binder. This material has a high resistance to stress, which is why it is often used as a blockboard. The scope of application of the plates is the interiors of a living room with a low humidity index. You can find a material with a protective coating on the market, so it can be used in the bathroom too.

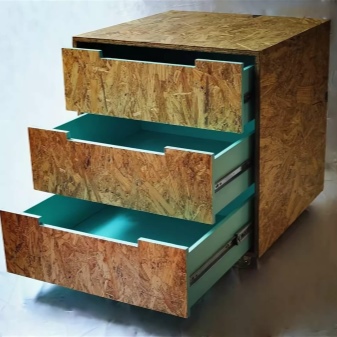

Often, such plates are used in furniture manufacturing enterprises, and the panels are also suitable for indoor cladding.The product is offered in different sizes, which are considered optimal in construction. Thin slabs act as wall coverings, while 15 mm thick panels are used for the manufacture of furniture and interior items.

Plates marked OSB 3 are produced with the addition of two types of resin. An organic adhesive is used for the middle layer, which mixes with the shavings, and the outer sides include organic resins. The material has an excellent indicator of endurance in a humid room, moreover, it copes with stress. Panels are often used not only inside, but also outside for cladding facades. The product is suitable for the manufacture of load-bearing structures due to its high strength.

There are a lot of areas of application for this slab; it can serve as a floor covering, partitions and interior wall decoration. The 22mm material is often used for roof sheathing and is available in large sizes and is durable.

One of the most durable and strong options are OSB 4 plates. They easily cope with high humidity and heavy loads. It should be noted that this type of material is considered universal. The only drawback of the panels is their high cost, but this is insignificant with all its excellent performance characteristics. Such plates can be used both indoors and outdoors, they are not afraid of adverse conditions. The use of OSB panels is quite extensive, so the material is in demand.

How to choose?

OSB is often chosen to carry out quick repairs and equip a room for living, without having to spend huge sums on building materials. The quality of paneling is at a high level, with which one cannot but agree... In addition, they can be used to make architectural structures and create built-in furniture. This product has ample opportunities, so it is quite popular. But first you need to figure out what to look for when choosing panels, how to choose the right material.

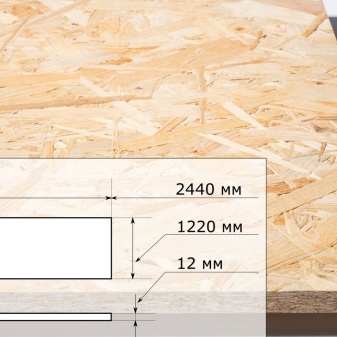

Today, the market offers sheets from foreign and domestic manufacturers. A great advantage is the wide range of sheet material parameters. The dimensions of the panels are not standard, therefore they differ depending on the capabilities of the manufacturer and and on the needs of the consumer. For example, American manufacturers produce OSB with a size of 2440x1220 mm, which is typical. This material is best suited as a floor covering.

The size must be selected depending on the purpose of the application of the material. Thickness is also an important characteristic, as the boards are offered in the range of 6-40 mm.

When it comes to wall cladding, 6-9 mm panels are the best choice, but when it is necessary to make partitions, it is better to choose a material with a thickness of 12 mm. As for the harmfulness, as mentioned above, you need to pay attention to the amount of binder. It is necessary to decorate the room inside with a safe and durable material that will last a long time.

Installation features

After purchasing OSB plates, you need to understand the installation rules if you decide to do the work yourself, without outside help. Since the panels are such a material that is easy to process, they can simply be cut to suit the parameters you need. First you need to make measurements, many stores can offer a service of cutting building materials. But if you can do it yourself, then you need a hand or table saw, the plates are easy to cut with such a tool.

Screws or special nails should be used as elements connecting the panels.

As for the frequency of their placement, 30 cm in the middle is considered standard, and 15 cm around the perimeter of the sheet. Some craftsmen fix the sheets with glue, but this solution is not suitable for everyone. When installing, it should be borne in mind that the material can expand over time, so it is important to leave gaps between the sheets, which are filled with elastic adhesive designed for working with wood.

Floor

The first step is to decide where the flooring will be installed, what kind of room and its conditions. This will be needed in order to choose the optimal thickness and size of the sheets. If we are talking about arranging an apartment, you can safely take plates of the OSB 2 class, OSB 3 is more suitable for laying on the first floors, and OSB 4 for the basement. To ensure maximum fit, it is recommended to stock up on grooved products.

Many people ask the question, is it really possible to use such sheets for the floor?

In this case, laying on a crate, logs or a concrete base is allowed. Indoor slab is often used in conjunction with linoleum, decorative slab and carpet.

As for the sealing of seams, the main difficulty lies precisely in this, since gaps are formed between the sheets. To get rid of this trouble, craftsmen use elastic plaster, thanks to which it is possible to restore the structure of the cladding even when the material has changed in size.

Walls

This process is practically no different from the previous one. The first step is to build a frame made of wooden beams or a metal profile. If you need a scheme for a lathing device, first make a markup, this will always be the first step. Of course, you should make sure that the walls, like the floor, have a flat surface, if this is not the case, it is necessary to eliminate defects. Draw a line along the wall, then fasten the profile with dowels or self-tapping screws.

After that, vertical profiles are installed in the guides and fixed with metal hangers, and horizontal ones with self-tapping screws.

To give rigidity to the crate, the racks must be reinforced with profiles across. If the ceiling heights are standard, two elements per span will suffice.

It is recommended to carry out waterproofing to prevent deformation of OSB panels, which can change their properties under the influence of moisture. This must be done in the case of facing a balcony, bathroom, kitchen, etc.

Ceiling

Attaching OSB to the ceiling is not as difficult as it might seem at first glance. The best installation option would be a mount without a frame. For city apartments, this installation method is best suited. However, here it is also important to make sure that there are no dips and bulges on the ceiling, otherwise such defects will become more noticeable after finishing. In country houses, the ceiling is often made of wood, therefore, after checking the surface with a level, it is necessary to cut off all the protrusions and repair any cracks. Experts recommend sheathing the area with foil insulation, after which you can start marking the area for the dimensions of the sheets.

Always fix the first slab in the center, or start from one of the corners. The nails are driven in crosswise with a distance of 30 cm. If you notice a skew and the joints do not match, you will need to use a jigsaw to cut off part of the sheet.

To install OSB panels on a concrete ceiling, you will need to use a puncher to make holes. After that, it is necessary to perforate the plates themselves so that their holes coincide with those that are already in the ceiling. Use dowel nails for hemming. Any room sheathed with OSB panels will look neat and beautiful. It should be noted that after installing the sheets on the floor, walls or ceiling, it will be necessary to carry out finishing work to make the surface presentable.

How to make a ceiling from OSB slabs, see the video.

The comment was sent successfully.