WPC facade panels: types, characteristics and installation

WPC cladding facade panels are a modern take on the exterior design of buildings. They are designed not only to protect external walls from climatic and weather influences. They are durable, aesthetic in appearance, economical and easy to install.

Advantages and disadvantages

A building material such as WPC is a combination of wood-based flour, dyes, and polymer additives that are connecting links between different components. Thanks to this combination, the product has the useful properties of plastic and wood, it retains its saturated color for a long time, is durable and long-lasting, and is immune to ultraviolet light.

The main advantages of composite panels are due to the following several indicators:

- high strength, no deformation - chips, cracks, dents, which is typical for metal and wood in its pure form;

- fire resistance when properly assembled;

- increased heat and sound insulation and the possibility of ventilation;

- resistance to fading, exposure to sunlight;

- the material is not susceptible to mold, fungus, bacteria, and is immune to rust;

- siding does not shrink, is waterproof;

- composite panels do not emit toxic compounds;

- installation is carried out quickly and easily using special fasteners;

- the characteristics of the product are not affected by critical low and high temperatures;

- preparation of the surface of the walls before installation is not required;

- the material does not require additional decorative design;

- in the presence of a large range of products.

In addition, WPC boards have a long service life - about 25 years, during which they continue to retain their original color and brightness.

Separately, it is worth noting the ease of maintenance. - the panels can be washed with ordinary water with the addition of detergents, however, without the use of abrasive substances and coarse, hard brushes and sponges.

Of the minuses of the building material, its high cost is distinguished, compared with similar siding made of metal and polyvinyl chloride, in addition, dark-colored slabs in the first year of operation still lose some color saturation. Despite the fact that WPC boards are subject to thermal expansion under the influence of external conditions, this is not considered a disadvantage. This is only 1–3 mm per linear meter, and this fact simply needs to be taken into account during installation.

These products are used not only for the facade - due to safety, it can be used for interior decoration, partitions, fences, benches, floor coverings for verandas, gazebos are made from it.

Types and technical characteristics

All facade panels must have quality certificates and appropriate fire safety documentation, so it is important to pay attention to this when purchasing.

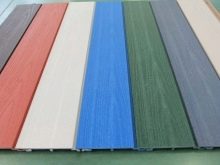

There are several types of WPC products:

- slatted board with a dense structure;

- planken - a similar dense material with additional grooves for the kleimer;

- siding is a product without internal surfaces;

- board with a honeycomb structure (hollow).

Different types of boards have their own texture, decoration, color, they can imitate wood and other materials, however, as a rule, have the same technical characteristics:

- the standard width is 20.4 cm;

- length can vary from 3 to 3.6 m;

- water absorption - 3%;

- weight loss during wear - 0.1 g / cm2;

- mechanical strength (bending) - 35 MPa;

- operating conditions - temperature from -50 to +70 degrees.

Such features of the material make it possible to install it in any weather conditions, but the manufacturer warns that it is advisable not to carry out installation at temperatures below +10 degrees.

Installation

Since the façade panels are lightweight, this makes installation much easier. In the future, you can replace the damaged plates with new ones, without the need to remove the rest of the materials.

For work, you will need the following tools: jigsaw or circular saw, mallet, building level, tape measure, marker.

The preparatory stage includes:

- cleaning the walls of the house from small litter;

- alignment;

- sealing cracks and cracks;

- primer.

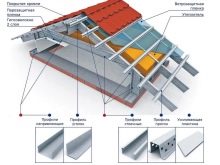

The first stage involves several steps.

- The frame is made of metal or wood materials. More durable and strong, as well as not requiring additional processing, is a metal profile.

- All details of the lathing are fastened with anchor bolts or nails. Thick-walled fasteners are used for metal parts.

- Installation of heat-insulating materials under the frame of the curtain facade may be relevant - in this case, you will have to install waterproofing as well. The work is carried out taking into account the thickness of the insulation.

At the second stage, the paneling is started in a strict sequence.

- They start from the bottom of the structure - holes are made in it, then a panel is applied and fixed with self-tapping screws, it is better if they are made of galvanized steel, they need to be inserted at right angles.

- You can fix the material with clips or do without them.

- As a result of heating, WPC products can expand, so it is important when laying the plates to leave a distance of 2-3 mm between them.

It is important that the composite panel is securely fastened every time it crosses the rail. Each row is mounted with a slight offset.

Facade panels from the German manufacturer Holzhof have special advantages. They have a hollow structure, therefore they are distinguished by increased reliability, strength and low thermal conductivity. In fact, this is a siding that has a hidden gap for high-quality ventilation, due to which optimal ventilation of the facade occurs.

This product has high quality indicators - high thermal insulation properties, low weight - 1.7 kg / m. etc., original colors (ivory, wenge, coffee with milk, dark beige). The texture assumes the presence and absence of grinding. In addition, these products have a longer service life - up to 30 years. In addition to being more economical due to their increased width, such slabs are also suitable for finishing wooden walls.

When choosing composite materials, first of all, it is worth paying attention to the accompanying quality certification, but there are also some subtleties that are important during installation - WPC panels are best mounted on facade walls that have a foot (based on the foundation), that is, a basement ... Hollow core panels are more suitable for facades where minimal stress on the structure is required. And one more important recommendation - facing the sunny side of the building will be more productive if you choose light shades of siding, since dark facade slabs fade more quickly, and this can be noticeable.

Using composite WPC facade panels for external walls, you can be sure of the high quality of strength and protection of the walls in any weather.

With the right approach to installation, the increased cost of the material fully justifies itself - such panels provide a long service life and an excellent appearance for any home.

For more information on WPC facade panels, see the video below.

The comment was sent successfully.