All about experimental materials

Knowing what these experimental materials are, and how exactly they are applied, is important for all developers. Only by understanding everything about experimental materials can you eliminate many problems and skillfully apply such products. Each of them has its own specific range of tasks to be solved.

What it is?

The story about building experimental materials should start with their definition. This category includes mainly the latest developments, which are supplied in very modest batches. The industry usually simply does not have time to master the production of sufficiently large volumes at first. Some time ago, experiments were carried out with gas silicate blocks and non-removable foam formwork. However, the situation is changing rapidly, and in 2020 professional builders will no longer be surprised by this.

It is generally believed that the experiment period ends after formal certification based on performance tests. It is unreasonable to think that all such decisions are unambiguously bad. Often, many of them, after certification, begin to be used very massively. It should be understood that new technological developments are not always sold under the brand of “experimental materials”. Some firms under this name sell something obscure - very old solutions, half-forgotten now, or bizarre combinations that are more likely to cause bewilderment.

Besides, the fate of each specific experimental material is unpredictable. Until recently, gas silicate and foam concrete blocks that were part of this group quickly gained popularity and became a familiar component of modern construction. But the clay, as it was in the experimental category, remains in it, despite its stable use. One way or another, all such materials are much more profitable than those used in large quantities.

One should be careful when buying houses built from EV: it may turn out that they were built according to the principle "what was - we do it".

Views

The most common solutions now are:

heat-wall;

expanded polystyrene;

liquid wood (it is also composite boards);

hyper-pressed Lego bricks.

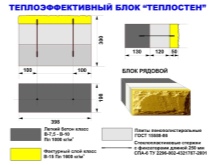

Name "Heat wall" speaks for itself. These are multilayer thermoblocks, which, along with simple concrete, include:

expanded polystyrene;

carbon fiber rods;

expanded clay concrete with a large number of pores.

As for the expanded polystyrene, then it is officially allowed only as an inner wall layer. However, some consumers use it as a permanent formwork. The prospects of such a decision will be shown in the near future. But the composite board is wood fibers mixed with polymer resin. This material is mainly used to decorate walls and floors.

Also sometimes found:

bags filled with earth;

pressed straw;

shell rock tyrsa.

But these three types of solutions will still rather be exotic for domestic developers, even those interested in non-standard methods. More often you can find buildings from cargo (for example, sea) containers. Competent decoration gives a good look and solves the problem of uniformity. But in addition, you will have to do some serious insulation in order to exclude the stifling heat in summer and the unbearable cold in February.A serious drawback of such a solution can also be considered insurmountable restrictions on the size of rooms in width and height.

Adobe houses are also considered experimental. During their construction, clay is mixed with straw and other plant fibers. Despite its antiquity, this approach is now experiencing a rebirth, since such a material is undoubtedly environmentally friendly. Old-type adobe huts are still found in Ukrainian, Moldavian and South Russian villages.

The breathing of such a material and excellent heat conservation are important, however, it must be understood that such material cannot be used without high-quality waterproofing.

Semisamanny buildings, erected in the 1970s-1980s, are found in the vicinity of Belgorod and Voronezh... The frame itself was built from oak planks. It was covered with clay and covered with bricks. The reason for this method of construction is obvious: at that time, full-fledged brick structures would have been prohibitively expensive. Another option for "radical savings" is the use of slate.

Strictly speaking, its classification as an experimental material is conditional. For roofing and finishing wall work, it has already been used in large quantities, moreover, for a long time. However, we are talking about a somewhat non-standard application:

a metal frame is being constructed, similar to that intended for gypsum board;

the wall inside the house is covered with chipboard;

the outer edge of the wall is covered with slate;

additionally, plastering is carried out, completely hiding this material.

In terms of external and consumer characteristics, such a solution is relatively good. NSit is practically impossible to determine what is under the plaster. However, using a wall for support (for example, attaching a ladder to it) is undesirable. Such houses are more designed for summer use. They are being actively built in the Crimea.

Fox hole construction Is another ancient achievement that has been tried in many regions of the world. But it is quite obvious that it will never leave the experimental stage. The formation of walls and ceilings involves the use of planks. Roofing material or birch bark is used for waterproofing.

Outside, all this is covered with soil; such buildings are rarely used for housing; in reality, the "fox hole" is used mainly in the format of a cellar or other outbuilding.

Appointment

One of the newest solutions is the development of the Japanese company Kengo Kuma. A double layer of leather membrane is used for finishing. This material provides excellent heat dissipation. The walls are built from Japanese larch. For outdoor insulation, fluorocarbon tarpaulins and bamboo stems are used.

For the construction of a house, the following can be used:

salt blocks;

plates "Isoplat";

glass facades with light blocking properties;

conductive concrete.

For roofs used:

modified roofing material;

polymer-based membranes;

shinglas;

katepal.

You can learn about what a building heat block is from the video below.

The comment was sent successfully.