Solvent R-12: composition characteristics

Solvent R-12 is a liquid consisting of three components. It is mainly used for thinning varnishes, paints, resin-based enamels, rubber and other substances. The wide application possibilities of the product were obtained thanks to modern equipment and high quality raw materials.

Composition

This transparent, slightly yellowish liquid contains the following components:

- xylene - aromatic hydrocarbon series (10%);

- toluene - methylbenzene, transparent liquid without impurities, industrial solvent (60%);

- butyl acetate - organic solvent (30% of the total composition).

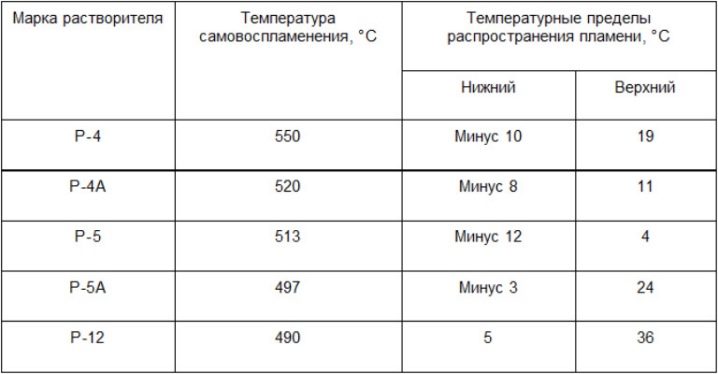

Main characteristics

The composition has a pungent specific odor that can have a negative impact on human health. The product is highly flammable, and its vapors evaporate for a long time. The use of a solvent in working with plastic is permissible, but the composition can "corrode" some of its types. Therefore, before use, it is necessary to test the effect on a small inconspicuous area of the surface.

If it is necessary to use other means in the work, it is important to carefully study their composition. Contact of Р-12 with powerful oxidants (for example, acetic and nitric acids, hydrogen peroxide) can lead to the formation of explosive substances.

Flammable mixtures are obtained by mixing with trichloromethane and tribromomethane.

The technical characteristics by which such compositions are evaluated include several points.

- The volatility coefficient, or the rate of evaporation with respect to ethyl ether, determines how toxic a mixture is. The product in question belongs to medium volatile solvents, the coefficient is 8-14 g.

- Karl Fischer titration is a method of analytical chemistry, the essence of which is to determine the proportion of water in the composition under study. In the R-12 solvent, it is no more than 1 percent.

- Acid number - the mass of caustic potassium required to neutralize 1 gram of organic matter, measured in milligrams. For R-12, it is no more than 0.10 mg KOH / g.

- The number of coagulation funds is at least 22%. With its help, the dissolving capacity is determined in a quantitative measure.

- The relative density of the product is 0.85 g / cm3, it increases with heating. An increase in temperatures promotes a decrease in the composition of the organic solvent. This factor affects the purity of the mixture.

- The flash point in a closed crucible is not lower than +5 degrees Celsius. It determines the temperature at which the mixture vapors will ignite in a closed refractory vessel. In accordance with the norms, a temperature of no more than 28 degrees characterizes the liquid as especially dangerous.

When mixing the solvent with paints and varnishes, the components should not coagulate or delaminate. If this happened, then either the compositions are incompatible, or the proportions were violated during the breeding technology. This will also be evidenced by the appearance of whitish or dull spots on the dried surface. After drying, the film should remain shiny and even.

Application area

The production and use of R-12 is carried out in accordance with GOST 7827-74.

This document defines that the solvent is used for dilution:

- paints and varnishes (LM) based on PSC LN or PSC LS;

- polyacrylic resins;

- a variety of synthetic or natural substances, upon application of which a film is formed on the surface.

Despite the clearly marked points, this tool is also often used for cleaning tools, used for aquaprint. Some people resort to using it in everyday life, removing "difficult" stains.

In auto repair shops, R-12 is usually used for diluting base and acrylic car enamels. The composition does not change the properties of such paints. They lie flat on the surface, do not lose color and other characteristics. Dilution of acrylic enamels is justified by the fact that they are based on acrylic resins, and not water-based compounds.

Special attention should be paid to the use of R-12 in the technology of applying aquaprint. One of the stages of this work is activation. To apply the pattern, it is necessary to soften the immersion film. Professionals use special formulations, but for amateurs this type of solvent is a good and inexpensive replacement. It is evenly sprayed over the entire surface from a spray bottle or in another way.

The solvent of this brand is also used as a replacement for other mixtures, for example, the R-5 solvent. Paints and varnishes must be mixed with the solvent gradually, adding it in small portions, constantly stirring the composition. The mixing ratio is determined according to the manufacturer's instructions.

In the automotive industry, old layers of acrylic paint are also removed with solvent. It must be applied in a thin layer (no more than 2 mm) and wait about 10 minutes. The coating gradually softens and can be easily removed with a spatula.

Safety regulations

The composition of this solvent determines the toxicity and high flammability of the mixture, therefore, all safety rules must be observed when storing and working with it.

It is necessary to store the R-12 solution with a tightly closed lid., in places protected from children. It is also important to limit direct sunlight exposure to the product. The room must be well ventilated. Do not place the solvent near heating and electrical appliances, as well as sharp objects (to avoid puncture of the package).

When working directly with the composition, protection of hands and eyes is mandatory. It is necessary to wear gloves and special glasses, since the components of the solution can cause severe chemical burns if they come into contact with open parts of the body.

It is necessary to work outdoors or in a well-ventilated room (if ventilation is poor, wear a respirator). Since the air is lighter than the vapors of the mixture, they are deposited on the floor and surrounding surfaces. Therefore, after completing all actions with the P-12, it is necessary to wash the work area in order to prevent unwanted ignition.

If the product gets on the skin, it is washed with plenty of running warm water using soap. If the composition gets into the eyes, they are thoroughly washed with water and immediately consult a doctor.

For more information on the properties and uses of P-12 solvent, see below.

The comment was sent successfully.