Solvent R-4: properties and application features

The use of varnishes and paints in production and everyday life is often inconvenient due to their high density and viscosity. This inconvenience is easily removed by the solvent.

And also it is needed to remove paint stains, degrease surfaces, wash brushes after work. The R-4 will do just fine with all these tasks.

Features and composition

Any solvent either belongs to the group of active chemicals, or is a mixture of several components. Such a mixture of substances of organic origin is P-4.

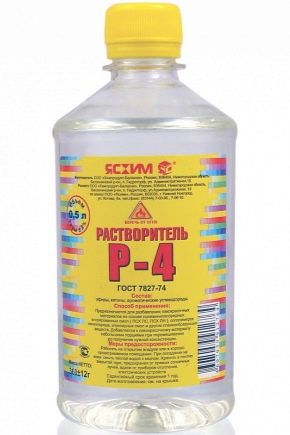

It looks like a clear, colorless or yellowish liquid.free of sediment or suspended particles. The substance has a pungent characteristic odor.

It has gained great popularity as it has good consumer properties. P-4 is on sale in any specialized store at an affordable price. In addition, having a wide range of applications, it is very easy to use. A description of the method of application and composition are usually indicated in the instructions on the container with the substance.

One of the features of R-4 is the possibility of its use for the dilution of almost any paint and varnish materials, making them economical to use. And also P-4 gives them the ability to dry faster, and when dry forms a smooth shiny film that prevents the coating from fading.

It is necessary to ensure that no water gets into the solvent during operation. It will mix with acetone and this will cause white spots to appear on the painted surface after drying.

Acetone and toluene are required ingredients in the solvent. There are 26 and 62% of them in P-4, respectively. They expand the scope of its application. And also butyl acetate is added to the composition, which helps to prevent painted surfaces from fading.

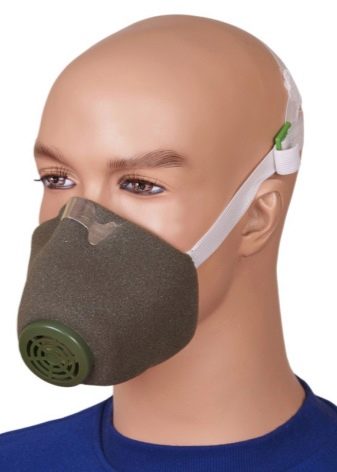

However, these substances cannot be called useful for the human body. Although contact with the solvent on the skin does not cause burns, prolonged contact with it and inhalation of vapors will not go unnoticed: poisoning, dizziness, coughing, and dermatitis may occur.

Therefore, respiratory protection measures should be taken when handling solvents. And also you need to avoid getting liquid in your eyes. Work should be carried out in a well-ventilated area; gloves or mittens will be useful.

Specifications

Solvent R-4 is a volatile self-igniting substance. However, spontaneous combustion occurs at a fairly high temperature - above 500 degrees C. Nevertheless, it is a flammable substance, and requires careful handling. Do not smoke near it, open flames and sparks are unacceptable.

One should take into account such an important indicator as the flash point. This term denotes such a temperature indicator at which solvent vapors mixed with air vapors ignite in the presence of an open flame. For P-4, the flash point is -7 degrees C.

During production, the substance is packed in a container, the walls of which will not enter into a chemical reaction with it. This is usually glass or plastic packaging. It is necessary to store the solvent in dark rooms where there is good ventilation so that it is not exposed to direct sunlight and moisture. The container should be tightly closed, and there should be no electrical or heating devices nearby.

The technical characteristics of the solvent are determined by GOSTs. They are usually indicated on the packaging. For P-4, these are:

- coagulation number - 24%;

- part of the water - 0.7%;

- volatility - 5-15;

- density - 0.85 m3;

- ignition temperature - 550 degrees C;

- flash point - minus 7 degrees C.

Solvent packaging can be small or large. It depends on where it will be applied.

For domestic use, it goes on sale in containers of 0.5, 1, 3, 5, 10, 20 liters. In a bottle with a capacity of 0.5 liters, the weight of the product will be 0.4 kg. In other containers - 0.7, 2.2, 3.7, 7.2, 14 kg according to the indicated volumes.

For industrial use, large packaging is used. It can be 100 and 216 liters. In it, the weight of the product will be 72 and 165 kg, respectively.

The volume of containers and the weight of the product in it may differ from different manufacturers. Manufacturers set a guaranteed shelf life of the product at one year from the date of manufacture.

Scope of application

R-4 is extremely popular among people involved in the renovation of premises, as it is practically universal and necessary for a wide range of works.

Most often it is used for painting., since it is very effective for the high solubility of paints and varnishes used in interior decoration. It was specially developed for materials based on vinyl chloride, epoxy, PVC and chlorinated resins. It is suitable when it is necessary to dilute or dissolve synthetic or natural film-forming compounds.

It should be noted that the use of a solvent significantly reduces the cost of repair work, since its price is low, and the consumption of paint in a more liquid consistency is significantly reduced. In this case, the quality of the staining does not suffer.

Although the main purpose of the solvent is to thin varnishes and paints, it can be used to clean and degrease surfaces. To do this, wipe them with a cloth soaked in solvent.

Contamination comes off very easily and the solvent evaporates quickly, leaving a thin film. The resulting film is an excellent protective coating that will ensure the subsequent high-quality staining of the surface.

To prevent brushes and other tools from being damaged, they must be washed after work. However, this cannot be done with soap and water. R-4 will come to the rescue here too.

Degreasing is also necessary for many other non-staining work. For example, for the subsequent application of glue or other compounds when repairing shoes, furniture or appliances, when gluing broken fragments. The degreasing procedure can be carried out using P-4.

Manufacturers

There are many manufacturers on the market today who, among other products, produce solvents.

One of the largest Russian enterprises - Dmitrievsky chemical plant.

Its history began over a century ago. In 1899, a small manufactory producing acetic acid and its salts was founded by Savva Morozov. Over a long development path, it has turned into a modern company that manufactures products for various industries. The company continues to develop and monitors its reputation, exercising control over the quality of products at every stage of its manufacture. Therefore, many products, including P-4, are in demand not only in the domestic market, but also in 70 countries around the world.

Another well-known large manufacturer is a Belarusian plant "Naftan".

This is a relatively young company, its construction began in 1958. February 9, 1963 is considered his birthday, when gasoline was produced for the first time in Belarus. The enterprise developed by leaps and bounds, technologies are constantly being improved, the efficiency of production processes is increasing.

In addition to production facilities, the plant has a system of tank farms, an overpass where raw materials are received and products are shipped, as well as a developed transport network along with the railway.

The plant produces an assortment of products of 70 items for various industries.There are different brands of solvents in the product list, including P-4. For domestic use, the product is packaged in glass bottles with a capacity of 1 and 2 liters.

Consumption

So that the applied paint does not later begin to flake off due to uneven application and lumps, it must lie on the surface in an even layer. The added solvent will solve this problem.

There are regulatory documents to determine the solvent consumption. Some time ago they were convenient to use. However, at present there is a huge assortment of paints and their manufacturers, so you should definitely follow the recommendations from the manufacturer. Each type of paint and varnish products may have its own nuances. The material of the surface to be painted, the temperature and humidity of the environment, the type and "age" of paint, enamel, primer or varnish and their brand, method of application can be taken into account.

For example, for varnish XB-784 or enamels XB-124 and XB-125, 50% of the solvent from the mass of paint or varnish will be required for pneumatic application and 25-35% - airless. These products are not applied with a brush. If you apply these enamels with a brush, the solvent consumption will be 13-15%.

To find out how much solvent you need, you must first calculate the amount of paint you need. Manufacturers, as a rule, indicate on the packages information about the size of the area for which 1 kg or 1 liter of paint will be needed. It is more convenient to use the indicator of material consumption per 1 m2. Usually, these indicators differ not only for different types of paint, but also for different colors of paint of the same type.

For oil formulations, the spreading rate is also important. It shows how thick the dried layer should be after painting, at which this layer will not be transparent. All these indicators take into account the amount of the finished, that is, diluted, composition. Having calculated its quantity, taking into account the area and quality of the surface, you can calculate how much paint you need to buy and the consumption of solvent.

For example, to decorate a room, you need 10 liters of the composition. If you apply the paint in an economical pneumatic way (where 50% of the solvent is needed), then using not the most tricky calculations you will determine the ratio of the components. Since in this case you take 100% paint and 50% solvent, then in 10 liters they will be 150%. Make a proportion and make calculations. It turns out that you need about 3.3 liters of solvent, and 6.6 liters of paint.

If you use a brush when you need 15% solvent for mixing, then 10 liters of it will need 1.3 liters, and for paint - 8.7. Do not forget that after work you will need to wash the brush and wipe off any dirt.

In order to properly prepare the paint and varnish material, it is necessary to add small portions of the solvent to it until the varnish or paint acquires a suitable consistency. This requires constant mixing of the composition.

Analogs

If it happened that all the solvent ran out, and the nearest P-4 store was not, then the trouble is small.

You can finish the work using its counterparts.

- First of all, pay attention to the P-4A. It has the same properties as P-4, it is its closest analogue. They have a similar composition and scope. It differs from P-4 in the absence of butyl acetate in the composition. Thanks to this fact, P-4A can be used with HV-124 enamel.

- You can replace P-4 with P-5 or P-5A. They have a slightly wider scope. They can be used for materials based on rubber, organosilicon, polyacrylic resins. R-5 contains 40% toluene and 30% butyl acetate and acetone.

- And also the "relative" of R-4 is the R-12 solvent. It differs from P-4 in that there is no acetone in its composition, it is replaced by xylene. It has a lower flash point. It is 490 degrees C. R-12 should be used with caution if other substances are used for work.The fact is that when mixed with some (hydrogen peroxide, acetic or nitric acid), it is capable of forming explosive mixtures.

P-12 suitable for working with various types of paints and varnishes, with film-forming substances. It is widely used in car repair shops, where they are diluted with car enamels. And also with its help, old acrylic paint is removed from cars. To do this, the paint is moistened with the product and wait 10-15 minutes, and then the softened layer is removed with a spatula. R-12 is used in everyday life for cleaning tools, removing stains. It should be noted that R-12 is aggressive towards some types of plastics.

Solvent R-4 can be replaced with other brands. Here you need to pay attention to the composition and technical characteristics. If the compositions of paints and varnishes and solvents are incompatible, then their components can coagulate or delaminate. For the selection of compatible formulations, it is better to seek advice from a specialist.

It should not be forgotten that analogues of R-4 are also flammable and toxic substances, and it is necessary to observe safety measures during work, and they must be stored in proper conditions.

For more information on the P-12 solvent, see the video below.

The comment was sent successfully.