Features and application of liquid glass

In the process of repair and finishing work, one cannot do without high-quality adhesives. Fortunately, today the choice of such products is great and choosing the right option is not difficult. Among the rich assortment of different types of glue, it is worth highlighting liquid glass. Today we will talk about the features and subtleties of using such a composition.

What it is?

Every person is familiar with ordinary glass. This material appeared over 5000 years ago in Egypt. However, not every consumer is aware of what constitutes liquid glass.

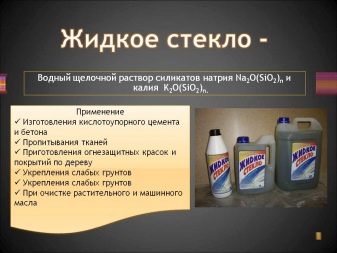

Another name for this composition is silicate glue. It consists of water and silicate salts. For the manufacture of such an adhesive mixture, the same components are used as in the production of glass products.

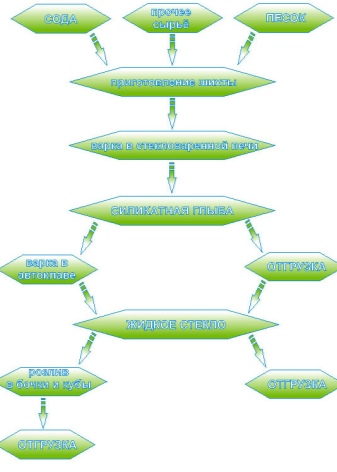

At the moment, there are several technologies for the production of liquid glass. The most popular of these is the effect of solutions on materials containing silica at constant temperatures.

Peculiarities

Nowadays, the range of finishing materials is striking in its diversity. Thanks to a wide selection of different mixtures and compositions, craftsmen are able to carry out almost any repair work. So, one of the most popular and demanded adhesives is liquid glass. These products can be used for a variety of purposes. In addition, the use of quality liquid glass can extend the life of a building.

This high-tech silicate glue is made on the basis of sodium, potassium or lithium. The last component is the least commonly used.

The main feature of liquid glass is that it can easily penetrate the structure of rigid materials. At the same time, this adhesive gives off its moisture, increasing the degree of viscosity and density.

Such a composition is characterized by increased adhesive properties. It is also distinguished by thermal conductivity. Due to these features, this silicate adhesive is often used during thermal insulation work. The insulation, which was installed using liquid glass, is capable of withstanding record temperatures of up to 1200 degrees Celsius.

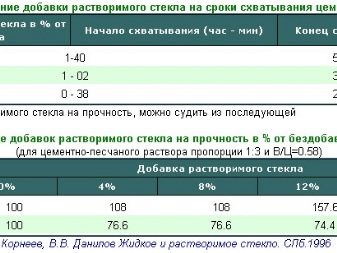

Liquid glass can improve the performance of other materials. For example, it is often mixed into concrete. Such a mixture can be used for the construction of various structures that will regularly come into contact with dampness and moisture.

Silicate adhesives are used not only for repair work. They can be purchased for installation of various finishing materials, surface treatment for additional fire safety, as well as for polishing substrates that need it. It is worth noting that liquid glass is distinguished by a special structure that can make any surface smooth and shiny.

Advantages and disadvantages

Dignity

Silicate composition is a popular and demanded material. This is due not only to the wide range of its applications, but also to the many positive qualities that are inherent in this composition.

- Liquid glass applied to a particular base, after drying, repels dampness and moisture, thereby such a mixture plays the role of a high-quality water repellent.

- Such formulations destroy harmful bacteria, and also prevent their occurrence in the future. This means that liquid glass is a good antiseptic.

- Liquid glass prevents static electricity from appearing on the surface of the base. Thanks to this characteristic, dust does not accumulate in the areas treated with such a product.

- If there are various defects on the base, for example, cracks, then it should be treated with water glass. In this case, this adhesive composition will fill in the damaged areas, and also make the base more durable.

- Such mixtures have a suppressive effect on acids and protect bases from fire, making them more fireproof.

- Many consumers have noticed the economical consumption of liquid glass. Of course, a lot depends on the master himself.

- Liquid glass boasts excellent anti-corrosion properties.

- This material is in good contact with mineral bases.

- The demand for such adhesive mixtures is explained by their democratic cost. Everyone can afford high-quality liquid glass.

- Such formulations are distinguished by a long service life. They do not lose their beneficial qualities even after many years from the moment of application.

- Using liquid glass, you can significantly extend the life of concrete and paint coatings.

- These compounds are resistant to abrasion.

- In addition, liquid glass boasts excellent adhesion properties. It adheres easily to a wide variety of materials, from drywall to concrete.

- It is quite easy to work with this adhesive composition, as it fits seamlessly on any substrate.

disadvantages

According to most home craftsmen, working with liquid glass is a pleasure. However, this material is not ideal.

It also has its own shortcomings, which must be taken into account during repair work.

- The main disadvantage of liquid glass is the presence of a large amount of alkalis in its composition. These ingredients have an adverse effect on the skin, therefore it is recommended to work with such adhesive mixtures with high gloves, as well as in protective clothing and shoes.

- Experts also refer to the list of shortcomings that liquid glass sets too quickly with other surfaces. This material hardens in literally 20 minutes, after which it can no longer be used. Because of this, you have to work with such mixtures as quickly as possible.

- Liquid glass can be used for waterproofing not in all cases. These works can be performed only if the base is in an easily accessible place, for example, on the surface of the foundation.

Views

At the moment, there are several varieties of high-quality liquid glass. Each of them is used for different purposes and has its own characteristic features.

Sodium

Soda glass is a highly viscous solution based on sodium salts. Such a material has excellent adhesion characteristics, as well as increased strength and durability. It can be applied to materials with a wide variety of structures. Sodium mixtures are not afraid of temperature changes. In addition, they are non-flammable and non-deformable.

For sodium adhesives, some features are characteristic.

- Such mixtures dry very quickly - within 10 minutes.

- If the material is frozen, you can add more water to it and stir it well so that it can be used again.

- Soda water glass is a material that is quite often used when laying tiles. In this case, sodium silicate is diluted with water for a quality primer.

- If a simple liquid glass was applied to the base before laying the sodium composition, then you should not wait for it to dry - the hardened glassy film will interfere with sufficient adhesion of materials.

Sodium adhesives are used both in construction work and in everyday life, for example, for cleaning dishes, removing various stains or plumbing work.

Potassium

This kind of silicate glue is based on potassium salts. The structure of such an adhesive is rather loose. In addition, these mixtures are highly hygroscopic. Surfaces covered with potassium water glass are not afraid of overheating and mechanical damage.

Such mixtures have the following properties:

- they create excellent adhesion;

- they are not afraid of temperature jumps;

- high-quality potassium composition can protect the base from aggressive chemicals;

- protects the base from the appearance of defects such as fungus and mold;

- significantly increases the resistance of the base to abrasion;

- easily enough absorbs excess moisture, especially if you compare the potassium composition with sodium;

- does not melt under the influence of high temperatures;

- forms a denser and more elastic coating on the base;

- after hardening, it acquires a matte surface that does not have spots or reflections.

Lithium

Lithium glass is a limited quantity product. Due to their special structure, such formulations can provide excellent thermal protection for all substrates.

Scope of application

Liquid glass is used in various fields of activity, therefore it belongs to the universal materials.

Silicate mixtures are very often used for high-quality waterproofing of various materials. Walls and foundations are often treated with such compositions, and not only public and private buildings, but also garages, which also require sufficient waterproofing.

High-quality liquid glass makes certain bases moisture resistant. In conditions of increased dampness and humidity, the treated coatings will not collapse or deform.

Liquid glass is rightfully recognized as one of the most effective and efficient antiseptic agents. It can be installed on walls, floors and ceilings indoors. Thanks to competent processing with such a composition, these surfaces will not be subject to the formation of mold and mildew, which can be very difficult to get rid of.

It is worth noting that liquid glass can be used not only to prevent, but also to remove fungal formations, if they have already started on the walls / ceiling / floor. It is enough to treat the damaged base with such an adhesive solution, after which the destructive defects will simply disappear from its surface.

Due to such abilities, liquid glass is very often used to prepare floors for future wallpapering. In this case, antiseptic treatment is a prerequisite, especially if the canvases are not breathable.

In the construction industry, you also cannot do without high-quality liquid glass. In this case, the waterproofing properties of the material come in handy. In addition, silicate adhesive mixtures can be used in attics and basements.

Liquid glass is irreplaceable in repair workbecause it provides outstanding protection for concrete structures. It can be applied to a variety of substrates including screeds and concrete blocks. After such treatment, such surfaces become more durable, moisture resistant and fireproof.

Silicate products are also used for the treatment of wells. As a rule, such work is carried out in two stages. First, the finishing material is laid on the partitions, and then it is covered with sand-cement mortar and liquid glass.

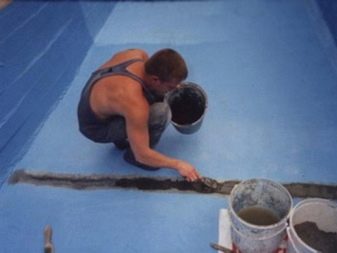

Also, liquid glass is a suitable material for the treatment of the inner walls of the pool. The film formed after application is capable of protecting such structures from damage and leaks. According to experts, for processing such bases (both outside and inside), 2-3 dense layers of liquid glass should be applied.In this case, such a composition can be used both in undiluted form and supplemented with various components.

However, it should be borne in mind that liquid glass cannot be applied to brick bases, since this material can lead to the gradual destruction of the masonry. For such structures, it is better to use a special PVA building composition.

Liquid glass is purchased not only for repair work. So, sodium and potassium mixtures are often used for simple household purposes. Since these mixtures adhere seamlessly to most different surfaces, they are used when laying PVC panels and linoleum.

When it is necessary to lay metal pipes in the room, liquid glass can be used as a sealant for communications.

Various fabrics are also impregnated with liquid glass. Such processing is required for the textile to be non-flammable. In addition, many owners use these compounds to protect the tree (trunks and branches) from pests.

Similar adhesive mixtures can be used to polish various surfaces. They can be applied to the surface of tables, cabinets, shelves and other suitable substrates that you want to give a more presentable and shiny look. Also, using liquid glass, it is permissible to repair damaged glass and porcelain parts.

Liquid glass is often used as an additional ingredient in the manufacture of beautiful self-leveling floors with a 3D effect. In addition, these clear mixtures are used by car fitters as they can be used on car bodies. For this, a two-component substance is often used with an optimal ratio of hardness, hydrophobicity and gloss.

Other areas of application

- liquid glass is used in the design of stretch ceilings;

- mirrors;

- ceramic tiles;

- mosaic panels;

- stained glass canvases.

How to cook?

Today in stores you can find both ready-made liquid glass and compositions that you need to prepare yourself. Of course, most buyers prefer ready-made options, although they are not so common - water glass is more often used as an additive for the preparation of a certain solution. However, they are more expensive and must be consumed completely, otherwise the composition will simply dry out.

It is much cheaper to use individual components, so the manual preparation of liquid glass remains relevant for many craftsmen.

Self-preparation of liquid glass is a simple process that everyone can handle.

To do this, you need to purchase the following devices and materials.

- Bucket. It is worth taking a separate container that you plan to use only for construction work. The toxicity level of silicates is not too high, but it is recommended to keep them away from foreign objects such as fruits or vegetables.

- Electric drill with auger attachment. This tool is ideal for mixing very thick solutions.

- Brush or spray bottle.

- Cement. In this case, it is quite possible to get by with simple Portland cement.

- Fine sand.

- Water.

- Putty knife.

- Protective clothing.

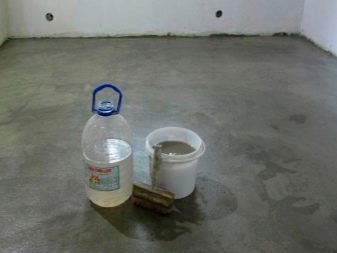

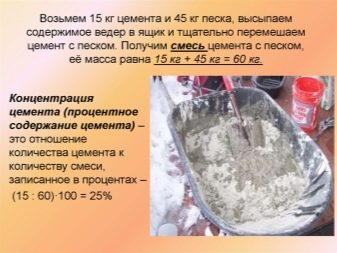

Mix liquid glass with water and other listed components in accordance with the proportions required for specific work. If the base on which the mixture is to be applied reduces its adhesion level, then it is recommended to use less water or add more cement.

You can dilute liquid glass with plain cold water. To keep the amount under control and not overflow, it is recommended to use special measuring cups of sufficient volume.

As a rule, water is first poured into the container, and then cement is poured. These components are thoroughly mixed and water glass itself is added to them. Use a handy construction mixer to stir the mortar as soon as possible.Try to knead the composition quickly, without being distracted by other things, since it will dry in half an hour - you do not have much time. Of course, if you can't fit at this time, it is worth adding more water to the mixture in a small amount.

For the manufacture of a waterproofing compound, you need to take one part of fine sand, water glass and Portland cement. The listed ingredients must be poured into a container with already poured water. After that, all components must be mixed well.

As for the preparation of the refractory composition, the process of its preparation consists of two stages.

- First, you need to make a mixture of three parts sieved sand and one part Portland cement.

- Next, water glass should be added to this mixture. In this case, this component is mixed in at the rate of 25% for the entire volume of the composition.

Such solutions can be safely used to create high-quality stoves or fireplaces.

You can also prepare an antiseptic solution with your own hands. It is simply necessary when it comes to protecting wooden surfaces that are prone to decay. In this case, the material must be diluted 1: 1 with water. Such a mixture is ideal for concrete, plaster or stone structures.

To strengthen the main surface, you need to prepare a solution consisting of 1 liter of water and 300 g of liquid glass. However, it should be borne in mind that in the process of processing, you can achieve a greater effect if you apply a similar solution in 3 or more layers. Remember to take breaks between laying each layer.

According to experts, it will be better if you mix dry mixtures first, and add liquid to them only later. As a result, you should have a liquid and uniform mixture.

How to apply?

Application of liquid glass does not require special knowledge and rich experience. The main thing is to adhere to simple instructions, and then such work will not take much of your time and effort.

Let's consider how to use such a mixture using the example of processing walls covered with soil.

- The pre-prepared primer should be applied to a particular substrate only after you have removed dust and any dirt from it.

- When the base is perfectly clean, take a roller (or brush) and then apply the first coat of primer to the surface to be treated.

- Be sure to wait for the first layer applied to dry. After that, you can proceed to smearing the base with a second layer of finishing material. Avoid leaks or leaks.

- Now you need to prepare a protective composition of cement, sand and liquid glass. Mix all the ingredients well. Wait until the primer is completely dry on the substrate.

- After that, the solution must be immediately applied to the finished wall with a spatula. When carrying out such work, you should wear special protective goggles, gloves and overalls.

- As a result, you just have to wait until the liquid glass on the finished wall is completely dry.

Manufacturers

Currently, there are many large and well-known manufacturers on the building materials market that produce high-quality liquid glass. Many of them offer a delivery service for this practical material.

Let's take a closer look at some manufacturers.

"ChemStroyResource"

This manufacturer manufactures liquid glass on an industrial scale. The products manufactured by "KhimStroyResource" comply with all quality standards and comply with GOSTs.

The range of this large manufacturer consists not only of liquid glass, but also epoxy glue, furfuryl alcohol, acid-resistant tiles / bricks and acid-resistant nozzles. The cost of the products of the company "ChemStroyResource" is affordable.

"Metterra"

It is a large Russian manufacturer of liquid sodium glass.The enterprise of the same name produces high-quality products with a density of 1.2-1.5 g / m2 and a module from 2.6 to 3. According to the manufacturer, its liquid glass is environmentally friendly and absolutely safe.

Metterra offers liquid glass in customer containers, as well as barrels with a volume of 200 liters and cans from 10 to 100 liters. At a temperature of -15 degrees, the compositions of this manufacturer can be stored for about 30 days.

"GlassProduct"

Trading house "StekloProdukt" is engaged in the manufacture and sale of quality products. The assortment of this brand includes foam glass, silicate lumps, glass bottles and liquid glass. Currently, the products manufactured by this company are used in many industrial enterprises.

"StekloProdukt" manufactures sodium composition taking into account all requirements and quality standards. The production process of liquid glass is subject to constant checks at every stage, so the risk of releasing defective products is excluded.

Storage and safety

Silicate glue is not a hazardous and toxic material, but when working with it, you must follow a number of simple rules.

- Work as carefully as possible. Do not allow liquid glass to come into contact with exposed skin. In addition, it is necessary to protect the mucous membrane and eyes. Avoid splashing when applying protective compound.

- The mixture of liquid glass must be prepared with high gloves and glasses.

- Always close jars and other containers as tightly as possible, in which liquid glass is stored or stored. This should be done immediately after using the material - do not leave the container open.

The shelf life of this adhesive is 1 year. It is permissible to subject such a material to repeated freezing, this will not affect its performance in any way. During storage, sediment may appear, but this is considered normal.

Advice

Most consumers leave extremely positive feedback on the use of liquid glass. This material is easy to apply to many substrates, after which they become more durable and look smooth and neat.

If you also decide to turn to such useful and practical solutions, then you should heed some expert advice.

- If you decide to independently apply liquid glass to one or another base, then you should thoroughly degrease it. With this preparation, the adhesive mixture will adhere better to the coating of the substrate.

- In the process of mixing the solution, make sure that no foreign particles or debris get into it. This can adversely affect the adhesion of the coating.

- It is not recommended to apply liquid glass to the base under plaster or paint. In this case, the resulting film will interfere with further processing.

- If you want to reduce the hardening properties of the mortar, then first you need to mix water glass and water, and then add the cement-sand mixture.

- Do not violate the proportions of the components for the preparation of liquid glass. Such errors can lead to ineffectiveness of the resulting composition.

- If you have applied a silicate compound to the car body, then it is recommended to renew it about once a year, despite the fact that manufacturers guarantee the retention of this material on the car for 3 years.

- Silicate products can be used when pruning garden plants. For this, damaged elements are processed with similar compositions. Thanks to this treatment, the plants do not rot.

- Try to drip liquid glass onto other surfaces that you do not intend to cover with it. Many consumers are wondering how to remove such a composition from other bases. There is no single way to remove liquid glass, but some users advise to rinse it with hot water and rub it until it is completely removed. Some use a razor to rub off this mixture, while others use vinegar to dissolve it.

For information on how to apply liquid glass to concrete with your own hands, see the next video.

The comment was sent successfully.