Features of bituminous mastics "TechnoNICOL"

TechnoNIKOL is one of the largest manufacturers of building materials. The products of this brand are in great demand among domestic and foreign consumers, due to their favorable cost and consistently high quality. The company produces a variety of materials for construction. One of the sales leaders are bitumen-containing mastics, which will be discussed below.

Scope of application

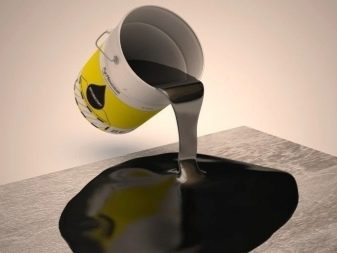

Thanks to TechnoNICOL bitumen mastics, it is possible to create seamless coatings that provide reliable protection of the object from moisture penetration. These materials are often used for roofing work.

They are used for:

- strengthening shingles and fixing roll roofing;

- repair of a soft roof;

- protect the roof from overheating when exposed to sunlight.

Bituminous mastics are used not only for roofing work. They have found wide application in the arrangement of bathrooms, garages and balconies. Also, these materials are used in the elimination of interpanel seams, for waterproofing pools, foundations, shower rooms, terraces and other metal and concrete structures.

In addition, mastic is able to protect metal products from corrosion. For this purpose, various parts of automobile bodies and pipelines are covered with the composition. Sometimes bituminous mixtures are used for the reliable gluing of thermal insulation boards, laying parquet or fixing linoleum coverings. Bitumen-based mastic is widely used in construction and repair work.

However, its main task is to protect the structure from moisture penetration by atmospheric precipitation and increase the service life of the roof.

Features: advantages and disadvantages

Due to the use of TechnoNICOL bitumen mastics, it is possible to create a reliable protective film on the treated surface. This eliminates the formation of seams or joints. Bitumen-based compounds are allowed to be applied on unprepared substrates: wet or rusty, thereby reducing the time of waterproofing work.

Possessing high adhesion, mastics quickly and reliably adhere to any surfaces: concrete, metal, brick, wood and others. Due to this feature, the applied composition will not peel off and swell over time.

Other advantages of bituminous mastics include the following characteristics:

- high tensile strength (especially in rubber and rubber compounds), due to which the deformation of the base is compensated (for example, prevention of "creeping" of joints during temperature fluctuations);

- the layer of mastic is 4 times lighter than the roofing roll waterproofing;

- the possibility of using the composition on both flat and pitched surfaces.

The operational characteristics of TechnoNICOL mastics include:

- ease of application due to the elasticity of the material;

- economical consumption;

- insolation resistance;

- resistance to aggressive substances.

All bituminous compositions have good physical and mechanical properties. And the inexpensive price and prevalence makes these materials available to any segment of the population.

The disadvantages of bituminous mastics are insignificant. The disadvantages include the impossibility of performing work in atmospheric precipitation and the difficulty of controlling the uniformity of the applied layer.

Views

Many varieties of bituminous mastics are produced under the TekhnoNIKOL trademark, which are used in various fields of construction.Such materials are classified by both composition and method of use.

The latter classification includes hot and cold mastics.

- Hot mastics are a plastic, homogeneous and viscous mass. The main components of the material are asphalt-like components and binders. On some packages there is letter marking A (with the addition of an antiseptic) and G (herbicidal component).

Hot mastic needs to be warmed up (up to about 190 degrees) before being applied to the work surface. After hardening, the product forms a reliable highly elastic shell, eliminating the risk of shrinkage during operation. The main advantages of the material include a homogeneous structure without pores, the ability to work at negative ambient temperatures.

Its disadvantages are an increase in construction time and high fire risks associated with heating the bitumen mass.

- Cold mastics are considered easier to use. They contain in their composition special solvents that give the solution a liquid consistency. Due to this feature, the materials do not need to be preheated, which simplifies construction activities and reduces the associated costs.

In addition to these advantages, cold mastic is in great demand due to the ability to dilute the composition to an optimal consistency and color the solution in the desired color.

When hardened, the material forms a strong waterproofing shell on the surface, which is resistant to precipitation, sharp temperature fluctuations and to the effects of sunlight.

Classification of mastics by composition

There are several types of cold-use bituminous mastics, classified according to their constituent components.

- Solvent based. These are ready-to-use materials that can be handled at sub-zero temperatures. The agent applied to the surface hardens after a day due to the rapid evaporation of the solvent. The result is a monolithic waterproofing coating that reliably protects the structure from moisture.

- Water based. Water-based mastic is an environmentally friendly, fire- and explosion-proof product with no odor. It is characterized by fast drying: it takes several hours for it to completely harden. Emulsion mastic is easy to apply, it is absolutely non-toxic. You can work with it indoors. The disadvantages of emulsions include the inability to use and store at low temperatures.

There are also several types of bituminous mastics.

- Rubber. Highly elastic mass, which received the second name - "liquid rubber". Effective, durable and weather-resistant materials that can be used as a stand-alone roof covering.

- Latex. Contains latex, which gives the mass additional flexibility. Such emulsions are subject to coloring. Most often they are used for gluing roll cladding.

- Rubber. Includes a rubber fraction. Due to its anti-corrosive properties, it is used for waterproofing metal structures.

- Polymeric. The mastic modified by polymers has increased adhesion to any substrates, it is resistant to temperature fluctuations and negative weather influences.

You can also find unmodified solutions on sale. They do not contain improving additives, due to which they quickly lose their performance during heating, freezing, temperature extremes and other factors. Such features do not allow the use of unmodified emulsions for roofing. Their main purpose is to waterproof foundations.

In accordance with the number of components, mastics can be one-component and two-component. The first is a mass completely ready for application. Two-component polyurethane - materials that need to be mixed with a hardener. These formulations are intended for professional use. They have higher technical characteristics.

Assortment overview

TechnoNICOL produces an extensive line of bitumen-based mastics designed for various types of construction work. The most common waterproofing products include some of them.

- Rubber-bitumen mastic "TechnoNIKOL Technomast" No. 21, the composition of which is made on the basis of petroleum bitumen with the addition of rubber, technological and mineral components, as well as a solvent. Suitable for machine or hand application.

- "Road" number 20. It is a bitumen-rubber material based on petroleum bitumen and organic solvent. It can be used at negative temperatures both indoors and outdoors.

- "Vishera" number 22 Is a multicomponent adhesive mass intended for fixing roll coverings. Contains bitumen modified with polymers, solvents and special technological additives.

- "Fixer" No. 23. Tiled mastic with the addition of thermoplastic elastomer. The composition is used in construction work as a waterproofing or adhesive.

- Water-based composition No. 31. It is used for both outdoor and indoor work. Produced on the basis of petroleum bitumen and water with the addition of artificial rubber. It is applied with a brush or spatula. The best solution for waterproofing bathrooms, basements, garages, loggias.

- Water-based composition No. 33. Latex and polymer modifier are added to the composition. Designed for hand or machine application. Often used for waterproofing structures in contact with the ground.

- "Eureka" number 41. It is made on the basis of bitumen using polymers and mineral fillers. Hot mastic is most often used for roof repairs. The insulating compound can also be used to treat pipelines and metal structures in direct contact with the ground.

- Hermobutyl mass No. 45. The butyl sealant is white or gray in color. It is used to seal panel seams and joints of metal prefabricated parts.

- Protective aluminum mastic No. 57. Possesses reflective properties. The main purpose is to protect roofs from solar radiation and the effects of atmospheric precipitation.

- Sealing mastic No. 71. Mass with a dry residue. Contains aromatic solvent. It adheres to concrete substrates and bituminous surfaces.

- AquaMast. Composition based on bitumen with the addition of crumb rubber. Designed for all types of roofing work.

- Non-hardening mastic. A homogeneous and viscous compound used for sealing and waterproofing exterior walls.

All mastics based on TechnoNICOL corporation bitumen are manufactured in accordance with GOST 30693-2000. The manufactured roofing materials have a certificate of conformity and a quality certificate confirming the high technical characteristics of construction products.

Consumption

TechnoNICOL bituminous mastics have an economical consumption.

Its final numbers will depend on many factors:

- from the manual or machine method of application (in the second case, the consumption will be minimal);

- from the material from which the base is made;

- from the type of construction activity.

For example, for gluing roll materials, the consumption of hot mastic will be approximately 0.9 kg per 1 m2 of waterproofing.

Cold mastics are not as economical in consumption (compared to hot ones). For gluing 1 m2 of coating, about 1 kg of the product will be required, and to create a waterproofing surface with a layer of 1 mm, up to about 3.5 kg of mass will be spent.

Subtleties of application

The technology of waterproofing the surface with hot and cold mastics has some differences. Before applying both compounds, it is necessary to prepare the surface to be treated. It is cleaned from various contaminants: debris, dust, plaque. Hot mastic must be heated to 170-190 degrees. The finished material should be applied with a brush or roller, 1-1.5 mm thick.

Before applying cold mastic, the previously prepared surface must be primed. Such measures are necessary to improve adhesion. After the work carried out, the mastic should be thoroughly mixed until a homogeneous mass is achieved.

Cold-used materials are applied in several layers (the thickness of each should not exceed 1.5 mm). Each subsequent waterproofing membrane should be applied only after the previous one has completely dried.

Storage and use tips

When working with bituminous mastics, it is necessary to comply with all safety requirements prescribed by the manufacturer of construction products. For example, when carrying out measures for waterproofing structures, you must follow the fire safety rules. When using mastic indoors, it is important to worry about creating effective ventilation in advance.

To perform work on waterproofing the surface with high quality, you need to heed the advice of experts:

- all work should be carried out only in clear weather at a temperature not lower than -5 degrees - for water-based mastics, and not lower than -20 - for hot materials;

- for quick and high-quality mixing of the composition, it is recommended to use a construction mixer or a drill with a special attachment;

- surfaces located vertically must be processed in several layers (in this case, the mass should be applied from the bottom up);

- at the end of the working process, all tools used are thoroughly washed with any inorganic solvent.

In order for the mastic to retain all the consumer properties declared by the manufacturer, you need to take care of its proper storage. It should be kept closed in a dry place, away from open flames and heat sources. Water emulsions must be protected from freezing. To do this, it should only be stored at positive temperatures. When freezing, the material will lose its performance.

For information on the features of TechnoNICOL bituminous mastics, see the next video.

The "peculiarities" of TechnoNikolevskoy mastic are that against the background of ALL instructions for use, ALL these FIVE manufacturers indicated on the bank did not deign to indicate HOW TO DILUTE it. Are they hiding something? And having bought a jar, it is IMPOSSIBLE to even mix (thoroughly) it (as they recommend). Only a HAMMER can drive a spatula into it !!!!

The comment was sent successfully.