Alkyd varnish: properties and scope

Alkyd varnish is often used for treating wooden surfaces outdoors and at home. There are several varieties of this material, so you should study in detail the properties and scope of each type.

What it is?

Alkyd varnish is a mixture containing various synthetic alkyd resins with organic solvents. The product has good adhesion and a high level of moisture resistance.

Alkyd varnishes are actively used for working with various types of surfaces.

- End parquet. Alkyds do not allow the ends to stick to each other, therefore surface stress is excluded;

- Parquet floors with "warm floor" system;

- Floating floors;

- Parquet made from delicate woods that are highly sensitive to the environment.

When this varnish hardens, it forms a transparent and fairly hard layer. Many people say that alkyd agents harden for a long time. However, manufacturers have developed products with special additives, with which they shorten the curing time. This means that the surface can be used after a short period of time.

After polymerization, a glossy or matt film forms on the alkyd varnish, depending on the selected product. The material that you will process with such a mixture will be provided with reliable protection against irritants of any type. It is quite simple to apply the alkyd mixture, since the product has a thick consistency, due to which the product spreads well over the floor and other treated surfaces, creating a dense film layer.

Advantages and disadvantages

The advantages of alkyds include the following properties:

- solutions are resistant to temperature changes, changes in humidity. Alkyd varnishes have no competitors in this area;

- increased level of vibration resistance;

- the composition has no adhesive properties. Therefore, floors treated with such varnish will not creak;

- high decorative qualities. The product is able to penetrate deeply into the wood, thereby highlighting the natural beauty of the product;

- convenient application due to its thick consistency;

- after polymerization, the varnish forms a matte or glossy film;

- optimal indicators of resistance in relation to loads of a mechanical nature;

- alkyd varnishes are resistant to contact with chemicals;

- no mold or mildew forms on the surface.

Among the shortcomings, users note the following qualities:

- the varnish dries for a long time. Polymerization takes more than a day. However, as previously described, some manufacturers add special hardeners that will shorten the setting time;

- until the surface is dry, the varnish emits an unpleasant odor which can be harmful if inhaled. In order not to harm your body, you must leave the windows open until the product hardens;

- alkyd products can wrinkle if you apply too much varnish to the surface. Therefore, you should follow the instructions for use;

- the service life of the surface is about 3 years.

Specifications

Almost every type of varnish goes through testing before it hits the counter. Each sample is kept under normal conditions for two weeks prior to testing.Testing consists in examining external characteristics using special devices.

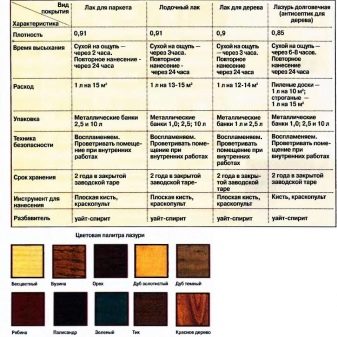

The device defines the following technical characteristics:

- the thickness of the varnish when applying two layers;

- the period during which the varnish completely hardens;

- resistance to mechanical stress;

- resistance to moisture;

- consequences from contact with detergents;

- term of use.

Only those mixtures that meet the stated requirements are allowed for sale.

According to the established standards, the composition of the alkyd varnish must have a colorless structure, which, after being placed on the surface, forms a matte or glossy layer.

Buyers get a reliable and quality product, which, after use, will noticeably transform the surface to be treated. To carry out internal work, you should rely on your personal requirements, which are necessary for the implementation of a specific goal.

Typically, alkyd varnishes are used on wood surfaces.

Alkyd urethane varnish can be divided into two main categories:

- yacht;

- parquet;

Yacht material is used for painting ships. According to statistics, this product is considered the most popular. Customers are attracted by the low cost of the product along with its increased resistance to wear and tear.

Remember that yacht varnish is not suitable for interior work indoors, as its composition has a high level of toxicity. When dry, it emits poisonous vapor, after polymerization - less hazardous volatile components. The service life of the material is about 5 years.

Parquet varnish is used for working with wooden floors. Both varnishes are suitable for all other wood surfaces. Yachting is often purchased to work with gazebos, verandas and other forms of architectural character.

Parquet lacquer is relevant for interior finishing activities. Besides floors, it does a good job with furniture, frames, railings and doors.

Alkyd varnishes for parquet are divided into several types.

- Water based solutions. This product is popular because it is odorless. The advantages include such properties as environmental safety and resistance to high temperatures. However, such products are distinguished by their high cost, which is not suitable for every buyer;

- Two-component. Such mixtures create a film on the parquet. They have a low cost and a pungent odor during drying. It is not possible to store the material in open containers for long, so you need to use up the varnish immediately;

- One-component varnishes. They can be stored for a long time in a closed container. Polyurethane mixtures are not afraid of contact with chemicals;

Also, such a varnish can be divided into several subtypes:

- matte;

- semi-matte;

- glossy;

- semi-glossy.

Matt products are optimal for surfaces that get dirty quickly during use, as the matte film is easy to clean.

Gloss reflects light well, therefore it is suitable for use in dark rooms.

PF-231

This varnish is considered a high quality alkyd-based product. It creates a gloss on the surface that is resistant to wear. The solution is transparent, has decorative and moisture resistant qualities. Such material is purchased for working with surfaces made of metal and wood, as well as for processing parquet indoors.

MCh-0163

Such a product belongs to the category of two-component varnishes, the composition of which consists of urea-formaldehyde and alkyd resins, acid hardeners.

If we compare MCH-0163 with the previous version, this type of varnish has improved characteristics:

- high level of water resistance;

- strength;

- resistance to the influence of abrasive substances.

The disadvantages of users include darkening on contact with sunlight, poor surface elasticity, strong odor and blistering during processing.

EP-2146

The brand is considered a one-component alkyd-epoxy compound that has improved characteristics. The improved element is epoxy resin. The product is characterized by increased hardness, resistance to abrasives and water.

The varnish is used for the treatment of parquet, wood surfaces, textured and decorative paper. It should be noted that there are no analogues of such a product abroad.

PF-283

Used for processing wood and metal surfaces. When applied, the solution forms a highly glossy layer that has good decorative qualities. PF-283 is a mixture containing alkyd resins, modified vegetable oils, fatty acids of vegetable oils, tall oils in organic solvents. Also in the composition of the components there is a desiccant. Apply the varnish with a brush or use an aerosol in a can for this purpose.

You can find out more about the varieties of alkyd varnish by watching the following video.

Selection Tips

When choosing an alkyd varnish, you should decide on some criteria:

- decide what kind of work you need varnish for: external or internal;

- there are varnishes for wood surfaces and for metal processing. Some varieties may work well for paint;

- decide what load will be carried out on the treated floor surface. If only two people live in the house, you can choose a water-based product. For the treatment of the corridor, a product with pigments is suitable. Such a material qualitatively protects the surface from the formation of dirt and dust;

- for the kitchen, you can purchase an anhydrous polyurethane mixture. The floor covering absorbs the product well, so no additional care is required;

- if you want to apply varnish on a surface where intense loads are present, you should purchase formulations in which water-repellent elements are present.

Many buyers choose tinted varnish to get the most decorative effects from the surface. To make the floor look spectacular, use a colorless compound as the first layer, which will help level the surface and smooth out all wood defects. To demonstrate the naturalness of the wood, apply the tinted solution first.

Consumption

Many people are interested in how much an alkyd varnish has. This indicator depends on the type of mixture and your talent. Experts advise to apply 2-3 layers of varnish. Each level should only be applied after the previous one has dried. Thus, it will take you at least 3 days to finish the surface.

The consumption of alkyd products is 50-75 grams per square meter. If you use more varnish than you should, the curing time will increase. You also run the risk of getting a less durable surface.

Before use, some brands should be diluted to a working consistency with xylene or solvent. You can mix one of these drugs with white spirit in a 1: 1 ratio.

Manufacturers

Several brands are in great demand among buyers:

- White house

- Parade

- Tikkurila

Alkyd-urethane mixtures from Parade managed to win a large audience, since this manufacturer sells varnishes with increased elasticity. Buyers leave reviews in which they report that the film that forms after applying the product does not crack or deteriorate for a long time. Alkyd products are able to emphasize the naturalness of the wood material and make the floor more effective. Parade offers its customers mixtures for outdoor and indoor use.

White house conquered buyers with affordable prices and a faint smell.The manufacturer produces high-quality varnishes, which are distinguished by high wear protection, fast polymerization and a decorative component. The varnish is able to preserve the natural shade of the wood. Just like Parade, the manufacturer produces products for outdoor and home surfaces.

Tikkurila is considered a proven manufacturer of many building materials. The brand has won the respect of customers and is known as a manufacturer of reliable and high-quality products. Tikkurila yacht varnish receives good reviews, which is distinguished by fast polymerization, excellent spreadability. The low price helps this brand to become a leader among the manufacturers of alkyd varnishes.

The comment was sent successfully.