Distance between floor joists

Lags for the floor are called crossbeams, most often representing pieces of timber fixed on the interfloor overlap. Their cross section, thickness is at least 3 times greater than the same parameters of the flooring boards.

For example, a 15x3.5 cm board is placed perpendicularly on a 12x12 cm bar. In the article we will consider what the distance between the floor lags should be.

What does the step depend on?

The distance between the logs for floor boards depends on the load on the assembled floor, the own weight of the entire timber and the dimensions of the room, as well as the section of both the board and the timber. Too small a step, although it will give strength, will result in excessive weight of the structure or building, it will be necessary to recalculate the plan starting from the foundation before starting construction. Too large a step - the boards will bend under the weight of people, furniture and equipment, in the worst case, the floor can crack and fall either onto the floor below, or come into contact with the subfloor (foundation) of the building, while violating the thermal and vapor insulation of the latter. In any case, if the boards are damaged, people and objects fall in the room, repairs will be required, including strengthening the "lag" component.

Laying additional lags with the possible replacement of existing damaged ones is inevitable. Similarly, the boards themselves will be replaced - those of them that have time to deform.

Calculation features

Without going into formulas, laboratory recalculations and experiments, an experienced installer, carpenter, master-stacker is immediately guided by the laws of physics and the estimate developed over the years of successful activity. After all, he is faced with the task of making sure that the house when "legalizing" (if it is a country house, without registration of the owner) does not have any claims from local representatives of government agencies and structures, which will certainly conduct a full-fledged fire-technical examination and cadastral legal support, so that issue a conclusion on the suitability of the house for year-round living.

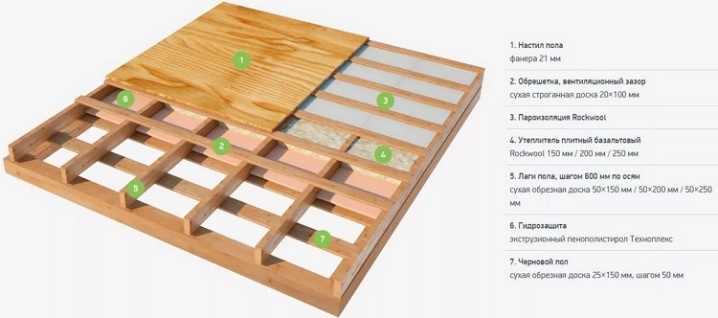

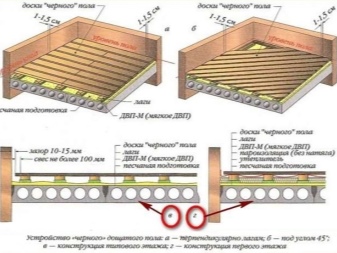

Let us explain this with a specific example. So, the house is built or reconstructed (the plan is changed). The owner can go in two ways: either "insulate" with tiles on expanded clay concrete, or build full-fledged wooden floors. In the second case, for example, such a net will help: boards with a section of 4 by 16 cm, logs with a section of 12 by 12 cm.For the floor of the first floor, as well as for basements, where the supporting subfloor (foundation) is already there, the thickness of the lags is not plays a prominent role. The same is true for reinforced concrete floors. It is possible, in general, to do without lags, if the task is not to lay insulation between pieces of wood and reinforced concrete, for example, when a heating cable for underfloor heating is embedded in the screed.

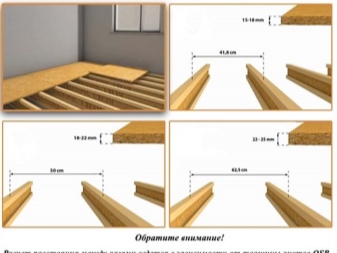

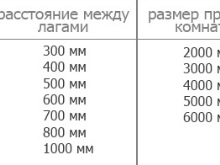

There is a universal recommendation that cannot be violated: a board height of 2 cm will require a distance of 30 cm between the beams. For 2.5 cm of the same height, the flight distance will increase to 4 dm; for 3 cm - 5 dm of span, for 4 cm 6 dm is taken. For a 5 cm distance - already 1 m. Large distances between beams in private-suburban construction are not practiced. The calculation was made for empty rooms, but under heavy load these parameters are significantly recalculated. The goal is a 3-4-fold safety margin, only such a rule will ensure the reliability and durability of the floors.

For the arrangement of floors, a log was often used earlier. It must be turned, rounded and calibrated: constant diameter along the entire length, smoothness, excluding board deviations.Strict requirements for the logs exclude vibrations even of the grooved floorboard.

Today, the log is actively squeezed out of circulation - timber is more often used for logs.

A modern floor meets several requirements at once:

- perfectly horizontal flooring;

- additional protection against extraneous sounds;

- ventilation (microcirculation) under the plank floor;

- the purpose of the space under the floor for electrical connections, water supply;

- additional protection against cold in winter and heat in summer;

- the speed of dismantling old and installing new elements when they are deformed.

Spruce, pine or fir will serve as the material of the bar. Flooring in a bathhouse will require hardwood - it is better able to withstand waterlogging and the associated gradual decay (decay). Larch, although it costs much more, will last longer. Logs are material that is undemanding to high quality and perfect appearance: they are hidden under the flooring after the installation of the flooring. The section of timber timber is chosen square or rectangular: in the latter version, the thickness of the beam is 1.5 times higher than its width. The bar does not "lie", but stands on the edge.

For beams, building materials of the 2nd and 3rd grades are taken, the water content by weight in the wood should not be more than 18-20%. Such wood belongs to the harvesting of natural moisture. A cross-sectional beam is necessarily taken rectangular, and not square, when it is placed between floors without a reinforced concrete supporting ceiling. Such a ratio in the cross-section of the timber allows the owner and residents of the building to be as safe as possible, having achieved a high resistance to possible deflection from an increased load.

If you try to imagine more clearly how the decision made will be embodied in practice, it turns out that for a living room with heavy furniture and a rich interior, the span between the logs, calculated according to the previous scheme, should be 5-10 cm less than in the bedroom, where from heavy items only a bedroom set and a wardrobe. For the corridor, this indicator is less - by the same amount than for the bedroom interior.

Some owners of country houses install a wardrobe and poufs in the corridor, but this does not mean that the rest of the load on the remaining occupied area is the same: as a rule, little additional pieces of furniture are kept in the corridor, since the corridor is a non-residential area. Consequently, the floor in the corridor does not require capital reinforcement, as in living rooms.

The span of the laid beams should never be underestimated. The cross-section of the timber, on the contrary, is not fully taken into account. Nevertheless, the strength characteristics of the floor are of decisive importance.

If all the other values of the characteristics (their sample) are strictly observed, then this violation will not significantly affect the durability of the floor.

Do not skimp on the section of the timber - its insufficient sampling will seriously reduce the life of the floor. Experienced installers take the material with a margin of safety - it is better to overpay a not so large amount once and make a "floor forever" than to change it, spending more money in the end. When calculating the thickness (height) of the boards and beams, the thickness of the insulation layer is also taken into account.

Let's give one more example. A two-meter distance between the lags will require at least a beam of 11x6 cm. A three-meter span will require 15x8 cm, a four-meter one - 18x10 cm. »Spans are not needed. In addition, there is no need to use different spans for rooms in the same country house: the floor height will differ, which will create additional inconveniences.

How to mount correctly?

The specialist uses construction script calculators, or, knowing SNiP, calculates all the necessary parameters for the flooring and beams on his own. A beginner usually takes advantage of security considerations: he can easily overestimate the thickness of the boards by a factor of 1.5 by decreasing the value of the span between the beams. By increasing the cost of installing the floor, the consumer will significantly save on repair and maintenance: this "investment" will be beneficial here. This approach is often adhered to by people who, in their old age, do not need hasty repair sessions, they want to live calmly and measuredly.

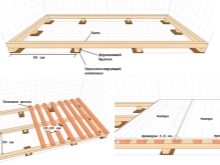

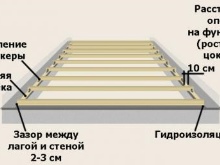

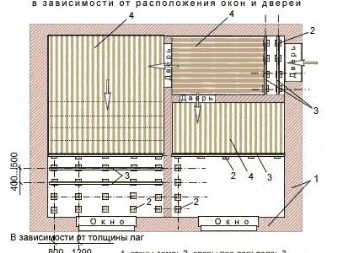

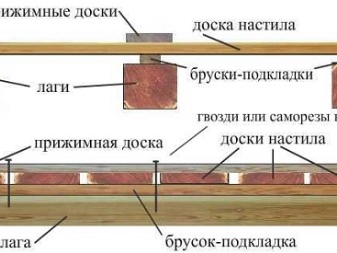

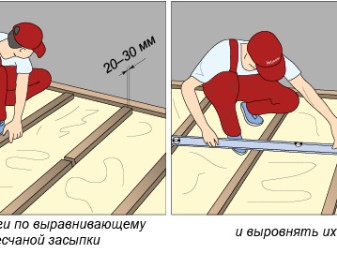

Before fixing the beams, they are set on the level gauge. Then, putting the pieces of timber "on one side", while the ones closest to the walls are laid at a distance of 10-30 cm. Further, dividing the remaining distance between them by the selected span, their number is calculated. If the master did not fit into this size a little, and instead of the last two spans, say, 50 cm, it turned out to be one in 90, then it is better not to save money and put a piece of timber that “did not fit” into this gap approximately in the middle of it.

As a result, the last two beams fall into approximately the same spans compared to the rest of the gaps. If you are faced with such a non-standard calculation plan in your opinion, then before fixing the lags, move them proportionally, the uniformity of the arrangement is no less important: the centers of mass of the structure will not shift.

An example of a calculation is concretized as follows.

- The length of the room is 9 m.

- The thickness of the board is 2.5 cm.

- The distance between the lags is 22.35 cm.

This distance is taken between the extreme edges of adjacent beams, and not between their midpoints. For a board, for example, under 40 mm, an appropriate recalculation is made depending on the other characteristics of the room finished in the future. The minimum allowable distance between the lags is not defined - decreasing the value of this parameter is generally not critical. A thicker board is suitable for a garage.

However, be sure that you cannot drive, put the car on a wooden floor: it is mounted at a level several centimeters lower than the lower edges and edges of the car's opening doors. This is necessary to exclude an accidental collision of the car's wheels on such a floor.

But laying a wooden floor, for example, on a balcony, obeys general rules that are fair for rooms - it is only important that the balcony slab itself and the support under it withstand the load (the maximum limit is considered according to SNiP standards for low and multi-storey buildings).

It is not recommended to use chipboard for flooring - natural wood is much stronger than glued and compressed sawdust. In addition, the manufacturers' savings on the quality of the glue have completely transferred chipboard and OSB into a low-strength, unreliable building material. It is used only in those places where there is no additional load (walls and partitions, ceiling). However, for beams on foundations or reinforced concrete floors, glued beams can be used. The use of polycarbonate, in general, is not justified for floors: its strength is too low, and it is noticeably more expensive. Polycarbonate is suitable only for insulation (for example, cellular), or, say, for the roofs of gazebos, but not for the floor.

Minor calculation errors will not reduce the strength of the floor. If you do not want to recount again, then purchase a bar with a margin. Being installed more “often”, it will only create the basis for additional reliability, but the installed floor with timely staining, sanding from old paint layers and additional priming before subsequent painting sessions will serve you for a long time - all your life.

The comment was sent successfully.