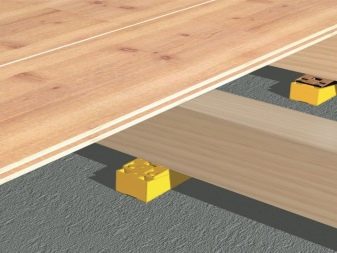

Underlays for joists for leveling the floor

Pads for alignment logs can be very diverse. Among them there are rubber and plastic, adjusting models for floor joists, wooden and brick supports. Some of them are easy to do by hand.

Appointment

There are a number of good reasons that motivate you to place various items under the logs. It's not just subjective comfort. Other factors are:

-

insufficient safety of uneven surfaces;

-

uniformity of load distribution (and wear from it);

-

prevention of contact with moisture;

-

improved ventilation;

-

raising the structure (it should only be noted that not all materials cope equally well with each of these functions).

Overview of rubber pads

This solution does a good job of aligning. But it is also recommended for organizing full-fledged slopes. Both options are suitable if you want to evenly distribute the weight load on the log. Rubber well prevents contact of a wooden log with water. It is also capable of protecting WPC structures, aluminum and iron products.

Extraneous noise is damped inside the rubber mass. She herself does not have any unpleasant odors. Ultraviolet light and precipitation do not harm it. Rubber successfully competes with plastic models. Such elements will help smooth out the unevenness of the bases and even raise the boards by about 1-1.5 cm as needed. Adjusting pads for logs can be applied both indoors and outdoors, in the temperature range from –40 to +110 degrees; under normal conditions of use, the service life is theoretically unlimited.

The main properties of Gardeck linings:

-

size 8x6x0.6 cm;

-

permissible temperature up to 100 degrees;

-

density 1000 kg per 1 cu. m;

-

density on the Shore scale 60 points;

-

tear resistance up to 1000 kPa.

Adjustable supports can be made differently. They are made according to the scheme typical for screw jacks. The height is set by turning the screw. Installation error - 1 mm. As soon as the required indicator is reached, the product must be fixed with a key.

Strong metal legs can withstand open flames and withstand significant mechanical stress... And now, screw supports are also produced from durable plastic grades. Thanks to them, you can just as accurately set the height of the log and the front floor covering. Most often, polypropylene is taken as a basis.

The delivery set includes a variety of parts, including a slope correction block; the actual rubber cushion pads can also be included in some kits, although sometimes they have to be purchased additionally.

On top of the adjustable supports, you can safely put not only classic boards, but also:

-

decking;

-

plywood sheets;

-

wood composite;

-

Fiberboard;

-

Chipboard;

-

tile.

The dry prefabricated screed technique is applicable in any premises, regardless of their purpose. It has a very low weight, which is very useful for overhaul in old worn out houses. Rubber and plastic pads, in combination with or without adjusting elements, eliminate the long drying times typical of concrete. Such structures will provide good ventilation of the space under the floor. Numerous communications can be laid there, and if there is a desire, even equipping a multi-level floor is also good.

Homemade lining options

But there is no need to buy special products for wooden logs to level the floor, because in many cases they are made by hand. When mounted on posts, the existing set of rules in construction directly requires fixing the lags to the supports. This method of alignment is achieved by pulling through the support with dowels or self-tapping screws directly to the base. Pads should be used wherever they are needed. The height (thickness) of each of them is chosen so as to put from 2 to 4 pieces under the lag.

It should be understood that wooden supports (including split plywood) align the structure very roughly. More precisely, this can be done due to the folded roofing material.

The use of OSB-plates is possible, but this technique is still poorly worked out, so you will have to follow it at your own peril and risk. In some cases, the logs are placed on brick posts. Such designs allow you to lay out the floor evenly and correctly.

Usually they are made with a section of 1 brick. A reinforced concrete pad on M500 cement is preliminarily formed. A bracket is placed in the middle, the upper part of which has a thread. A steel plate is welded to the base of the bracket, and all brackets are centered, bringing them to zero horizontally. The support is ready when a moisture-resistant brick lining from 4 sides is added to such a structure.

The comment was sent successfully.