Recommendations for the selection and installation of foundation bolts

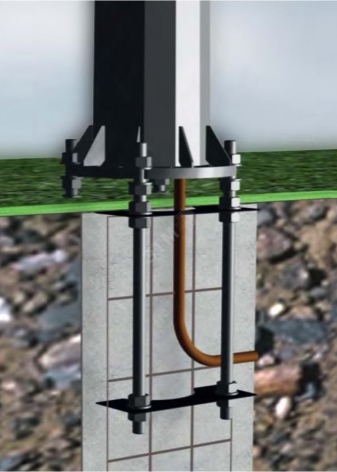

In the process of construction or major repairs, the strength and stability of the structure under construction are fundamental. Thanks to the use of foundation bolts, it is possible to firmly fix the supporting columns in the building, as well as to securely fix the necessary equipment. The principle of operation of such anchor fasteners is based on the "anchor".

Despite the fact that each type of foundation is a solid and reliable system, it is recommended to connect it to the walls using specially designed fasteners. These are foundation bolts. They are inserted into the structure even before the concrete solution is poured or after it. In this article, we will tell you in detail about the nuances of performing their installation.

Peculiarities

In construction, for fastening reinforced concrete or steel structures to the base, special fasteners are used - anchor bolts. Their use makes it possible to significantly increase the stability of the building structure itself. But also foundation bolts allow you to reliably fasten the supporting columns and other necessary elements of the object being built. Their principle of operation is based on the type of anchor mounted in the structure of the building material itself, firmly attached to it. It is very important to choose the right anchoring elements of fasteners correctly.

The production of these fasteners is carried out according to a special document - this is GOST 24379.1-80 known to all professional builders. By cutting into the base of the building, the anchor bolts create a strong connection that can withstand heavy loads (dynamic and static). But this is subject to the construction technology. To ensure all this, only high quality materials are used in the manufacture. From above, the bolts are additionally covered with a layer of zinc, which protects them from the influence of the environment.

Views

Anchoring is used for the construction of various types of foundations. Therefore, such products can be different: size, steel grade, weight and length. Today in the domestic market in this segment these products are presented from 15 centimeters to 5 meters.

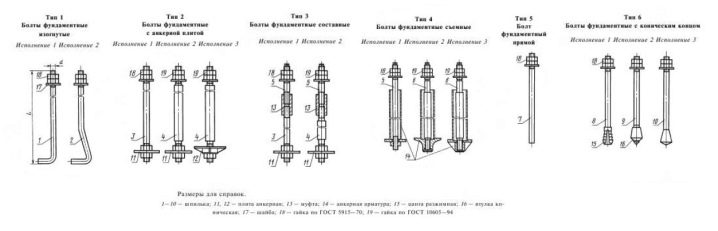

As for the types of foundation bolts, they are classified into several types.

- Curved. They are made in the form of a metal rod, one end of which has a curved shape. Outwardly, it looks like a hook. Designed for installation in a reinforced concrete foundation and for joining large equipment.

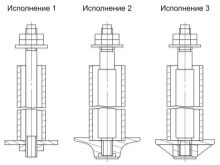

- Composite. Their length can be up to several meters. The structure consists of elements such as a threaded rod, anchor plate, a sleeve, a nut and a metal pin. These fasteners are used when it becomes necessary to tie two structural elements. One end is in concrete, and the other is screwed into the sleeve. The diameter of the compound bolt is different (M16, M20, M24, M28, M30, M36 and others). You can choose it from a special table.

- Straight. The bolt design is similar to an ordinary metal pin. There is a thread at one end. Its length can be 140 centimeters. A distinctive feature here is the fact that the straight bolt can be mounted in a ready-made foundation. For their reliable fixing, a special adhesive composition or cement is used.

- With special anchor plate. The manufacture of such fasteners is carried out based on the current GOST 24379.1-80.One part of the bolt is fixed even before the foundation itself is substantiated. This is done by welding or threaded connection. The peculiarity of such fasteners is the size. It can go up to 5 meters.

- Detachable type. There is a special anchor system here. With its help, a reliable fixation is carried out in a reinforced concrete, brick or stone foundation. Thanks to this fastener, it is possible to install various engineering structures. The lower bolt race is laid in the foundation, and the upper threaded stud is mounted after concreting.

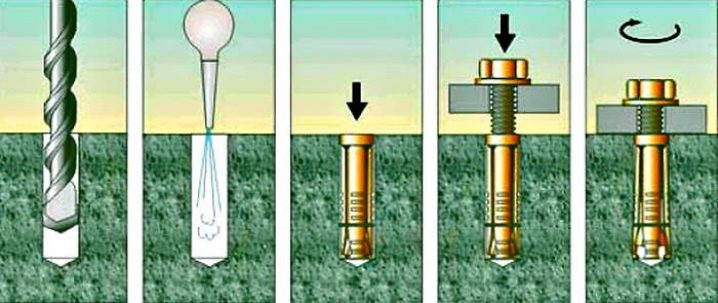

- With a tapered tip. The collet bolt is mounted directly into the foundation. The area of purpose is to fasten boilers to the wall, furniture and much more. Thanks to a special collet of the expanding type, wedged when twisting, a strong and reliable fixation is ensured.

Installation

Before proceeding with the installation of this type of fastening, it is necessary to calculate the necessary bolts in accordance with the project documentation. This is done to determine their performance characteristics. It is worth considering the distance from the edge of the foundation, as well as the depth of the hole. Anchor bolts are held in place due to features such as adhesion, stop and friction. As for the stop, this is the load that the fastener takes on and compensates due to its design characteristics. The load is provided by friction. But gluing is the compensation of these loads due to "shear stresses".

But it is also worth focusing on the fact that the size of the anchor, together with the embedment depth, should not be greater than the height of the foundation itself. This is very important, otherwise at the moment of tightening the bolt itself, a violation of fixation will occur. You will not achieve the required reliability of such an attachment. The connection to the hob must be firm and durable.

Before installing the bolt in the foundation, it must be visually inspected for possible defects in the structure.

Installing anchors is not a complicated procedure. It can be done independently without involving a team of professionals.

However, to do this, you need to adhere to a number of basic rules.

- Thoroughly study the plan of the construction site, and determine the exact places for the installation of anchor bolts.

- Control the immersion depth of this anchorage into the already formed foundation. It should not be larger than its thickness.

- Be sure to consider the distance between adjacent fasteners. The calculation is quite simple: these are two values of the embedment depth itself.

- The foundation bolts must be perfectly vertical.

- Formation of a block of this type of attachment. After the concrete is completely dry, you need to fasten all the ends of the bolts with an iron plate or board with pre-drilled holes. Thanks to this, the reliability of the entire structure will be high.

- If you fasten the anchor fasteners even before the foundation is poured, then it is also worth calculating in advance their most accurate location according to the building design.

Advice

If you doubt your abilities, then it is best to entrust the installation of anchor bolts to real professionals in their field. This will not only save your efforts, nerves, time, but also money for the repair of the entire structure.

If you want to choose the highest quality anchorage, then for this you should take into account the following main characteristics:

- the load that the bolt can withstand;

- required length;

- type of fastening, based on the design features of the foundation;

- type, strength and the structure of the base itself;

- distance between holes;

- bulkiness and volume of the structure that you need to hang.

If you have a removable structure, then the anchoring reinforcement is mounted even before concreting. The studs are installed upon completion of the foundation pouring.As for the dimensions of this fastener, it is selected based on the weight and dimensions of the structure itself. The larger it is, the longer the anchor bolt must be. Its size can always be determined based on the marking. The first number here shows the outer diameter, the second the inner diameter, and the third corresponds to the total length.

As for the installation of anchor bolts, it is the same everywhere. An exception to this is push-in fasteners. Here you do not need to turn the nut, but hammer the anchor with a hammer.

Recommendations for the selection and installation of fundamental bolts in the next video.

The comment was sent successfully.