How to select and install FBS foundation blocks?

Foundation blocks allow you to build strong and durable foundations for various structures. They stand out favorably against the background of monolithic structures with their practicality and speed of arrangement. Consider the positive and negative sides of the foundation blocks, as well as the independent installation of this structure.

Peculiarities

FBS blocks are used for the construction of foundations and walls of basements, as well as for retaining structures (overpasses, bridges, ramps). In order for the foundation blocks to have a high strength index and serve for a long time, they must have specific technical characteristics.

The density of the building material must be at least 1800 kg / cu. m, and inside the material should not contain air voids. The foundation blocks inside can be either hardened or non-hardened. The latter variation is quite common. Reinforced products are made to order.

FBS function as a permanent formwork, reinforcement is installed in the voids and filled with concrete mortar. They have cutouts for the practicality of installing various communications. In accordance with GOST, all types of such blocks are used for the construction of walls, subfields, and solid structures are used for the construction of the foundation.

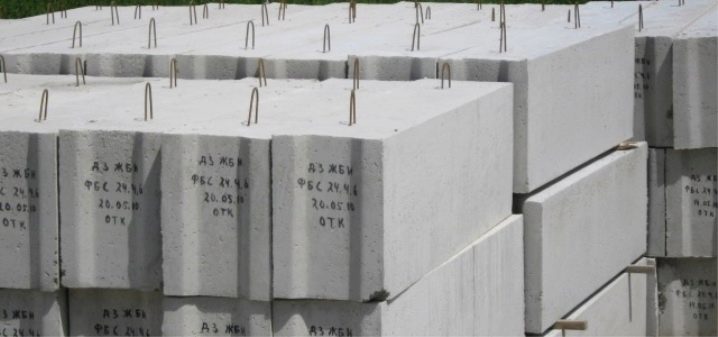

During the production process, the blocks are compacted on vibrating tables; for casting, specialized molds are used, which make it possible to accurately observe the geometry of the structure. Materials with disturbed geometry are unable to form dense masonry, and too large seams in the future will be a source of moisture penetration into the structure. For accelerated hardening and strength gain, concrete is steamed. With this manufacturing process, concrete is able to achieve 70% stability in 24 hours.

In terms of rigidity and strength, foundation block structures are inferior to monolithic foundations, but they are cheaper and more practical. Foundation blocks are best for soils with a high sand content.

In places with crumbly and soft soil, it is better to abandon the construction of such a foundation, because the structure can sag, which will lead to further destruction of the building.

Block structures are resistant to the influence of soil heaving forces. In environments where concrete belt systems can burst, the blocks will only bend. This quality of the prefabricated foundation is ensured due to the non-monolithic structure.

pros

Foundation construction using FBS is in great demand among consumers due to the existing advantages that this building material has.

- High index of frost resistance. These building materials can be installed at any temperature conditions, because the product contains special frost-resistant additives. The structure of the reinforced concrete structure remains unchanged under the influence of low degrees.

- High resistance to aggressive environments.

- Acceptable cost of products.

- Wide range of block sizes. This makes it possible to carry out the construction of very small-sized premises, as well as large-sized special production facilities.

Minuses

Arrangement of a block foundation requires specialized lifting equipment, which means that you will have to make certain financial costs for renting special equipment.

The block foundation is strong and durable, but its construction is associated with some inconveniences.

- Material costs for the rental of lifting equipment.

- When the blocks are installed one-on-one, scars are formed in the structure, which require additional waterproofing and thermal insulation. Otherwise, moisture will penetrate into the room, and also through them all the thermal energy will go outside. In the future, such factors will lead to the destruction of the structure.

Views

GOST, which establishes the rules for the manufacture of FBS, provides for products of the following dimensions:

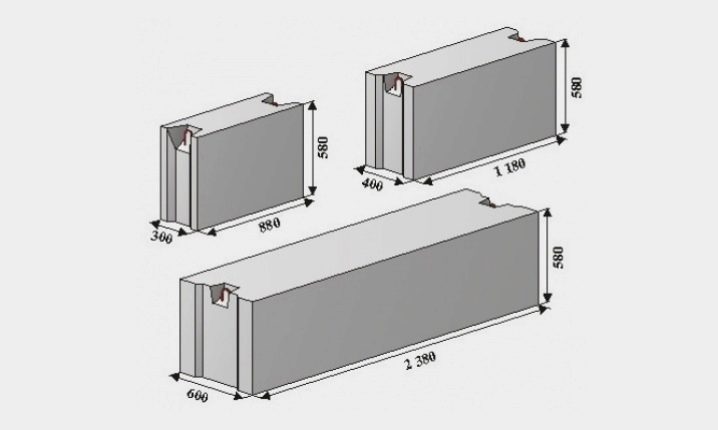

- length - 2380,1180, 880 mm (additional);

- width - 300, 400, 500, 600 mm;

- height - 280, 580 mm.

For the construction of basement and underground walls, foundation blocks are made of 3 types.

- FBS. The marking denotes solid building materials. The strength indicators of this product are higher than those of other varieties. Only this type can be used to build a foundation for a house.

- FBV. Such products differ from the previous type in that they have a longitudinal cutout, which is intended for laying utility lines.

- FBP Are hollow building materials made of concrete. Lightweight block products have square voids open downward.

There are also small-sized structures, such as 600x600x600 mm and 400 mm in size. Each structure is a rectangular parallelepiped with grooves at the ends for tight laying, filled with a special mixture during the construction of the foundation or wall, and construction slings, for which they are hooked up for transposition.

FBS structures are made of silicate or expanded clay concrete. The strength group of concrete should be:

- not less than 7, 5 for concrete marked M100;

- not less than B 12, 5 for concrete marked M150;

- for heavy concrete - from B 3, 5 (M50) to B15 (M200).

The frost resistance of the foundation blocks must be at least 50 freeze-thaw cycles, and the water resistance - W2.

In the designation of the species, its dimensions are marked in decimetres, rounded up. The definition also specifies the concrete model:

- T - heavy;

- P - on cellular fillers;

- C - silicate.

Consider an example, FBS -24-4-6 t is a concrete block with dimensions of 2380x400x580 mm, which consists of weighty concrete.

The weight of the blocks is 260 kg and more, therefore, specialized lifting equipment will be required for the construction of the foundation. For the construction of living quarters, blocks are mainly used, the thickness of which is 60 cm. The most popular block mass is 1960 kg.

In terms of magnitude, the deviation of the parameters should be no more than 13 mm, in height and width 8 mm, in the parameter of the cutout 5 mm.

Device

2 types of frames can be built from fundamental block products:

- tape;

- columnar.

The columnar structure is ideal for the construction of small structures on heaving, sandy soils, as well as on soils with a high groundwater index. Tape prefabricated frame is suitable for various stone structures in one row.

Both types of bases are laid according to the general technology for blocks. Block products are laid in the manner of brick laying (one-on-one) using cement mortar. In this case, it is necessary to observe that the cement mass contains a reasonable amount of liquid. Too much water will destroy the entire structure.

To increase the strength of the foundation, reinforcement is laid between the walls of horizontal and vertical rows of block products. As a result, after pouring the cement mixture and laying the next row of blocks, the foundation will have the strength of a monolithic foundation.

If the building plan includes an underground garage, basement or basement, then a foundation pit will need to be made in the ground, in which the foundation will be arranged.Concrete slabs are installed as a floor for the basement, or a monolithic screed is poured.

Installation

Step-by-step instructions for self-installation of block products include:

- preparatory work;

- excavation;

- arrangement of the sole;

- formwork installation and reinforcement;

- filling the pillow;

- laying of blocks;

- waterproofing;

- installation of a reinforced belt.

Preparatory work

It should be noted that the frame made of block products, in contrast to monolithic structures, is being erected in a fairly short time. And after installing it, you can proceed to building the walls. The most important condition for this is the correct calculation of the parameters of the foundation tape.

- The width of the future foundation should be greater than the design thickness of the walls of the building.

- Block products should freely pass into the prepared ditch, but at the same time there should be free space for builders to work.

- The depth of the trench under the perimeter of the base is calculated depending on the total weight of the future building, on the level of soil freezing, as well as on the characteristics of the soil.

Before proceeding with the installation, it is necessary to develop a diagram of the future foundation. For such a task, you need to draw the layout of block products. Thus, it becomes possible to understand the order of installation of materials and their bandaging.

Often, the width of the initial row of the block base is kept at the level of 40 cm.For the next two rows, this coefficient decreases to 30 centimeters. Knowing the necessary design parameters and the number of fundamental blocks, you can go to a hardware store to purchase building materials.

Excavation

The first step is to examine the building site. Plan where the special equipment will be located. And you also need to take care of the fact that at the construction site it can interfere with the work, the interference is eliminated.

- The corners of the future structure are determined, into which the stakes are inserted. A rope or rope is pulled between them, and then intermediate special marking elements are installed on the sections of the future structure of the inner and outer walls.

- Digging of the foundation pit is in progress. According to the rules, the depth of the pit should be equal to the depth of freezing of the soil with the addition of 20-25 centimeters. But in certain areas, the depth of freezing of the soil can be about 2 meters, the cost of such an arrangement will be irrational. Therefore, the average depth was taken as a value of 80-100 cm.

Arrangement of a pillow

There are 2 variations of the block base arrangement: on a sand cushion or on a concrete base. The second variation is suitable for unstable soils, but concrete pouring requires additional costs and forces. Before the process of arranging the pillow, the installation procedure for both options is the same. The procedure for building a foundation on a concrete base begins with the installation of formwork and reinforcement.

Crushed stone of 20-40 fractions, sand, fittings are prepared in advance. Then the following stages of work are performed:

- the walls and bottom of the pit are leveled;

- the bottom of the pit is covered with a layer of sand for 10-25 centimeters, watered with water and carefully compacted;

- the sand pillow is covered with a layer of gravel (10 cm) and compacted.

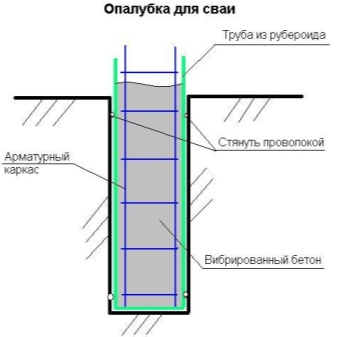

Formwork installation and reinforcement

For assembling the formwork, an edged board is suitable, the thickness of which should be 2.5 cm. The formwork boards are fastened with a suitable method. Mostly self-tapping screws are used for this purpose. The formwork is installed along the walls of the pit; such an installation must be checked with a building level.

For the reinforcement of the structure, metal rods with a diameter of 1.2-1.4 cm are used. They are tied into a mesh with cells of 10x10 centimeters by means of a flexible wire. Basically, the reinforcement is carried out in 2 layers, while the lower and upper nets are laid at the same distance from the crushed stone and subsequent pouring.To fix the grids, perpendicular reinforcement bars are pre-driven into the base.

If you are planning to build a large and heavy building, then the number of reinforced layers must be increased.

Pouring pillow

The entire structure is poured with concrete. The solution must be poured slowly in an even layer. The filling is pierced in several areas with fittings, this is necessary to remove excess air. The surface of the pillow is leveled.

After completing all procedures, the structure is left for 3-4 weeks in order for it to gain sufficient strength. On hot days, the concrete is moistened with water from time to time so that it does not crack.

Block masonry

To lay the foundation blocks, a crane is required to lift the massive structure. You and your assistant will need to correct block products and install them in designated places. For installation, you will need concrete marking M100. On average, the installation of 1 block will require 10-15 liters of concrete mixture.

Initially, the blocks are installed at the corners, for better orientation, a rope is pulled between the products, and the spans of the FBS are alternately filled in level. Subsequent block rows are laid on the mortar in the opposite direction.

Waterproofing

To perform waterproofing, it is best to use liquid mastic, which is carefully applied to the inner and outer walls of the foundation. In areas with heavy rainfall, experts recommend installing an additional layer of roofing material.

Installation of a reinforced belt

To eliminate the risk of destruction of the entire structure in the future, it must be strengthened. Often, for the strength of the base structure, a reinforced concrete belt is cast along the surface row, the thickness of which is 20-30 centimeters. For hardening, reinforcement (10 mm) is used. In the future, floor slabs will be installed on this belt.

Experienced craftsmen may dispute the need for a reinforced belt, because they believe that the slabs sufficiently distribute the loads, it is only necessary to install them correctly. But, according to the reviews of specialists already working with this design, it is better not to ignore the installation of an armored belt.

The design is performed in this way:

- formwork is mounted along the contour of the fundamental walls;

- a reinforcing mesh is placed in the formwork;

- concrete solution is poured.

At this stage, the installation of the foundation from block products is completed. The execution technology is laborious, but uncomplicated, you can build it with your own hands, even without some experience. By doing everything according to the instructions, you will build a safe and solid foundation that will serve a long operational life.

Advice

Consider the recommendations of specialists for laying fundamental blocks.

- Do not ignore the implementation of waterproofing, because it protects the structure from precipitation.

- For thermal insulation of the structure, it is better to use polystyrene or expanded polystyrene, which is mounted on the outside and inside of the room.

- If the size of the concreted blocks does not correspond to the perimeter of the base, voids will form between the block products. To fill them, use monolithic insert elements or specialized additional blocks. It is important that these aggregates have the same strength as the fundamental block materials.

- In the process of mounting the foundation, it is necessary to leave a technological hole through which communication elements will be held in the future.

- Instead of a cement mixture, you can use a specialized adhesive mortar.

- When building a strip foundation, you need to leave holes for ventilation.

- After the completion of the installation work, for one hundred percent setting of the materials, you need to wait about 30 days.

- After preparing the cement mass, it is forbidden to add water to it, as this will lead to a loss of binding qualities.

- It is best to build a foundation from blocks in the summer. This will help to avoid some difficulties with the geometric accuracy of digging the foundation pit. After the rain, you need to wait until the soil has completely dried, after which it is allowed to proceed with the installation.

- If the concrete has already been poured and it has started to rain, the entire structure must be covered with plastic wrap. Otherwise, the concrete will crack.

For information on how to select and install FBS foundation blocks, see the next video.

The comment was sent successfully.