What is a grillage and how to use it?

Knowing what it is - a grillage, and how to use it, is useful to everyone who decides to build a house. First, you need to answer the question of why grillage foundations are needed in construction in general. Then it will already be possible to deal with reinforcement, the features of monolithic grillages and their other types.

What it is?

Inexperienced builders and private developers do not always understand what a grillage is, and why this element is needed in construction. Meanwhile, everything is pretty simple. This design provides special rigidity and durability.... The load from everything that is above will be distributed as fully as possible. Purposes of using grillages:

- maintaining a fixed position of the supports;

- uniformity of load distribution;

- preparation of a reliable support system, along which walls and partitions can already be built without unnecessary hesitation.

The grillage structure is practically universal... She confidently keeps the basement floor in one-story and two-story houses. And it can also be used under a high-height fence made of heavy bricks. Such elements are used in construction on various soils. They help out even with pronounced instability of the base.

Almost always, when it comes to construction on problem ground, professionals first consider the possibility of using a grillage. Only if this is impossible or impractical, they move on to other solutions. With this type of work, complex manipulations with the ground will not be required. It will be possible to almost ignore the depth of the water.

However, it is rather difficult to equip a basement with a grillage, and the installation itself will require the use of special equipment.

Views

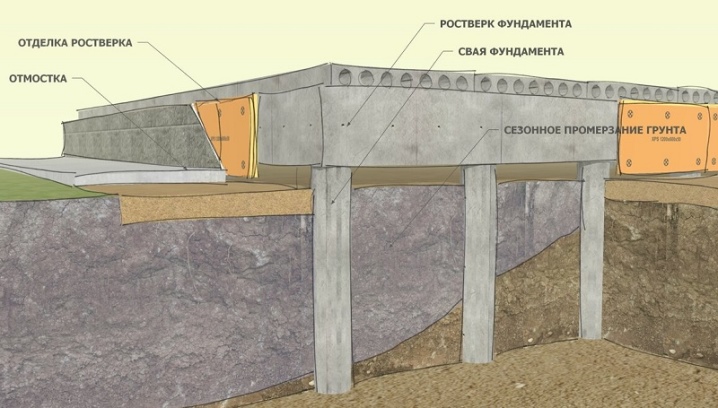

By location

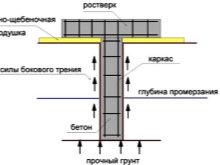

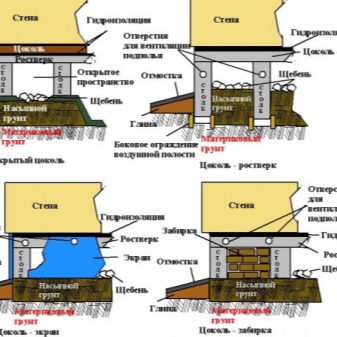

A tall, aka hanging grillage is not the only possible option. There are still increased and deepened types of performance. A structure is called high, the height of the lower plane of which is 10 cm or more higher than the planning blind area of the soil. It is this performance that experts consider the most stable in terms of functionality. Everything will remain stable, even if the freezing or heaving soil begins to deform. If you do not resort to the gap, then the grillage can be seriously deformed itself. Sometimes it comes to the point that it starts to pull out piles.

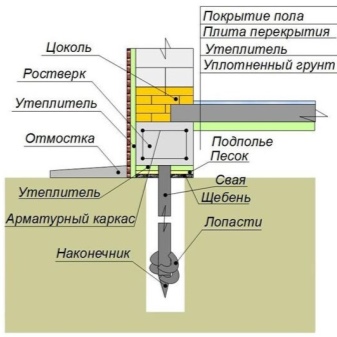

But when everything is done correctly, a ventilated area will be created under the floor, which will reduce humidity and provide coolness even on a hot summer day. However, this very circumstance - the leakage of the gap between the soil and the overlap - can be considered a disadvantage. Unlimited air movement carries away a lot of heat. Therefore, you have to deal with insulation or equip the house with shields that are lowered at the right time. Finally, a high-type grillage does not allow equipping a full-fledged basement.

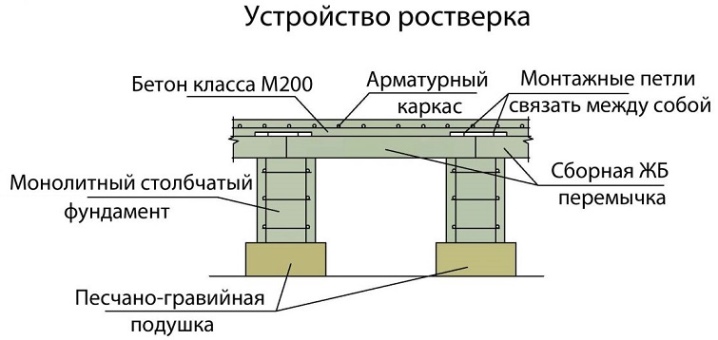

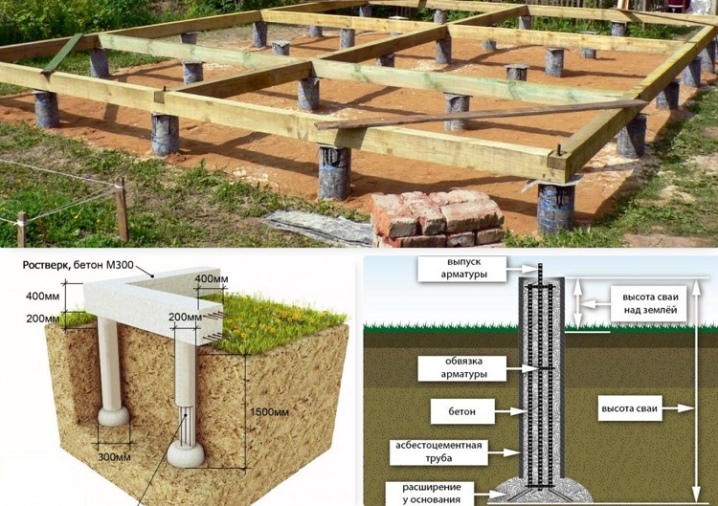

Increased grillages are used more often. In this case, the sole is exactly at the ground level. The tape is supported on a cushion of sand or gravel 10-15 cm thick. This part of the structure is equipped by removing a certain layer of earth, which will need to be replaced with the selected material. This approach allows guarantee protection against frost heaving, provides a free outflow of liquid (otherwise moisture would have accumulated indefinitely).

It is worth mentioning the features of recessed grillages. In this case, the tape is below the ground level. A shallow trench is being dug along the pile line. In its bottom, a layer of crushed stone is arranged - the same as in an increased grillage. Next comes the formwork chute; both reinforcement and concreting of the space created in this way are necessarily provided.

By type of construction

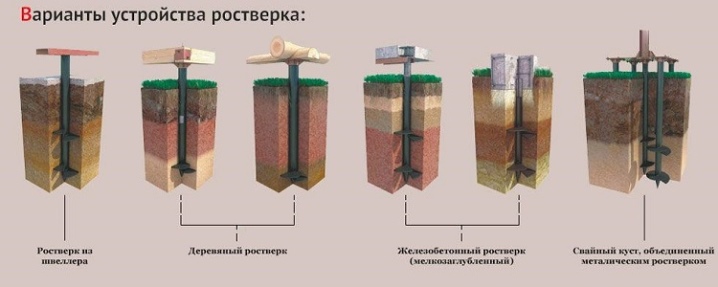

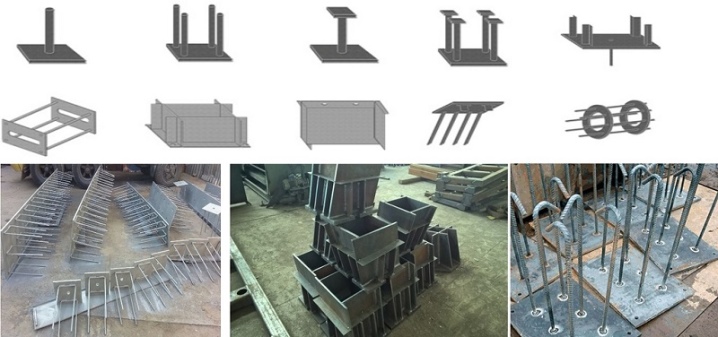

The main division here is between prefabricated and monolithic systems. The prefabricated version is often made of steel beams. Mostly they are welded together. This solution is very laborious and not very durable. In addition, the stiffness of the welded joints does not allow for a sufficiently good adaptation to the changing load. Prefabricated grillages are laid on pile heads. They are fixed, but monolithing is not required.

This approach is optimal for non-capital structures that will operate for 10 to 20 years. The monolithic version, which follows from the name itself, is a one-piece construction. Pouring takes place at the construction site itself. Monolithic grillages are additionally divided into slab and tape options. The construction of the support belt is most common.

However, in places with poor geological parameters, a slab may be the best choice.... Such a solution will require high costs, reinforcement with a thick layer of concrete and is very laborious. Only special technical requirements justify its use. One way or another, the grillage is used in columnar foundations. An intermediate type has also been developed, that is, a precast-monolithic grillage.

To create it, parts manufactured at the factory are used. They are grouped in the manner of a "constructor", using connecting locking and keyed elements. When the installation is finished, the entire assembly will have to be monolithic to obtain a continuous tape.

Such a solution is optimal for industrial and multi-storey construction, but in private practice it is rarely used due to its high cost.

Materials (edit)

Reinforced concrete grillages are classics of modern construction. They have excellent bearing capacity. Such products are stable and reliable in almost any environment. When using them, there is no doubt about the long service life of the foundation. In addition to concrete fillings, steel reinforcement plays an important role in the composition of such a grillage.

If the concrete perfectly accepts the compressive effect, then the steel increases the overall strength. The result is an optimal balance of flexible and rigid characteristics. Of course, all this is calculated very carefully. The structure can be reinforced with both isolated rods assembled into a flat frame, and with previously prepared volumetric frames. In any case, the reinforcement must have a large protective layer - only in this case the reinforced concrete structure works efficiently and for a long time.

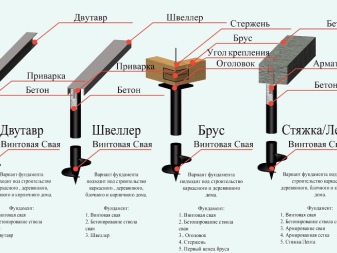

In some cases, it is applied metal grillage. For its manufacture, profile rolled products are released - a channel or an I-beam. This version of the foundations is distinguished by its decency and rigidity. Metal structures are equipped as part of a pile-screw base and in the construction of one-story houses. Channel bars are placed on the pile heads and fixed by welding; unfortunately, it will be impossible to count on high corrosion resistance.

In wooden houses, wooden grillages made of timber are often used. It is possible to lay the timber on piles only on top of a special gasket that prevents the spread of water. Roofing material or roofing material is usually used as it. The tree will have to be additionally treated with impregnations that reduce the risk of rotting.Brackets or bolts help to attach the timber to the pile; from a technical point of view, the design is the same as when using reinforced concrete, but without any reinforcement.

In the past, in the construction of wooden houses, flooring was prepared from logs in 1 or 2 layers. It was laid out on gravel. This approach allows you to build a small log or plank structure. Sometimes this method is still used today. However, another option appeared - joining logs to vertical piles.

It is not very reliable and tough. Therefore, there is no need to talk about the strength of the structure. As a result, such a grillage is not used in the construction of residential buildings, even one-story and with a low load. It is mainly used for gazebos and awnings.

Summer residents often use this solution, since wood is available and easily processed.

Dimensions (edit)

The usual section of the funnels will be 0.3 m. The typical length of the rods is 5 m. The number of columns must be calculated. It is determined taking into account the size of the houses and the fact that 1.5-2 m must be left between the posts. The depth is calculated individually.

In this case, the basic engineering recommendations must be taken into account. Normally, the piles go 20-30 cm above the ground level. The minimum width of the grillage is equal to the width of the base. If there is no plinth, then it is usually equal to the width of the outer wall. However, in any case, it is impossible to make a grillage already 0.4 m.

Manufacturers overview

Concrete and reinforced concrete grillages are ordered at enterprises for the production of building materials. Wooden products are often made by themselves or ordered from workshops. But the steel grillage can be purchased from many specialized firms.

For example, at the Cherepovets metallurgical plant, which is part of the Severstal conglomerate. Alternative proposals may come from:

- Ufa plant of metal structures;

- Kashirsky plant of metal structures and boiler building;

- plant "Remstroymash" (having solid experience in the production of a wide variety of equipment and structures);

- IPP "Ferrum" (supplying metal grillages even for areas with very cold climates).

Reinforcement methods

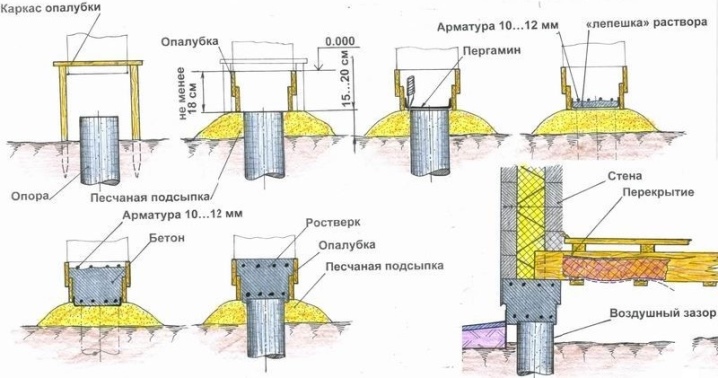

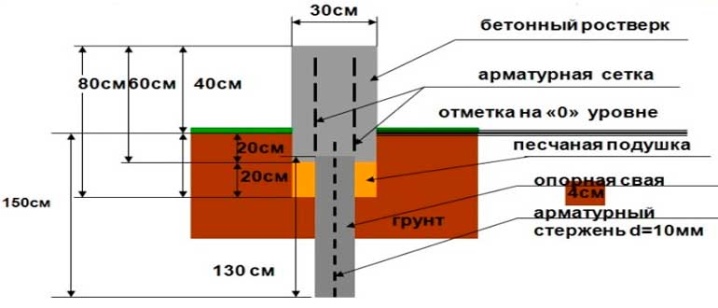

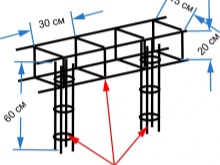

Modern pile-grillage foundations are distinguished by excellent characteristics largely due to the reinforcement. Their exact calculation is very difficult and requires the involvement of experienced specialists. Particular attention should be paid to strengthening the corners, because it is the joints that most often turn out to be the "weak points" of building structures. Reinforcement of monolithic grillages is carried out in 2 separate rows with a gap of 20-30 cm. These belts are connected longitudinally using wire or additional reinforcement held in place by bolt clamps.

It is not advisable to cook metal. The risk of steel deformation is unjustified here. The calculation and preparation of the scheme always imply taking into account the number of horizontal belts. It is also necessary to provide for connecting groups vertically, placed with a step of 20 cm. Deviations from this rule can only be justified by using a wire of higher power. Monolithic grillages are reinforced strictly using belts.

The frame must be made of a spatial type, using vertical beams of reinforcement. Their length should be such that nothing goes beyond the boundary of the structure.

The predominantly vertical rods are joined to the horizontally running belt using flexible wire. The work is completed when all the rods are laid and joined together. The lower tier must be protected especially effectively. Only then can the grillage be poured with concrete. Violation of the work sequence is unacceptable.

Working with tape structures is almost the same as reinforcing monoliths. The only difference is that the tape is located strictly along the perimeter of the bearing walls and it is there that it is strengthened. The obvious consequence is that you have to spend less rebar. Concrete consumption is also reduced.Another difference is the formwork installation method, or rather, the two-sided formation of the protective plane.

It will significantly reduce access to the fittings themselves. The connections are made only through the use of a knitting wire. Welding work is technologically unacceptable. When preparing a drawing of the reinforcement of the tape system, it is necessary to work out everything so that the rods and reinforcing beams do not sag anywhere. All elements must be located in strictly defined places and fixed there rigidly. In monoliths, it is customary to connect all the heads. Only adjacent structures are joined in the tapes. As a result, the calculation and the actual execution of the work will be cheaper. It is very important to carefully determine the cross-section of the grillage and take into account the presence of an air cushion under its plane.

Inexperienced designers often combine plate and tape details in diagrams. Then, during the winter heaving of the earth, they will undergo different stretching, the piles will quickly break, and the base will collapse. The cross-section and size of the piles are calculated after the design of the house has been developed, including the specifications of the floors and load-bearing walls. Then only the permissible loads can be calculated, the required types of elements can be determined and, accordingly, the thickness of the slabs can be selected.

With a strip format of the foundation, the grillage should be equal in thickness to the load-bearing walls or slightly thicker than them. It is important to understand that this thickness always takes into account insulation and decorative elements. In areas with slopes, it is necessary to initially select piles of different lengths. If the slope is too large, the foundation is built according to a stepped system. The reinforcement cage must not be placed on the ground.

In case of metal corrosion, a rupture of the soles of the pillars will be inevitable. When the skeleton is inserted into the well, it must be centered. The absence of such a procedure results in the emergence of the reinforcement outside the column or excessive thinning of the protective layer.

If, nevertheless, they resort to welding, the joints should not be in the corners and where the walls intersect. When bending the rods, the places of the folds are not heated in order to exclude the occurrence of microscopic cracks.

Features of creating a foundation

Before installing the grillage foundation, it is imperative to make a careful calculation and prepare drawings, which are always individual. The seductive simplicity of such a solution is only apparent; in fact, any mistake can be fatal. The pouring procedure is carried out in strict accordance with the flow chart, which necessarily stipulates, for example, safety requirements. When working on an industrial scale, the pile seats are equipped with powerful equipment.

In private households, construction drills are usually used. How deep to prepare the holes for installation depends on the strength of the soil and on the depth of their freezing. The formwork is formed from boards or plywood with a thickness of at least 2.5 cm. The formwork contours are set very carefully before concreting.

To make the grillage stronger, it is advisable to pour the solution in 2 rows, covering the reinforcement with a ball at least 3 cm thick.

The best choice would be to use a ready-made solution.... The brand of concrete is chosen as high as possible - you should not save on the foundation. The compaction of the mixture is carried out using a vibrating unit. Backfilling must comply with the profile SNiP. It is made only after the completion of all work on the arrangement of the foundation itself and after the concrete has been cured.

The voids are mainly filled with sand or sand and gravel mixture. It is easily accessible and wicks away moisture well. The work can be done even without the help of technology, in a manual way. But with a high level of groundwater, the sand will be washed out. Therefore, it is more correct in such cases to equip the drainage in advance and provide for an external barrier; on heaving soils, it is mainly advised to form hanging grillages.

Warming and waterproofing

Along with mineral wool, polystyrene foam can also be used. But it is better to use not its traditional look, but more modern penoplex. It perfectly resists compressive linear deformation and has a long service life. This material is also geometrically stable and does not change its properties upon contact with water. Biological stability is also a very convincing argument in favor of penoplex. Waterproofing is mainly needed for places with unprotected metal. But both concrete and wood must be insulated in the same way. Roll protection from moisture is divided into film and containing bitumen.

When laying roofing material or glassine, additional surface preparation will not be needed. Sometimes coating methods are also used. In this case, rubber mastics are used. Convenience of their use, however, also has a negative side - high cost.

In addition, the set mastic is poorly resistant to mechanical damage. Sprayed liquid rubber is praised for its durability, but it is also not cheap. It is necessary to protect from moisture not only the underground, but also the surface of the structures.

The comment was sent successfully.