USHP foundation (on the insulated Swedish plate)

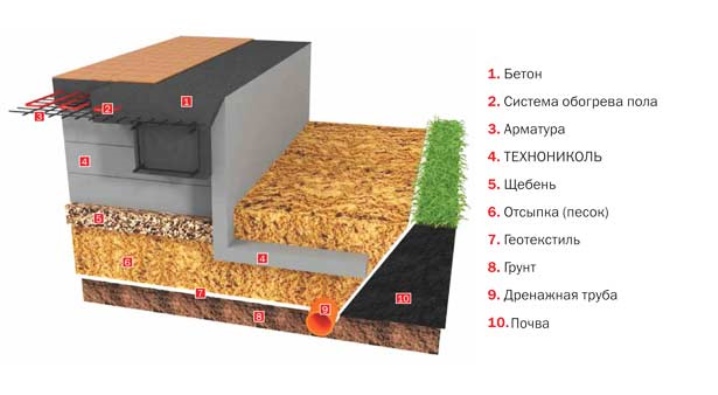

USHP foundation is a foundation built using an insulated Swedish plate (USHP). This type is a slab monolithic foundation, which has a floor heating system inside, and is insulated with a layer of foam plastic from below.

It can be used on soils with high (and low) moisture content and high groundwater levels. Suitable for the construction of lightweight structures from all basic types of materials.

Advantages

- floor heating system;

- the upper surface is smooth and even, which does not require additional costs for leveling the floor in the room;

- absence of any seams and joints on the surface;

- reduces the likelihood of freezing and, accordingly, heaving of the soil under the bottom of the building;

- during construction, the use of special (and expensive) equipment is not required;

- due to good thermal insulation, it will save money on heating inside the building in the future.

disadvantages

- not a very cheap kind of the base of the structure;

- cannot be used under structures with a large mass;

- not suitable for all types of soils;

- excludes the construction of a basement or cellar under the building.

Peculiarities

A distinctive feature of this base for a house is the location of a good thermal insulation material at the bottom and on its sides (perimeter). Also, additional stiffeners are installed at the base of the walls for greater strength and resistance to the force pressing from above. The small thickness of the entire structure makes it possible to reduce the time required for construction.

Construction stages

When creating a UWB foundation, there are the following stages of construction:

- creation of a pit by extracting the top layer of soil;

- compacting the bottom of the pit with sand and its ramming;

- installation of drainage pipes and other communications;

- filling crushed stone for and leveling it;

- installation of formwork around the perimeter of the pit;

- laying of lateral heat-insulating material from the inside along the perimeter of the formwork;

- laying of a double lower (main) layer of heat-insulating material - extruded polystyrene foam;

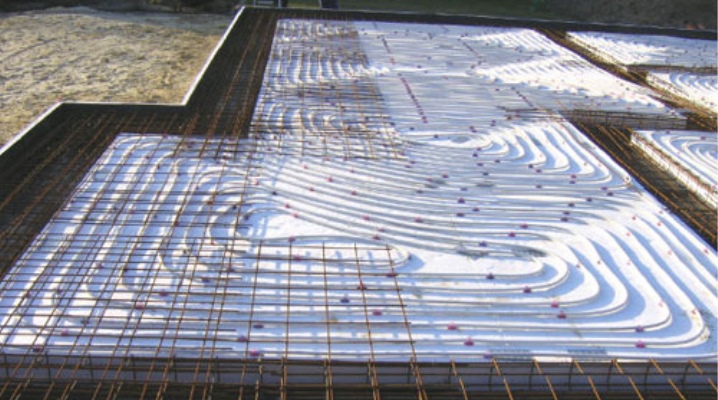

- strengthening the structure with reinforcement rods;

- installation and installation of floor heating systems;

- filling with concrete to a thickness of 100 mm;

- leveling the top layer after the concrete has set;

- surface grinding.

Separately, it is worth mentioning the cost of the USB foundation. Its cost is quite high, but it allows you to save money due to the absence of the need to use special equipment and in the future will save money on heating the premises. From all this it follows that this type is quite justified in some cases, but it cannot be universal for all cases of the need to construct the base of the building.

The comment was sent successfully.