Features of the ceiling duct units for the chimney

Cutting-through block (node) is a fire-prevention insert between the pipe and the wall. It protects walls from fire when they are made of combustible materials (wood, plastic), as well as non-heat-resistant blocks (like foam blocks or gas blocks).

What it is?

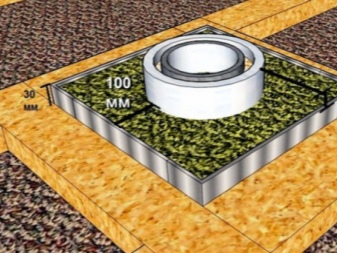

A PPU device for a chimney in a bath, in particular, for a sandwich chimney, which heats up during continuous operation of the stove for several hours or even the whole day (or night, depending on the schedule of the bathhouse), does not, in turn, overheat the wall through which the smoke channel passes. It is especially used in wooden buildings and buildings made of experimental materials. PPU is a square or round compartment, into which a seal is poured, which does not conduct heat well due to the presence of porous structures in it. A wall or ceiling, interfloor or attic-ceiling ceiling needs to be protected from high temperatures.

The module is purchased in a specialized building market - or assembled independently by a master who understands fire-fighting technologies. When choosing a product, take into account the diameter of the chimney and the location of the stove or heating boiler in relation to the ceiling, attic or interfloor floors.

Only by observing a number of safety rules for installation and operation, it is possible to install it correctly.

What are they?

A passage through a wooden floor is used in a bath or sauna, all kinds of steam rooms, heating rooms or compartments of country and private houses.

The brick structure is part of the wall or ceiling, as it can be additionally fastened with a cement-sand mortar. From the outside it will seem that the brick chimney is a single whole. The chimney is cut by means of a thickening at the passage. The bricks are stacked in three rows along the height of this transition. Violating this technology, you will not achieve the best traction, which is why the room can become smoke-filled, up to a fire.

The transition box is also realized from high-temperature drywall. Mineral wool or asbestos is prepared for it in advance. Plasterboard partitions are installed, and the free space between them and the pipe is filled with highly porous and non-combustible insulation. From above, after the basalt mineral wool, expanded clay is poured, penetrating into all the residual free spaces, while the insulation will not suffer, since the cotton wool will not crumple and the heat retention will not deteriorate.

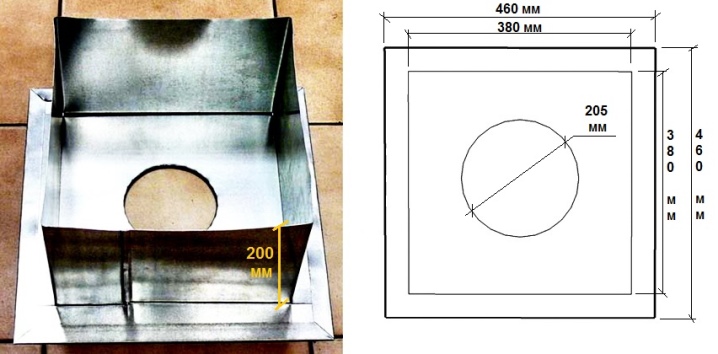

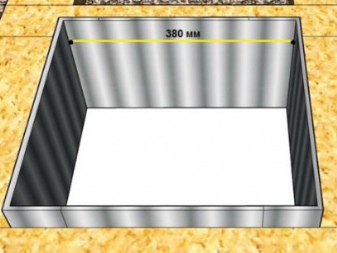

The steel box is made of stainless steel. At the same time, a hole is cut in one of its walls - along the diameter of the outer wall of the sandwich pipe. The void is filled with expanded clay, basalt mineral wool or other non-combustible materials.

Building regulations

According to GOST, a square opening of 1 m2 is cut out in the ceiling or in the wall, a passage block is inserted into it. The distance in the bath between the beams will be required equal to 1 m, which is not always the case. Simple polyurethane foam is made four times smaller - a square with a side of half a meter. But the rule of installing a simple PPU does not allow the use of a pipe diameter greater than 20 cm. At the points of contact along the perimeter of the PPU, foil is glued on the heat insulator from all four sides. Foil insulation prevents the wood from heating up - the foil layer reflects the heat back.

The main requirement is that a metal or brick chimney must not heat walls and ceilings above 50 ° C. An extract from SNiP 41-01 as amended in 2003 is responsible for this requirement. Without a ceiling transition, it will not be possible to comply with this (immutable) rule. In the absence of direct contact with a pipe that has heated up, it is enough for the furnace to warm up to significant temperatures, for example, up to 500 degrees, so that the wooden structure surrounding the pipe begins to burn. This entails a loss of strength of the beams with their subsequent collapse. To prevent this, a layer of thermal insulation is needed, which will not burn out when the chimney is practically in a red-hot state for a long time.

For this, a chopping block is needed, which creates a barrier around the chimney.

What can be filled?

Expanded clay and mineral wool come to the fore among the fillers. However, they are not limited to filling the empty space. Some heaters, for example, expanded clay and mineral wool, can be combined without losing the heat-retaining properties of the passage block.

Basalt and mineral wool

Simply put, mineral wool is almost the same fiberglass used in Soviet-made refrigerators. Working with it is unsafe, as it requires the use of a respirator that protects the lungs of the worker when working with fiber, glass dust from which can cause silicosis. But mineral wool, like pure basalt fiber, is able to withstand heating up to several hundred degrees without losing the "whipped" state. But it is capable of caking, exudes formaldehyde when heated, which, in turn, belong to substances that cause cancer. Cotton wool does not tolerate getting wet - its heat-insulating properties are lost at the same time.

Expanded clay

Expanded clay insulation is much superior to cotton wool - after drying, it easily restores its heat-insulating properties. The disadvantage is the use of special containers, with poor-quality insulation, it can spill out. It is harmless, as it is made of sintered clay.

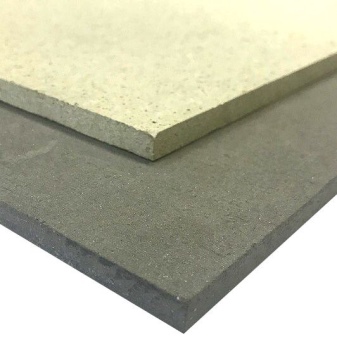

Minerite

Mineral insulation includes cement and sawdust, "flavored" with mineral additives. High temperature - withstands heating up to 600 degrees. Does not release carcinogens.

Asbestos

Although asbestos is produced mainly from natural minerals, it can cause, again, cancer in people in the room where the stove is operating, the chimney of which is closed from the wall or ceiling by asbestos filler. Its dangerous effect on human health is achieved mainly by poisons, the vapors of which are released when heated. Excluded from the list of materials used in residential buildings, limited for use in metallurgical production in workshops where a blast furnace is used. It is relatively safe when cold.

Clay and sand

Clay-sand fillers, yielding in terms of heat retention to more modern composite and synthetic materials, occupy an intermediate position between them and solid materials, which, in turn, have good thermal conductivity.

Clay and sand are natural and harmless, which has been proven by thousands of years of their use as all kinds of fillers.

Installation steps

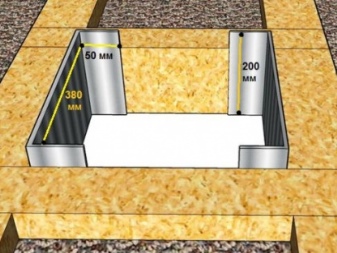

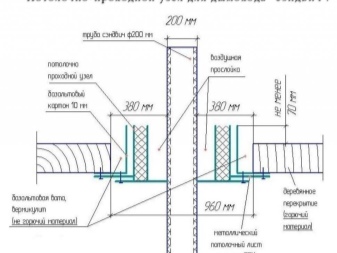

If there is more than a two-centimeter layer of non-combustible and heat-resistant plaster between the chimney and the main wall materials, according to TU, it is possible to reduce the gap between the pipe and the wall so that the total PPU gap does not exceed 35 cm.But this value is a necessary minimum, which is impossible to do without. The height of the plaster should be at least 7 cm higher than the thermal insulation layer. The size of the indent from the pipe to the wall on all sides can vary between 20-50 cm. The thickened walls of the cutting box make it possible to reduce the distance (but not below the minimum) due to additional protection from the heat of the heated pipe.

The most reliable materials for the box are considered to be brick (you can take refractory, for example, fireclay), stainless steel sheet, flame plates or minerite filler. The distance between the wall and the casing should be at least 1 cm, that is, fastening the box close to it is prohibited.

Preparation

At the initial stage of installation, a square of 1 or 0.25 m2 is cut into the wall or ceiling (or, if the construction is going on in a new project, they are preparing). With closely spaced beams and rafters, an additional wooden box is lined with minerite from the inside. The box is fixed on the beams, then a pass-through block is installed in it. The roof should ideally be made entirely of non-combustible materials. Coating wooden structures with non-combustible impregnations will not protect them from charring when the fire intervals are still violated.

Installation

A step-by-step guide to installing a chimney with a bushing is as follows.

- The sandwich pipe allows you to lower the temperature of the inner pipe - relative to the outer - by 250 °. The sandwich chimney prevents condensation from forming inside the pipe structure.

- A single-walled pipe is first placed on the sauna stove, then, upon reaching one meter, a transition to a double-walled pipe is installed. From a double-walled chimney, you can switch to a sandwich chimney using the appropriate adapter.

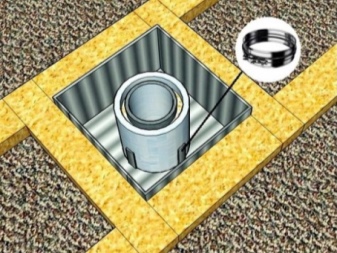

- The "sandwich" itself is "sewn up" into a wall or ceiling box. The use of such a complicated scheme allows you to finally exclude overheating of the pipe going from the furnace to the outer (above the roof) section, allowing it to last longer. The use of joints in the attic or at the level of the wall / floor / roof is excluded.

- Strictly horizontal pipe sections should not be abused. To prevent the thrust from going backwards, it is recommended to use upward inclined, diagonal, not 100% horizontal sections. The length of a strictly horizontal section should not exceed 1 m. The use of more than three turns in the chimney is unacceptable.

- At the exit, rigid fixation of the pipe is unacceptable - the steel expands when heated.

- Too closely spaced beams, especially wooden ones, need additional protection with a minerite heat insulator.

- Fastening the chimney transition box is allowed by means of self-tapping screws - while their heads must be reliably isolated from the heat source so as not to cause the wood floor to be scorched with their help.

- The opening of the adapter block must strictly coincide with the location of the outlet pipe, since it is forbidden to deflect the chimney by more than 1 mm to either side: the joints do not fit tightly, the exhaust gases may exit directly into the room where the furnace is operating.

- If the chimney is installed in a two-story building, it is recommended that one meter after leaving the floor on the second floor switch again from the sandwich section to a single-walled pipe, which will allow high-quality heating of the room located above.

- Before entering the attic space, where the second same box is located, the transition to a double-walled pipe is used again, and then to a sandwich structure, which extends to a level above the roofing "pie".

The installation of a transition box between floors, in the walls, is no different from its installation in the attic-ceiling ceiling. A roof made of metal or corrugated board is equally well suited for the output of a sandwich chimney: both are profiled steel.

The comment was sent successfully.