Chimneys made of stainless steel

Stainless chimneys, unlike their cast-iron counterparts, although not so durable, can still partially solve the problem of trouble-free smoke removal far beyond the heated room and the structure as a whole.

Advantages and disadvantages

Chimneys built of stainless steel have some positive qualities compared to their brick counterparts.

-

Such products easily adapt to any heating system scheme - gas or wood-burning. They are not required only when heating the air inside the building by means of electric heating elements.

-

Relatively high indicator of wall strength. The thickness of the sheet steel is such that it is not always possible to crush the chimney or damage it with bare hands.

-

Light weight: the chimney walls reach a maximum of 2 mm. This is dictated by the conditions that stainless steel can provide for uninterrupted smoke removal.

-

Metal chimney, if it is not a thick-walled capital pipe, does not require a reinforced foundation and heavy-duty supports.

-

Service life of stainless steel - up to 30 years old subject to the rules of operation.

-

High temperature indicators: stainless steel does not lose its properties when heated to 600 degrees. For the purposes of the experiment, the pipe was heated up to 900 Celsius. At this temperature, it glows with a bright red color, while it does not perforate and retains its shape and location.

-

Stainless steel, like any high-strength steel alloys, not prone to damage from vibration and shock to a certain extent.

-

Stainless steel pipe does not suffer from sudden heating and cooling.

-

No susceptibility to oxidation from condensate water: when carbon dioxide and water combine, a weak solution of carbonic acid is formed, which does not affect the state of the stainless steel.

-

Stainless steel is safe: it does not emit harmful substances.

-

Stainless steel pipe, like galvanized steel sections, to a great extent easily assembled.

-

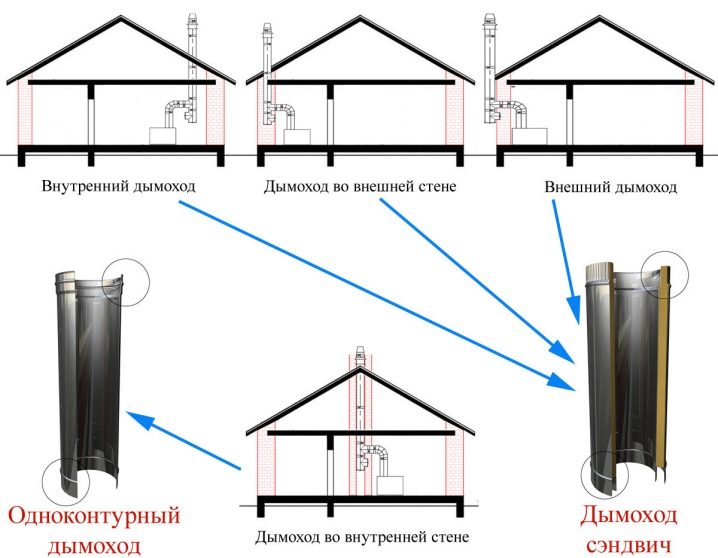

The chimney can be installed as a through pipelinepassing through the attic-ceiling slab, the attic space and the roof (roof), and go out through the wall, rising up to the side of the attic and the roof.

-

Steel chimney easy to replace leaky sections and cleaned from soot.

There are also flaws in the stainless chimney.

-

High cost - stainless steel is several times more expensive than usual.

-

Thermal insulation of a single-walled chimney outdoors and in unheated rooms: the absence of an insulator can cause the accumulation of condensate with its subsequent evaporation, and part of it can drain directly into the boiler.

-

Not quite attractive appearance of the chimney - it is on display.

The number of pluses, as you can see, easily outweighs the possible flaws of such a solution.

Views

The stainless steel chimney differs in design and shape, diameter and specific contour. Before calculating the scheme and laying the pipeline, craftsmen choose a suitable product based on a certain classification.

By type of execution

Flexible chimney is a corrugated pipeline, carefully bent so that the shear waves that make up a single whole do not deform. Otherwise, the section of the pipeline would be partially blocked, which would cause difficulties with the removal of smoke and exhaust gases. Hard chimney - smooth-walled pipeline. Unlike flexible pipelines, rigid ones are supplemented with branching pieces (tees) or elbows.

By form

The oval shape of the chimney is rarely used.... It is used only in the main (collective) exhaust shafts, whose brick pipe on the roof of the building is covered with a long head that protects the inner space of the pipeline from atmospheric and condensate moisture. Basically, they use round chimneys with a cross-sectional area of sufficient power for a boiler or furnace. This value is indicated in the pipeline design, whose task is to effectively remove exhaust gases and smoke from the boiler or furnace, not allowing them to penetrate into the structure.

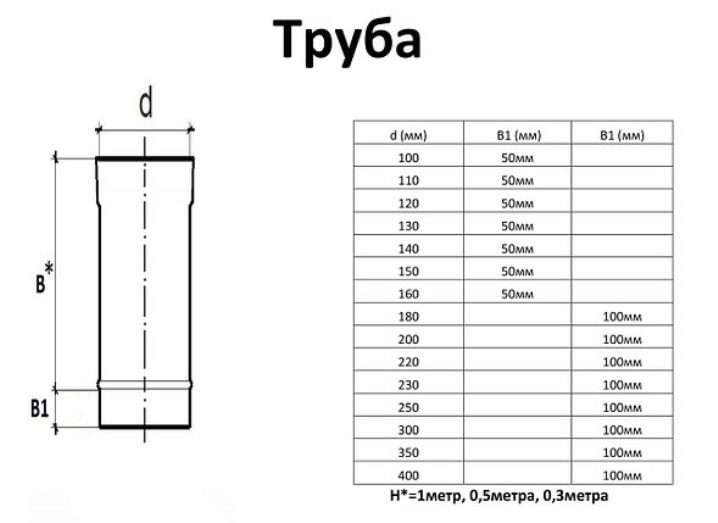

By diameter

In the market for gas and stove equipment, chimneys with a diameter of 100, 110, 115, 120, 130, 140, 150 and 200 mm are in demand. For most heating gas and solid fuel boilers, wood stoves and fireplaces, whose thermal power ranges from 10-20 kilowatts, this range of pipe diameters is sufficient. Industrial furnaces, for example, at steel mills, have a significantly larger pipe diameter: most often in production, a pipe shaft made of refractory bricks is used, rather than stainless chimneys.

By the number of contours

A single-circuit chimney is used in steam rooms and showers, where the air in the room is heated to very high values. But when the pipe leaves the room through the wall or overlap to the street, a so-called transition to a sandwich is installed - a double-walled pipe, in which a heat insulator is placed between the outer and inner walls. Expanded clay, basalt mineral wool or vermiculite is mainly used as a heat-insulating material: all three materials do not ignite and do not support independent combustion.

Another type of double-circuit chimney is coaxial - the outer and inner pipes are not fenced off from each other by anything other than an air gap. This means that air from the street is pumped through the external circuit - the space between the external and internal pipes - by the gas boiler. Exhaust gases are discharged through the space limited only by the inner tube.

Double-circuit pipes are fireproof - their outer wall hardly heats up. The task of the sandwich is to exclude moisture effusion on the inner surface of the second (central) pipe. Moisture flowing into the boiler can extinguish the fire, and the heating will often turn off spontaneously.

Chimney steel grade

The best stainless steel is the American 310-S grade. This alloy can withstand heating up to 1000 degrees without changing its properties. Other stainless steel is designed for only 600-700 degrees of heat (incandescence). The domestic substitute is stainless steel with a mass percentage of chromium of the order of 14-20% (X14 ... X20).

Manufacturers

Russian manufacturers are represented by the following enterprises: Leningrad companies "PromDym", "PILK", "Vulkan", the Armavir brand "Prok", the Sverdlovsk firm "Ventrauf" and a dozen of similar names. Chinese analogs of stainless steel are also made from Russian metals and coal - there are very few metal ore deposits in China. Chimneys of American manufacturers are several times more expensive than similar Russian products.

Choice

The chimney for a solid fuel boiler in a bath must necessarily have a diameter that coincides with the calculated... For chimney ducts that have access to the street directly through the wall, and not through the roof and the overlap between the ceiling and the floor of the attic, additional fasteners are used to fix the smoke duct on the wall from the outside.

As knees, it is preferable to choose not those that are designed for an angle of 90 degrees, but to give preference to an angle of 135 degrees.This will help to replace the horizontal section with a diagonal one, which does not allow smoke to stagnate and create a reverse draft, fraught with the ingress of carbon monoxide and a smoke screen into the structure.

If possible, look for the hottest grade of steel. They will last a long time - up to 30 years: such a chimney can be heated almost to a bright orange color, while it will not lose its shape. Other grades of stainless steel at a thousand Celsius would have begun to sag a little.

Do not choose pipe and elbow sections, as well as a head with a smaller diameter than intended by your heating system design.

For outdoor areas, choose a sandwich chimney, for a gas boiler - a coaxial one, while in the second case, you cannot make the transition to a single-wall one in any of its sections.

DIY step-by-step assembly instructions

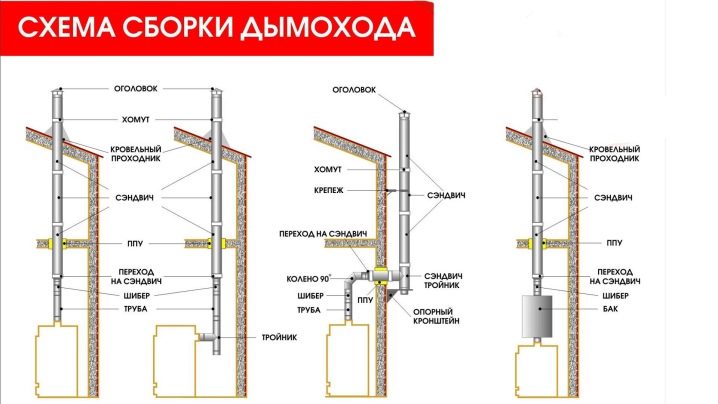

To install a chimney outside the building, do the following.

-

Install a boiler or stove, or build a space for a wood-burning fireplace in a niche... Equip the mouth of the flue and flue gas outlet (connection for the flue gas pipe).

-

Drill one above the other - vertically - several through holes for clamp fastenings of the chimney sections.

-

Push the hairpin pieces into these holes. - and fasten them on both sides (inside and outside) using nuts with press and lock washers. Screw locknuts with lock washers onto the free ends of the studs outside the building, and screw on the clamps that will hold the chimney in place. Use the locknuts to secure the clamps completely so that they do not unscrew spontaneously.

-

Thread the sections into the clamps, dock, tighten them. On the top of the outer part of the chimney, put the head of the pipe.

-

Attach the swivel elbow to the bottom of the chimney... Bring the next section into the room.

Check all joints. The chimney should not have through gaps between sections.

Pipe installation

Having assembled the main part of the chimney, install and connect the boiler to the chimney pipe, installing another elbow and an additional section, into which the pipe-neck of the boiler installation enters, which removes exhaust gases from the boiler. For furnaces with a round or oval exhaust of fuel combustion products, the sections, elbows and head must completely coincide in the shape of the cross-section of the pipeline.

Chimney sections must be joined tightly - gaps and any gaps visible to the eye must be excluded. For a chimney in which the formation of moisture is excluded (appropriate thermal insulation is installed), the sections are docked with an overlap directed downward: this approach will exclude the passage of smoke and exhaust gases directly into the room where the furnace is organized.

The horizontal section of the pipe should not be longer than 1 m.

This restriction does not apply to the diagonal transition - in this case, the smoke does not move horizontally, but always rises to the top.

The number of rotary sections in the chimney should not be more than three. If this rule is violated, then a fan exhaust will be required to draw out smoke on a chimney that is too long and winding. For a stove, which almost always smokes, a fan cannot be installed: the accumulation of soot when the motor overheats or accidentally overshoots of sparks can ignite these layers, and the motor will simply burn out along with the propeller. A similar solution is used mainly in boiler rooms, stove and fireplace systems operating either on environmentally friendly fuel, or in the mode of pyrolysis afterburning of solid and liquid fuels.

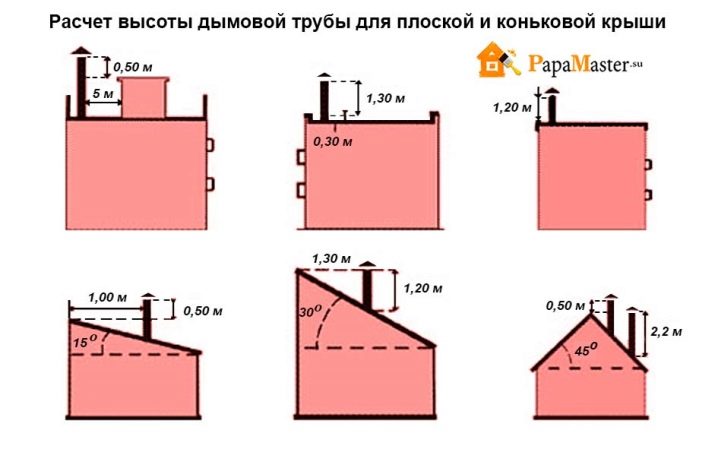

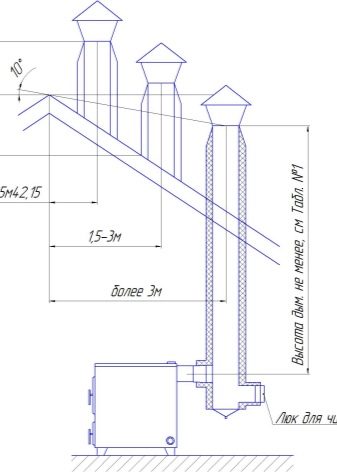

The chimney height above a flat roof is up to half a meter. At a distance of 1.5 to 3 m, so that no back draft is created, the chimney head is installed vertically with the ridge of the roof. The distance from the ridge of the roof less than 1.5 m also obliges to raise the head above the level of the ridge of the roof by 50 cm.If this distance is more than 3 m, then the head falls 10 degrees below the horizon line - relative to the ridge.

Low-melting aluminum pipes must not be used - at the first serious incandescence, the aluminum falls apart. It only needs 660 Celsius to turn into liquid drops.

The horizontal section of the pipe must not be underestimated either indoors or outdoors, below the horizon by at least one degree. This will lead to the fact that the smoke gets stuck in the chimney in this place and very quickly begins to penetrate into the room. To counteract back draft, the chimney height (total) must not be less than 5 m.

It is allowed to "sew up" the pipeline for the exit of smoke and exhaust gases into the wall or overlap with metal sheets. However, the area covered by these sheets, external and internal, must be, according to fire regulations, at least 1 m2 per one such sheet. This will help to avoid the ignition of combustible structures (for example, attic-ceiling logs), fiberboard sheathing and others: all these materials are moved away from the hot pipe at a safe distance, while their sudden ignition is excluded. Insulation of brick, masonry and gas silicate masonry, in order to avoid overheating, is performed in the same way. Instead of sheet steel, you can use fireclay (refractory) bricks, from which traditional stoves and fireplaces are built, burning wood and organic waste.

For coaxial chimney it is forbidden to install the transition to a single-wall: you can lose traction from the street, because of which you have to keep any retraction open (for example, a slightly open window) even in severe frost. However, the transition to a sandwich and vice versa, to a single-walled pipe, is used successfully, for example, when the secondary heat from the furnace, released locally in this section of the pipe, is used to heat the water for a bath. An alternative solution for a single-wall pipe inside, in the firebox, is a heat exchanger, from which, for example, heat with a coolant goes to a radiator battery in one or several rooms of the building. By this principle, by the way, wood-fired stove heating is built: the length of the chimney allows you to fully use the rest of the heat obtained during the combustion of wood and / or garbage.

The comment was sent successfully.