Types of master flush for the chimney and their installation

One of the most difficult units is the passage of the chimney through the roof structure. The main task is to ensure tightness and prevent fire. To obtain this result, it is necessary to use a roofing seal such as a master flush. This product is offered on the market in different versions.

We would like to bring to your attention more detailed information about the gasket, its advantages, selection criteria and recommendations for self-installation in different ways, depending on the material from which the roof is made.

What it is?

The chimney master flush is a flexible sealing system with high elasticity. Its main purpose is sealing. The product is installed at the intersection of pipes in the roof. These products are used for the installation of chimneys and other communications in various premises. The main characteristics include practicality, safety and durability.

Manufacturers produce master flush for pitched and flat roofs. On the market, you can find several types of products from certain materials, each of which has its own characteristics and advantages. The security element has been in great demand in the construction industry for a long time. Everyone can handle the installation; this does not require special skills or various tools.

The main advantages include elasticity. The bushings are made of rubber, therefore they are flexible and at the same time perfectly adhere to the pipe, which provides reliable protection against any leaks.

The versatility of the master flush lies in the fact that it is suitable for metal roofing, slate, corrugated board and so on.

The strength index is quite high, the material is dense and porous, therefore it easily copes with mechanical stress and is not afraid of damage. As for the service life, rubber penetrations serve for many years without losing their original characteristics. The material is resistant to temperature extremes and even to a chemical environment, so the product will not require replacement for a long time.

It should be noted that the master flush can be installed during the arrangement of the heating system, since it can withstand high temperature indicators. The product is designed to form roof transitions. On the market, you can find aisles in several formats and configurations, it is also possible to choose the appropriate shape and size.

Experts note that the product has long become an excellent alternative to traditional aprons. The cuff is tightly adjacent to the pipe, so not only moisture, but even dust does not get inside, and this is important.

What are they?

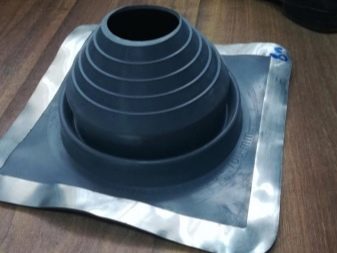

In shape, the penetration is a stepped pyramid with a rectangular base, which can be made of either rubber or silicone. Each step has its own diameter so that it can be matched to the corresponding pipe size. The passage is put on through the head and moves to the base of the site, where the chimney is brought out to the roof.

Models on the market can be made of rubber, which belongs to synthetic materials. Such products have a high rate of elasticity and flexibility, in addition, the penetration perfectly protects against moisture.This option is best suited for places where the temperature does not exceed 120 degrees. This rubber has a porous structure, it is important to take into account that the material has a low resistance to chemicals that are contained in oil.

Silicone master flush is used for chimneys where the temperature reaches 130 degrees. It should be noted that this option is great for conditions above 200 degrees. If solid fuel is used for heating, it is better to install a silicone penetration, as it is not subject to fire.

It is important to remember that such material is not resistant to sunlight, so it serves a little less.

As for the configuration of the master flush, it can be different. The model may have a reinforced metal flange, which will prolong the life, but the fit will not be as tight. Corner cuffs are available for shallow roofs. A conical product with corrugations can change the angle, you just have to tilt it in the desired direction. If we are talking about a flat roof, it is enough to place the penetration perpendicularly.

The element can be square or rectangular, but it must be equipped with rings in the center, which can protrude both down and up. Additionally, the master flush is equipped with an aluminum insert that reinforces the base. In the description of products, the permissible diameter is always indicated, so you can find a penetration from 100 mm to 400 mm, and even more, depending on the place of use.

Nuances of choice

To choose the right quality penetration, you need to know the characteristics of the roof and the parameters that you need to pay attention to. You can do this yourself, the main thing is to take into account several nuances. It should be noted that it is not enough to know one chimney size.

The first step is to find out what material the roof is made of and whether it is flat. For a sloped roof made of polyprofile without relief with an angle of up to 45 degrees, a product with a reinforced flange is required. If the slope is slightly greater, it is recommended to take a different seal. For a flat roof, equipment is required that has perpendicular collars. If the covering is slate or tiled, the penetration should have enlarged flanges.

For some types of chimney, the standard master flush is not suitable, especially if the pipe has a square cross-section, so you will need to take a rat with a fastener. When choosing a penetration material, it is necessary to build on climatic conditions and temperature differences.

If we are talking about a gas hood, then a rubber element is suitable, but for a stove chimney it is better to take a silicone seal.

The type of house does not in any way affect the search for a suitable master flush, it can be brick or wood, the main thing is to take into account the peculiarities of the roofing material.

How do I install the system?

Correct installation of penetrations plays an important role, so first you need to study the instructions and follow the recommendations of specialists, despite the fact that the task is simple. The first step is to take into account the material from which the seal is made, as well as the conditions in which it will be mounted.

On a flexible basis

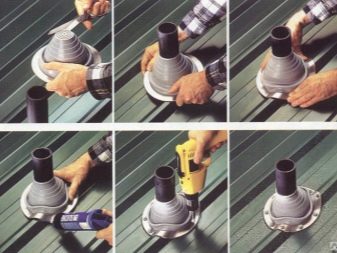

This option is intended for metal roofs. First, you need to decide on the place of the cut, while you must not forget that the diameter should be 20% less than the chimney opening. In the work, roofing scissors are used, then the cut will be even.

The pipe must be soaped or wet to make it easier to put on the cuff. Then you should make marks around the edges, raise the penetration in order to apply the adhesive, and then press firmly. At the final stage, a sealant is used.

With rigid rigging

If there are metal strips along the edges of the master flush, the installation of such a remnant is no different from the one described above. In this case, the coating must be profiled to ensure a snug fit. Before work, you should stock up on hexagon self-tapping screws. At the end, fasteners are used that are screwed into the bottom of the profile.

When repairing

If it is not possible to fit the collar on the chimney, there is a special design for roofs with a gap. If you need to repair the roof, you will need to get scissors to cut off the upper cone of the seal, then unscrew the valve and wrap the pipe. At the end, it is required to close the locking system, raise the edges to apply the adhesive solution and press until completely secured.

For roof tiles and slate

Installation of the penetration on the metal tile is easy to do, the cone system in the seal is also cut off - this is required for a better fit to the chimney. The top of the base is tucked under the roof, and the bottom with the sides goes under it. To prevent precipitation from entering under the coating, it is necessary to bend the top strip.

All problem areas and cheeks are covered with silicone.

For corrugated board

If you have corrugated board, you can mount a master flash in exactly the same way as on a tile, following some recommendations. Sometimes the seal is tight, so for improvement, the pipe is covered with a soapy solution that will provide sliding. Beginners sometimes make mistakes with cutting, but you should not rush to throw away the element.

You can take a waterproof sealant, screw the screws on top and after a while they will start working perfectly. You do not need to make many holes through which moisture will enter. Kriza is placed on a skate, the top is placed under the ridge strip.

If the roof covering is not uniform, but with overlaps, the top of the penetration must be moved under the adjacent part so that the water flow is continuous. If you follow these steps in order, the operation of the seals will be long and reliable, and this is the most important thing. Such work can be carried out with the roof of a residential or commercial space, as well as in a bathhouse, in factories and other places where a chimney is required.

As you can see, the operation of the master flush plays an important role in ensuring the tightness of the chimney. Thanks to different types of gaskets, you can choose the material that will serve for a long time and faithfully. The main thing is to carry out the installation according to the type of roofing material, following the recommendations described above, and you will not need to worry about repairs for many more years.

For information on what errors occur when installing a master flush for a chimney, see the next video.

The comment was sent successfully.