Everything you need to know about chimneys

Only after finding out everything about chimneys, it will be possible to clearly equip the heating in the house. The installation of chimneys for stoves when using ceramic communications and variations from bricks has its own characteristics. Additionally, it is worth dealing with heat exchangers for the chimney system, installation and arrangement of channels in general.

Peculiarities

It is theoretically possible to burn fuel in furnaces and boilers without a chimney. But the effectiveness of such a solution will be very low. You will have to spend an exorbitant amount of fuel and, in addition, put up with the fact that it will burn normally only under very favorable conditions. The device of chimney systems - in spite of the seeming external simplicity - is not limited to "sticking a pipe on the roof". This is a really complex complex, which ultimately provides:

-

excellent fuel combustion;

-

increasing the level of traction;

-

accelerated heating of the case;

-

fast passage of the dew point during warming up;

-

long service.

Views

The chimney for long burning stoves is quite simple to arrange. It should be oriented strictly vertically. A device that protects against atmospheric influences is placed on top. The design contains a collection tray. Peculiarities:

-

pipe height - at least 5 m from the boiler or furnace;

-

raising above a flat roof by at least 1 m;

-

Efficiency at the level of 90%.

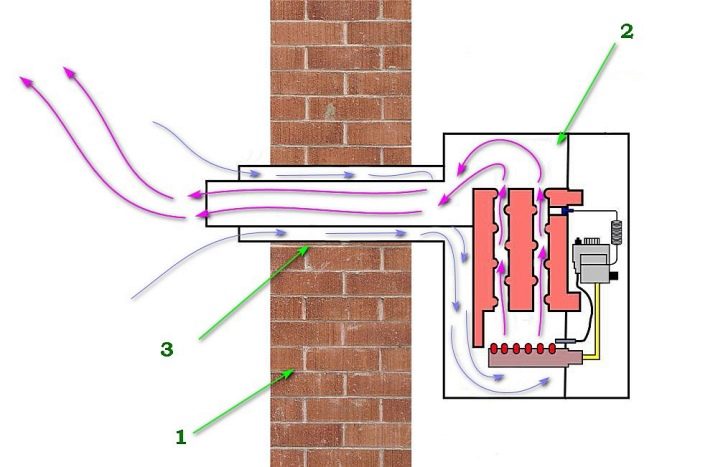

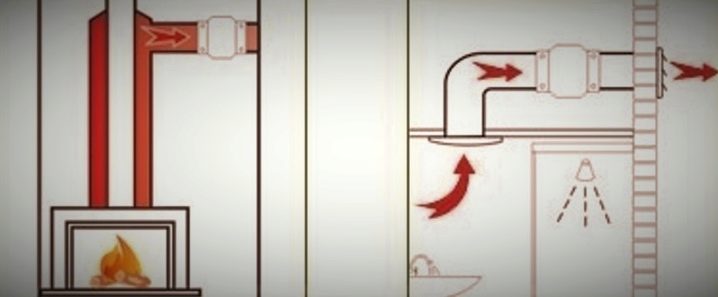

A completely modern and even fashionable chimney is a convector. It is appreciated for the accelerated heating of adjacent rooms. The bottom line is simple: heat is taken away from the flue gas ejected outside. With strong heating, the pipe begins to emit infrared rays. However, the use of a convector protects against this problem.

Convector flue ducts are considered completely safe, even when installed in wooden houses. Relatively cold air enters from the outside through the outer pipe. Hot gases are removed through an internal channel.

This solution works well even on the coldest days. The size of the lumen does not play a special role.

Chimneys are made of non-combustible materials. However, along with traditional solutions, ceramic products are now used. They can also be provided with sandwich kits. True, the cost of such solutions is very high. Ceramic structures are used in conjunction with:

-

ovens;

-

fireplaces;

-

boilers in baths, private homes and country cottages.

Ceramic can be used to make round and square pipes. They have special thermal insulation. A relatively cheap option is a mat made of mineral wool mixture, a more expensive version - with a "shell" - is more convenient. Concrete chimneys in the shape of a square or rectangle can also be used. The frame is combined with the support and the internal protection system.

Returning to ceramics, it is worth emphasizing that it:

-

survives temperature fluctuations;

-

due to the smoothness of the walls, it grows overgrown with soot relatively slowly;

-

easy to assemble;

-

may also include ventilation channels;

-

does not corrode;

-

serves 20-30 years.

However, ceramic structures weigh very impressive: 1 running meter is equal to 140-160 kg. With an identical cross-section, stainless assemblies can be about 10 times smaller. A significant mass of ceramic products does not allow you to do without a foundation support.

The cost of such products is also very high, and it is not easy to assemble it.

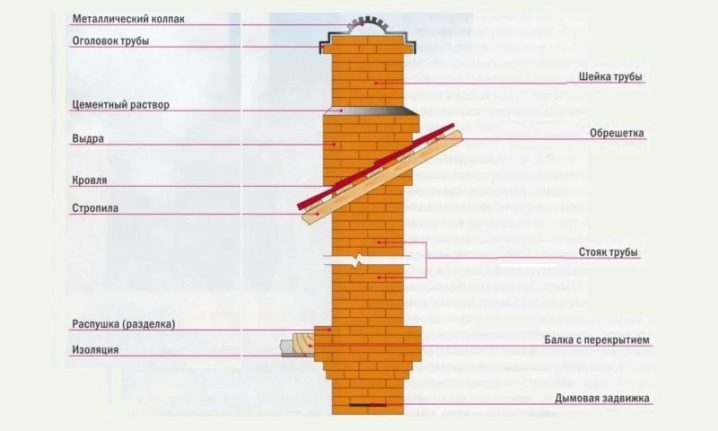

A brick chimney is also in demand. It is often used for solid fuel boilers. These complex models have, first of all, a head, that is, a "peak" hanging over the lower parts of the pipe. Also details of brick chimneys are:

-

neck;

-

otters;

-

aprons;

-

fluff;

-

risers.

Heads can be covered with tin umbrellas, excluding the penetration of debris and water. With proper laying, decent traction is guaranteed. But excessively wide chimneys lead to waste heat. Brick structures are quite reliable and can withstand heating up to 660 degrees. These properties guarantee efficiency even when adjusted for the increased cost of brick and masonry work.

Chimneys are often made of stainless steel. It is capable of transferring up to 900 degrees. This solution is versatile and practical, it allows you to get excellent results. The fees for steel structures are low.

However, regardless of the material, you will have to equip the chimney with the help of auxiliary equipment.

Optional accessories

The use of heat exchangers is recommended because they provide increased efficiency. Technically, it is a hollow body with inlet and outlet connections. A special block is provided to inhibit exhaust gases. Basically, this problem is solved with the help of valves with cutouts, placed on the axis. Models are simpler without these components.

Most often, heat exchangers are made of food grade stainless alloy. Its characteristics are maintained even at elevated temperatures. During the welding process, the seams are relatively strong. Galvanized steel can only be used where the temperature does not exceed 200 degrees. The heat exchanger can be mounted relatively easily; he himself is also divided into air (classical) and liquid types.

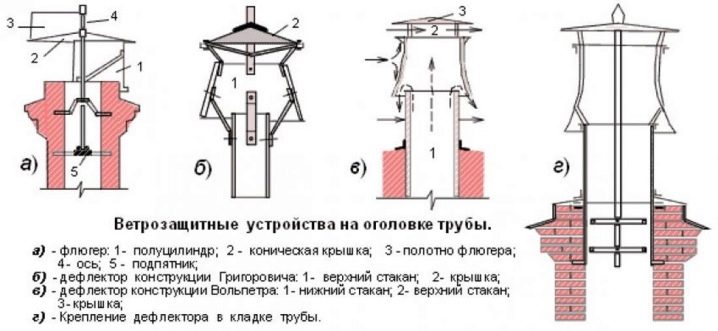

Economizer is a subtype of heat exchanger. It is often also considered that this is the convector already mentioned above. The deflector to increase traction also deserves attention. In addition to its main function, it also excludes the ingress of snow and raindrops, and various litter inside the chimney.

The advanced deflectors are also distinguished by their expressive design.

Even the simplest deflector structures, however, can increase traction by 20%. Thanks to this property, they help to improve the combustion of fuel and the efficiency of its use. The constituent parts are:

-

upper and lower cylinders;

-

branch pipes;

-

caps;

-

fixing brackets.

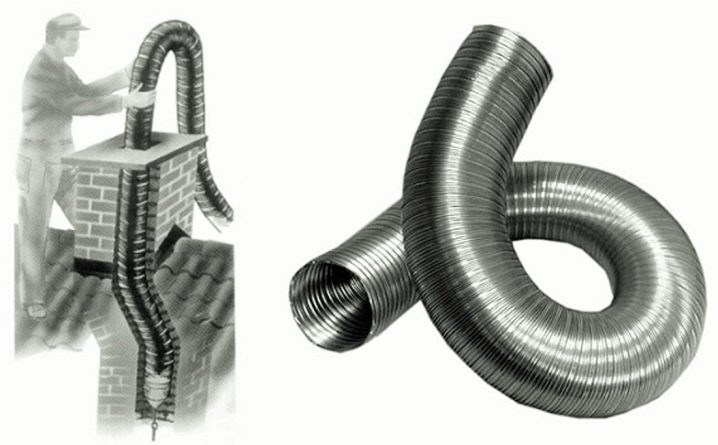

For chimneys, a special corrugation can also be used. It allows for flexibility and strength. Corrugated pipes are perfectly guided through walls and ceilings. They are also used when restoring chimneys from bricks of an indirect type. Typically, the sections are 0.65 m long, but they can be extended up to 3 m.

The corrugated channels are sealed. During development, the joints are not welded or sealed with sealants. This reduces the risk of carbon monoxide and other waste getting outside. Condensation is unlikely to occur. It is worth considering, however, that thin walls can quickly burn out, and the structure itself needs additional insulation; in some places, the use of aluminum corrugation is completely prohibited.

Speaking about chimney components, you cannot bypass the side of the box (they are also casings) for chimneys. Such solutions prevent destruction of the pipe structure and unnecessary wear. A weather vane and a chimney are also important. Fans are often used in chimneys.

Such components activate flue gas evacuation and reduce unpleasant odors when burning various fuels.

The already mentioned simple deflectors are a private version of forced ventilation. However, they are ineffective when the weather is calm (calm).These smoke fans are heat-resistant electrical apparatus. They are placed directly on the chimney. The operation of the device is provided when connected to a home power supply; the shape of the device adapts to the characteristics of a particular chimney.

Choice of design

Brick chimneys are traditionally used. But it is important to understand that not every type of ceramic brick is suitable for this purpose. It is preferable to use specialized refractory specimens. Designs made from them can fit into the interior of any home and complement the visual decor. A brick chimney can be combined with wood heating, that is, with most stoves and fireplaces.

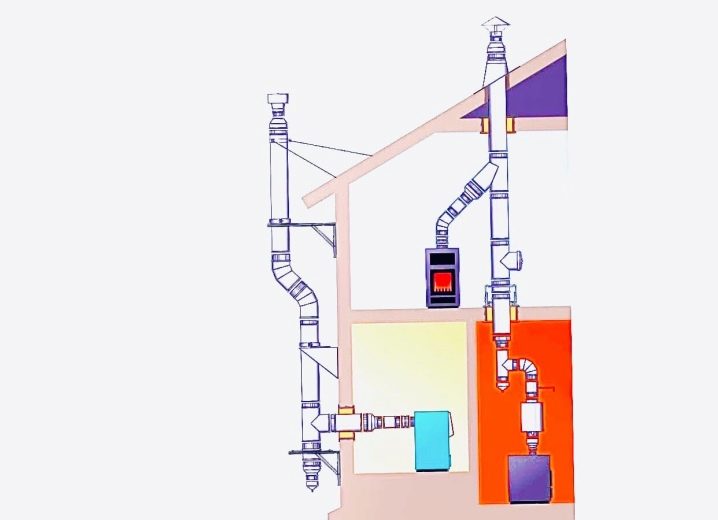

Gas boilers are mainly equipped with chimneys made of first-class stainless steel welded in an inert gas. Mostly they are categorized as "sandwich" in terms of structure. Preference should be given to steel AISI 304 or 316. Modular assemblies do not need a foundation and can be used regardless of the type of fuel (even if it is changed). It is better to keep the geometric shape of the smoke channel as simple as possible.

Closed gas boilers usually involve the use of coaxial chimneys, that is, shortened double pipes. Air enters through one part of the passage, and flue gases move through the other. Such a solution is still rare in domestic practice. If the boiler has an open flame, then atmospheric structures are used, designed only to discharge smoke to the outside. But they have several private options.

First of all, "aspirated" is divided into completely straight and containing various knees. By the type of location, they are:

-

located inside buildings in public places (no insulation is needed, but the risk of fire is higher);

-

placed inside the wall (a completely invisible structure, but not suitable for all chimneys and difficult to create only at the construction stage);

-

fixed outside the dwelling (inside them the place is not occupied, the danger of fire is reduced, but the likelihood of aggressive external influences increases).

How to install it yourself?

Payment

Determination of the diameter and other dimensions of chimneys in professional practice involves the calculation of dozens of formulas. They analyze the physical and chemical subtleties of fuel combustion, the nuances of the geometry of rooms and heating devices, meteorological statistics and some other factors. Such calculations with sufficient accuracy can hardly be done independently. Fortunately, rough estimates can be carried out in other ways.

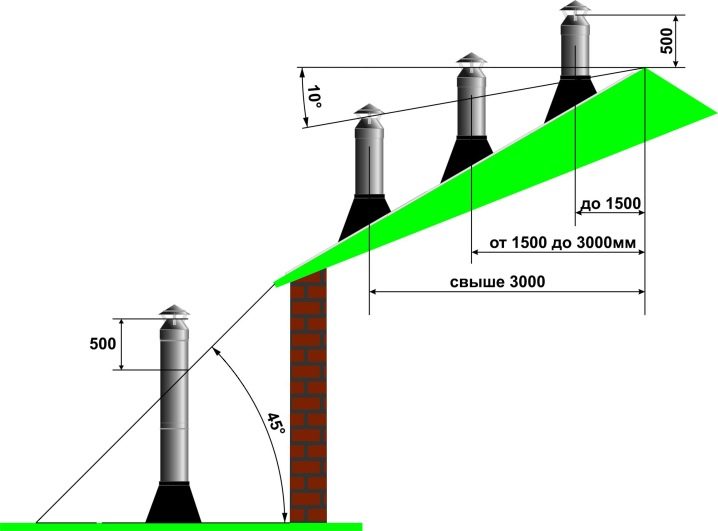

If there is more than 3 m between the chimney and the ridge of the roof, then the highest point can be set below the ridge, but the angle of inclination is no more than 10 degrees.

This solution is optimal from the point of view of saving on parts of the chimney. If the distance is 1.5-3 m, then the channel should be equal to the full height of the house. With an even closer approach to the ridge, the upper level of the pipe rises above the ridge by at least 0.5 m. The chimney section is determined in accordance with SNiP. When you get an inaccurate figure, it is better to increase it - this is more reliable.

Mounting

Correct installation of smoke ducts must comply with the requirements of SNiP 41-01-2003. The total cross-sectional area must be at least the same as that of the boiler nozzles. Thermal insulation is recommended at intersections of roofs and walls. The supporting element in such cases is the mounting platform. It is mainly made from a stainless alloy.

Connections of parts must not be installed between floors and in attics. Contact of the smoke channel with any kind of communications is unacceptable. Flue lines can be bent quite well. But the bending radius must be determined individually, based on sensible calculations. Sometimes it is necessary to fix the chimney to the wall at a distance - it is usually fixed with clamps.

Clips or clamps are selected taking into account the structures to be installed. It is impractical to put the sandwich pipe as the first element. It is better to place the adapter first when setting up. Installation goes from bottom to top, element by element. Preferred assembly "by condensation", when water will flow down the wall inside and will not accumulate.

It is imperative to take into account the requirements of fire protection. All joints must be carefully insulated. Smooth surfaces should act as a support, even small roughness of which is unacceptable. The protruding parts of ceramic channels are often lined with bricks or blocks, which makes it possible to achieve an attractive appearance and protect thermal insulation.

The ceramics are mounted as carefully as possible so as not to split anything.

They begin to create a brick chimney from the layout of the nozzle pipe. Its size is small - 5 or 6 bricks are enough. Such a pipe is predominantly rectangular in shape. This is followed by a thickened fluff. At the end, they put a cap or an umbrella.

Stainless steel structures are mounted from the bottom up. Points of mismatched sections are sealed with a heat-resistant sealant. Its functional temperature must be at least 1000 degrees. The joints of all elements are fixed with clamps. The connecting pipes are fixed so that there are no deflections.

The rise of the chimney above the roof, even in the most favorable conditions, cannot be less than 0.5 m. Installation of nozzles on chimneys is allowed. But they must not interfere with the movement of the smoke. When arranging a roof made of combustible materials, installation of spark arresters is recommended. The groove must be at least 70 mm thicker than the ceiling.

The nuances of care

Chimneys need to be cleaned systematically. It is usually advised to do this every 3 months. More frequent cleanings are practiced as needed. If possible, this procedure is entrusted to specialists. The high temperature sealant should be visually inspected periodically and renewed if necessary.

It is possible to increase the thrust by eliminating errors in the installation and design of pipes, refusing to use too long horizontal sections.

It is useful to increase the height of the smoke channel (within reasonable limits). Sometimes you have to use smoke exhausters. If back draft occurs, it is advisable to use a rotary turbine. In some cases, there is a different answer to the question of what to do - installing a deflector or stabilizer. These designs provide a constant flow.

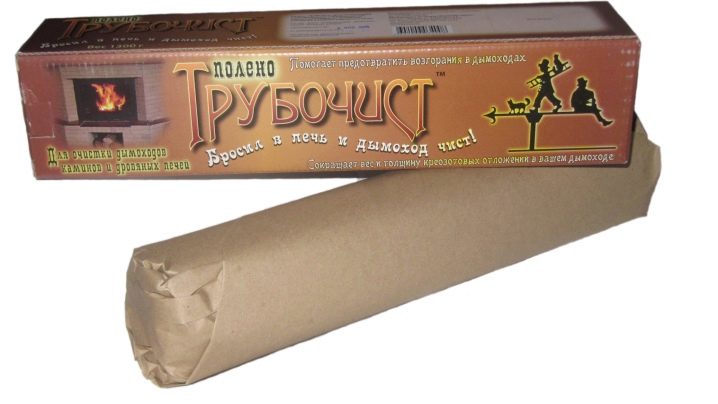

Returning to the cleaning of chimneys, it is worth pointing out that the use of cables is not the only solution to this problem. In many cases, it is more convenient and more correct to burn aspen firewood. They effectively remove even thick soot layers. Sometimes they buy special reagents for the same purpose, such as the "Chimney sweep" log. But the most effective option is considered to be the use of brushes on thick long handles.

The comment was sent successfully.