Mortise locks for wooden doors: description and installation

Often, solid wood models are used as doors to enter residential apartments. They are quite durable, retain heat well and protect the room from excessive outside noise. In 90% of cases of unauthorized entry into a home, it is not the doors themselves that break open, but the locks. Based on this, it is more advisable to purchase a good mortise-type lock for an existing wooden door than to change it to a steel model.

Characteristic

Locking mechanisms on doors are mounted in three ways, by which the models of locks are divided.

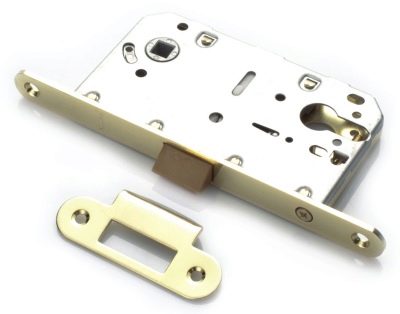

- Mortise. The locking device is mounted directly inside the door body. It is the most versatile and safest type of locking device.

- Overhead.

- Hinged.

In our article, we will focus specifically on mortise locks. To begin with, let's consider the advantages of using mortise devices.

- The mechanism hidden in the body of the door complicates unauthorized access to the lock cylinder and bolts.

- Protection of the lock mechanism from dust and debris.

- Keeping the appearance of the door intact, which is especially important for products finished with valuable species of wood. From the outside, only the lock hole and the doorknob are visible.

Disadvantage: the mortise lock can be installed in the door only once, if the mechanism breaks down, you will have to replace the door or carry out its overhaul, reworking the niche for the lock device.

Views

The most common types of mortise locks for wooden doors are:

- cylinder - the most reliable and affordable models for installation;

- leveler - are distinguished by a high degree of resistance to burglary;

- code;

- electromechanical.

Systems based on rotary cylinders are distinguished by their reliability and the ability to resist burglary with a master key. In addition to these advantages, high-quality cylinder locks have a very large margin of safety and durability. Also, the ease of fastening and the uniformity of the size of the lock cylinder contributes to its quick replacement in case of breakage or loss of the key. Cylinder locks are small in size. The durability of the cylinder mortise lock is achieved through the use of brass guides and a high-strength drive.

Lever locks are the second most popular. The mechanism is based on the use of several levers - special code plates that are displaced only with a key with a suitable profile. Lever mortise locking mechanism perfectly resists force opening and shearing of the locking bolts. Models are also produced with the possibility of recoding - this is very convenient, because if you lose the key, you will not have to dismantle the entire locking mechanism. The conversion procedure itself, when carried out by specialists, takes only 5-10 minutes.

Combination locks are mounted as follows: the main part of the mechanism is placed inside the door body, and only the code plate with numbers remains outside. Constipation opens with a pre-set digital combination. From the outside, such a locking mechanism cannot be disassembled. This type of locking device is often used in offices and manufacturing plants. They are also common as locking mechanisms for access doors in multi-apartment high-rise buildings.

In addition to the above types, hidden locking mechanisms with electrical or electromagnetic elements are used to lock wooden door structures.The mechanism is cut into the door body and connected to the command board. The main condition for the installation of a mortise blocking device is a good masking of its location. Electromechanical blockers are often combined with a cylinder-type mortise lock.

In addition to locking mechanisms, combined locking devices with a power-operated locking bolt drive can be cut into a wooden door. These types of locking mechanisms require an electrical cable connection. When current is applied to the solenoid coil, the bolt connected to the core is pulled into the mechanism and the door is opened.

In the absence of electric current, the crossbars are in the grooves and the door is closed. That is, if you cut the cable supplying the lock (in case of unauthorized entry), the mechanism will not unlock. Only the native key can help here. If you lose it, it is not difficult to replace the lock cylinder. Such locks cannot be opened with a master key, because a burglar will not be able to predict the behavior of the mechanism to shift the cylinder.

How to choose?

When choosing a door lock, first determine which door you need it for. For an interior door, it is better to choose a simple mortise lock or a latch-retainer. For entrance doors, you can choose both an overhead locking mechanism and a mortise, but here the security of the home begins to play an important role. That is, for the doors of apartments, houses, it is better to choose a mortise locking device of a higher security class. These are cylinder, lever models, as well as electromechanical, combination locks.

On the interior doors, you can put both a simple latch and a full-fledged lock with a deadbolt and a latch. If you've chosen a latch-only lock, keep in mind that they come in mechanical, magnetic and latch-type. Latch latches open and close the door under the action of the handle. Magnetic catches keep the door closed by magnetized elements that attract each other.

Crossbars in locks also differ in shape: they are straight and hook-shaped. The first type is used for swing doors, the second - for sliding door structures, to counteract unauthorized movement of door leaves. Table of comparative characteristics of locks of different security classes.

Lock device class | Security level | Detachment action, not less, N | Minimum time of unauthorized opening, minutes | Scope of use | ||

Hasp and bar of constipation | Locking mechanism | The joint of the front plate with the body of the mortise product | ||||

I | Small | ≈2940 | ≈785 | ≈785 | ≈1-3 | Ancillary and doors between rooms. |

II | Normal | ≈2940 | ≈785 | ≈785 | ≈5-10 | Doors for entering residential apartments. |

III | Elevated | ≈4900 | ≈1500 | ≈1960 | ≈10-15 | Doors for entering residential apartments, non-residential premises where cash, material values and / or taken for protection are stored. |

IV | High | ≈6860 | ≈1960 | ≈4900 | ≈30-40 | Doors for entering residential apartments, non-residential premises where funds are stored, valuables of a material nature and / or taken into custody. |

Installation

The procedure for installing a mortise lock of various subspecies is almost the same. First of all, select the set of tools you need to cut the lock.

- an electric drill with drills of suitable dimensions or a milling device;

- pencil for marks;

- chisels (narrow and wide);

- screwdriver and screwdriver;

- hammer;

- measuring device (tape measure, ruler, etc.);

- screws (screws, screws).

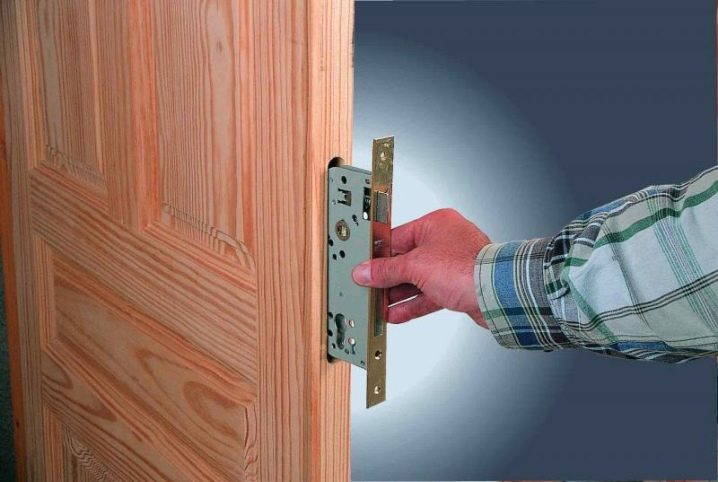

Find a convenient location for the lock mechanism, usually it is cut into the door at a height of 1-1.1 m from the floor surface. Having attached the lock, mark the location of the mechanism and the striker on the end face of the door and the jamb. If you have a milling device, your task of cutting a lock slot will be greatly simplified. The quality of the work done will also increase, at the same time, the likelihood of damage to the door body will decrease.

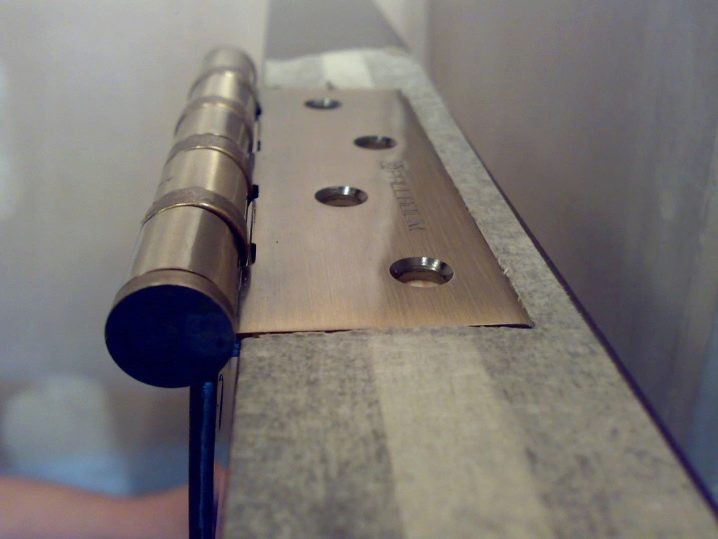

Remove the door from the hinges (if it is already hung on them), turn it face up and lock in this position. The location of the future castle is marked with two strips of scotch tape (painting). Insert a cutter of the required size into the milling device and adjust the penetration depth into the door body. Then make a groove. If you have an electric drill, then drill two indentations along the upper and lower marks to the depth and width of the lock structure. This can be done in two ways:

- do not make a deepening at once to the full extent, but gradually, 1-2 cm in depth, move deeper to the desired mark;

- immediately drill a depression of the required size, for this, make marks on the drill with electrical tape or a piece of wire.

Keep in mind that the dimensions of the recess to be drilled must be a couple of millimeters larger than the dimensions of the inserted lock. The body of the mechanism must be placed in the groove together with the front bar without obstacles. Maintain a strict perpendicularity of the drill in relation to the door body to prevent misalignment. Work the resulting groove with a chisel and hammer. Achieve maximum evenness of the groove walls. Then we mark the place of the front plank. Insert the lock into the recess and draw a pencil around the bar. Along the resulting contour, we knock out a small depression with a chisel.

Next, you should outline the location of the well and the handle. Attach the device to the body of the door opposite the recess and use a ruler to mark the position of the handle and the hole of the lock as accurately as possible. Use a drill with a suitable size drill to drill holes for them. Now insert the locking mechanism into the groove and if no discrepancies are found, attach it to the door body with the screws supplied with the device. If you find any inaccuracies, level the groove with a chisel and a file, constantly testing the accuracy of the lock mechanism entry.

The next stage is debugging the functioning of the lock and preparing the grooves for the sliding crossbars and latch. Insert the cylinder of the lock hole, attach it with the screw supplied, test its functioning. If the problem is not visible, secure the door handle and front strip. Cover the latch and sliding bolts with paint, close the door, turn the key so that traces from them are imprinted on the door frame. Cut out the grooves for the latch and crossbars, trim the edges with a chisel. Hollow out a recess under the striker. Attach it with the screws included in the lock kit.

Check the operation of the lock - turn the handle, turn the key back and forth several times. If the lock works without strain, there are no distortions anywhere, then everything is in order. If you find any flaws, work a little with a chisel and file to align the location of the locking mechanism parts. As you can see, self-installation of the mortise model of the lock into a wooden door is quite simple and is quite within the power of everyone. To reduce the likelihood of malfunctions due to inaccurate procedures performed, test the functioning of the mechanism at each stage. Remember that accuracy and thoroughness in work is half the battle!

For information on how to install a mortise lock for wooden doors, see the next video.

The comment was sent successfully.