Locks for wickets and gates made of corrugated board

To protect the private area from uninvited guests, the entrance gate is locked. This, of course, is understandable to every owner, but not everyone can independently decide on a suitable lock for installation on corrugated board. In fact, there are no particular difficulties here, as well as with the installation of a suitable type of locking device. Just take a moment to read this helpful article.

Description of species

The most popular modifications of locks for street gates are mortise and overhead. The difference between locks for entrance from the street and door options for rooms lies in the narrow strip and the minimum distance from it to the heart of the mechanism. The locking mechanism differs in type.

- Mechanical. It closes and opens as a result of the direct action of the key. Use and installation are not difficult, the lock is not so difficult to repair and replace with another one.

- Electromechanical. According to the principle of operation, such a gate and wicket gate differs somewhat from typical mechanical counterparts. The main difference is the ability to block the input part remotely, using a button on the remote control. By the type of installation, the products can be overhead or mortise. The latter option is safer, since the design of the locking mechanism is inaccessible to outsiders.

- Electromechanical. It can be single or double-sided, but the primary difference is in the drive system. For installation on an entrance gate, an all-weather lock with an external type of fastening, resistant to the whims of nature, is preferable.

- Code. Triggered when the encoded information is specified. Some modern versions are equipped with a fingerprint or retina scanner. Such locking products also include remote versions that read radio waves emitted by a transmitter acting as a key.

Which lock to put on the corrugated gate is an individual decision of the owner of private property. This can be the simplest design of the lock or installation with intricate automation with special protection against penetration and fire.

Many factors are reflected in the choice, including financial capabilities and specific tasks.

By installation type

Hinged

The lock of the most elementary design, for self-installation of which, only steel lugs are required to hold the shackle. Locking is done with a key. But such a lock is easily knocked off by being hit by a heavy object. Another significant drawback is the possibility of locking the gate from the street side. To close the sash from the inside, you will have to equip a bolt or latch.

Modern types of padlocks are made from various metals.

- Cast iron. They are distinguished by their low cost, increased strength and resistance to corrosion. Not suitable as outdoor castles in areas with severe frost. At low temperature conditions, cast iron loses its strength.

- Aluminum. Lightweight products, but at the same time prone to deformation even from small forces.

- Steel. Strong and durable metal. Resistant to all weather conditions. It is more expensive than the previous two options.

- Brass. They will be distinguished by their resistance to corrosion and high cost. At the same time, the locking products are soft and impractical.

They are open, semi-closed or closed by type. If you plan to install a closed lock, the eyelets will have to be ordered taking into account individual parameters. Of the advantages, it is worth highlighting the fact that these devices are distinguished by mobility, and it is possible to choose a product by size.

On average, a padlock can withstand 100,000 operating cycles.

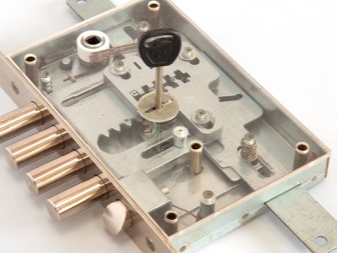

Mortise

Installation is quite laborious. Outside, the door in the fence is locked with a key, and from the inside with a small lever.

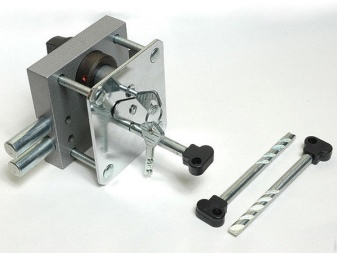

Overhead

A reliable type of construction, but only partially protects against burglary. The mechanism is located from the side of the house, only a turnkey groove is visible from the street.

An overhead lock can be mounted without problems, and there is no need to damage the surface of the corrugated board.

By type of locking mechanism

Suvaldny

It is considered reliable against hacking. Plates with shaped grooves are mounted in the body, which become in a given position with a turn of the key, allowing the bolt to open the gate or lock it. The disadvantages include the fact that most models are large-sized, and therefore the installation of such a lock on a corrugated board is problematic. As for the level of reliability of such a lock, this is directly influenced by the number of levers.

Lever locks are divided into such.

- One-sided. Closing from the street side is done with a key, a handle is installed from the inside.

- Bilateral. They can be opened from either side with a key.

Rack

Reliable locking mechanism with 1-2 bolts, resistant to low temperatures and damp weather.

Cylinder

The design and quality of the core directly affect the reliability of the mechanism. The more complex the core device, the higher the cost of the lock.

In the event of a breakdown, dismantling of the entire device is not required. You can simply replace the core.

Code

To unlock doors with a combination lock from the outside, you need to enter the correct combination of numbers. Locked and unlocked from the inside with a latch. Ensures high level of protection. As far as encoding is concerned, there are options. The first is by pressing the numbered buttons. The second is the introduction of certain combinations on movable digital disks.

The complicated organization of entry and exit to the territory makes the disk lock the most reliable outdoor option. The variation in combinations depends on how many disks are installed. The reliability of the button device is lower due to the fact that from the constant pressing of certain buttons when entering the code, the coating is gradually erased, and it becomes obvious to unauthorized persons which combination is correct.

Electromagnetic

Configured to open with a key that emits an electromagnetic field. To unlock the gate, you need to bring the key to the sensitive field. The principle of operation of this lock is not too specific. With the correct code entered, the bolts move, opening the shut-off valves. The presence of a return spring in the system moves the stem to the locked position.

Radio wave

Manufactured to order. The lock is designed in a similar way to a car alarm. Today, this type of locking device is considered the most reliable. It is virtually impossible to open it without specific knowledge, skills and expensive equipment. The downside lies in the fact that you cannot save on the installation of such a mechanism.

For trouble-free operation, it requires customization, real professionalism and specific tools.

Which one is better to put?

Most often, a mortise lock is chosen for thin metal gates. To put a private area under reliable protection, you need to carefully choose the appropriate option, taking into account the width of the doorway, the depth of the case and the width of the front plate of the lock. The lock, fitted on the outer part of the wicket, will have to be operated in conditions of different temperatures and high humidity, therefore it must meet a number of criteria:

- rust resistance;

- compact size;

- extremely closed design.

An open type of structure will quickly break down due to dust and natural precipitation getting inside. A large-sized lock is not suitable for installation on thin metal, since when erecting such a fence, profile pipes with a small diameter are used.

Massive locks are more suitable for heavy metal gates.

Leveler mechanisms work best in case of temperature drops, with increased dampness and dustiness. But even the highest quality and most expensive castle has a chance to freeze when moisture enters the larva in low temperature conditions. To avoid difficulties with the passage to your territory, it is recommended to install the devices with a handle from the inside, which are unlocked without using a key.

There is no need for multi-level protection against burglary in relation to locks for doors made of corrugated board in a summer cottage. Such costs are useless. If someone decides to enter your courtyard, then the castle, probably, will not touch, but will find another way to get into the territory.

Electromechanical or electromagnetic devices are installed on thin corrugated doors, if the entrance structure requires it. And more elementary modifications can be cut-in type or overhead. The installation of these mechanisms is quite different.

An overhead lock is the easiest to mount.

A security class is defined for each locking mechanism, providing a level of protection against burglary. Determine 4 degrees of reliability.

- This category includes locks, which are not difficult to open for someone who has criminal intentions. An experienced thief will handle this lock in a few minutes.

- An inexperienced thief will spend some time opening such a device. A seasoned robber can easily open this lock. According to experts, it will take no more than 10 minutes for a thief to break into a device of this class.

- Locking mechanisms with a reliable degree of protection. They cannot be opened in less than 20 minutes.

- The most reliable of the existing ones. According to the assurances of the manufacturers, it will take about half an hour for hacking. This time will be enough for the security service or law enforcement officers to arrive at the scene of the crime.

It is better to choose locks for the entrance parts of external fences in specialized stores.

The help of a consultant will help you decide on the most convenient modification.

DIY installation

After the desired lock is purchased, you will need to install it. This requires the following inventory:

- fasteners;

- angle grinder - angle grinder;

- electric drill;

- drills for metal;

- simple pencil;

- screwdriver.

If the lock is to be installed at the entrance of a hollow structure, you can start the process by marking the zone for the mortise lock at the end of the wicket. Cut a niche of a suitable size, drill grooves for the bolts in the canvas, and also make holes for the handle. At this stage, the preparatory stage is considered completed.

Hinged

To hang such a lock, in addition to those listed in the list, you will need to prepare 2 corner lugs, bolts and nuts. The installation process includes the following steps.

- A place is selected for installing the lugs. They should be fastened in one line, but at a short distance, in order to eliminate interference with the gate gate and difficulties in mounting the lock.

- Fasteners are applied to the canvas for visual marking of the holes.

- Drill holes using drills of the required diameter, based on the size of the fasteners.

- The lugs are fixed on the metal profile.

Overhead

The situation with the installation of such a lock is a little more complicated. The overhead lock is attached to the corrugated hinged doors in the following sequence.

- The locking device leans against the gate from the side of the yard so that one of the fastening grooves goes onto the cross bar, and the handle with the larva is slightly higher (lower).

- The holes for the bolts are marked and a groove is made for the deadbolt. If the post next to the wicket is round in configuration or of small diameter, you will have to weld a plate on top for the counterpart of the lock.

- Mounting holes are made in the frame of the wicket, and grooves for a key and a handle are cut in the profile (when planning). Then a groove is cut out in the support element for the crossbar.

- The device is fixed with pads and handles.

When it is not possible to fit the lock on the cross member, it is placed on an additionally welded metal plate.

Mortise

It is more difficult to insert such a lock yourself, but it is quite possible if you proceed as follows.

- On the frame, you need to mark the location of the future device.

- Use a grinder to make a hole in the pipe.

- Lean the lock and mark the areas for the fasteners, then drill them out. Insert mechanism.

- Make a hole for the key in the profiled sheet.

- The lock striker must be correctly positioned on the support post. The level of its location is primarily determined.

The frame can be made of different materials, which determines the procedure for installing the strip.

- Narrow metal. A plate of 3 mm thick is welded onto the support, then grooves for the bolt are drilled in it.

- Larger pipe. The hole is drilled at the point of contact between the crossbar and the support post.

- Metal corner. If it has a wide part, then a slot is made in it. On a narrow element, it is necessary to build up a metal plate with pre-drilled holes for fastening by welding.

For a longer service life of the installed locks, you need to adhere to some recommendations:

- from time to time, test the device for possible malfunctions: if they are detected, it is not worth postponing repairs, it is important to immediately determine the cause;

- it is advisable to build a visor above the locking mechanism, which will protect the lock from contact with precipitation;

- The operation of the mechanism should be checked every year before and after the winter season, if necessary, lubricate the latch and the core.

Correct installation and operation of the locking device is the key to its long service life.

If you are not sure that you will be able to embed or fix the lock yourself, it is better to entrust this business to professionals.

The comment was sent successfully.