How to insert a lock into a wooden door?

The reliability of metal doors will never replace the beauty and environmental friendliness of wooden counterparts. However, such products have their own characteristics, and they also relate to the installation of locks. You can even do this kind of work with your own hands, if you know how to do it.

Required tools and accessories

Cutting locks into wood canvases requires the use of:

- drills for wood;

- set of steel crowns;

- a set of chisels;

- roulette;

- construction pencil;

- screwdrivers - slotted and Phillips;

- drills;

- screwdrivers;

- hammer.

The selection of the castle plays a very important role. In this case, they are guided by the size of the structure. An excessively thick lock will not provide the necessary weight of the wood on the left and right sides. If less than 1 cm of wood remains there, the door will not be strong enough. Enough of a kick for the whole canvas to crack.

Additionally, it is required to control the depth of the castle entrance. Some of the canvases are thicker on the outside than in the center. The glazed part can also present difficulties. If you have to prepare a place to insert a large lock, it is easy to deform the material. As for the fasteners, they must be selected according to the manufacturer's instructions.

Often it is not possible to get by with a drill or an angle grinder. A hand-held router is considered to be the best tool for cutting locks into doors made of solid wood or other wooden materials. Although “off the shelf” lock tapping kits are relatively inexpensive, professionals advise to select each tool separately. This allows you to finally make sure of its quality (both when buying and renting). In addition, such a solution helps to save money.

Sequence of work

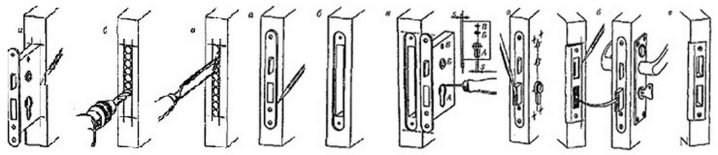

If the product is chosen properly, you need to correctly cut the lock into the wooden door. Begin by applying a constipation to one of the sides, in the right place. With the help of a construction marker, they circle the part - according to the drawn lines, you can finally determine whether the choice of the lock and location is correct. If there are no errors, a position is marked on the end face of the door. When there is a special paper template in the kit, use it.

Take a feather drill, the thickness of which is chosen very carefully. Then, with a screwdriver, passages are prepared, forming a vertically running line. The outer edges of the holes must be mutually adjacent. If the required drill is not available, smaller drills may be used. They arrange holes in 2 or 3 tiers.

Now you need to take a chisel, which allows you to remove excess wood. A slotted screwdriver acts as a replacement for the chisel, but such a tool is not convenient enough. Then they insert the product into the prepared place, circle the end strip with a marker and pull out the closing part. 0.2 - 0.3 cm of the tree is removed strictly according to the line. This will allow the lock to deepen into the door, flush with the bar.

This technique is practiced when installing locks in order to exclude the beating of the strip on the surface of the box. If the gap is large enough, you can skip this step. The next step is to mark on both sides of the place for a key hole or for a lock cylinder. If the design has handles, marks are also made for them. The lock is pulled out, drilled in the marked places.

Now you can insert the lock back, evaluate the correctness of the prepared holes. The larva (if any) is fixed with a screw from the end.Next, insert a square base from the handles, screw the handles themselves. The key is inserted, the operation of the lock is checked immediately. Opening and closing should be easy, without rubbing the key against the wood.

Then the time comes to mark the holes for the transom elements and the striker. The easiest way to do this with your own hands is using a paste. When the door is fully open, the lock is locked, and the end part of one or more crossbars is lubricated. Next, you need to open the bolt, close the door, lock the lock. Normally, it will not lock, however, pasta paths will appear. They will indicate how and where to make holes for the mating block. They are drilled immediately to eliminate errors.

A striker is applied to the holes, a mark is made along its contour with a pencil. With the help of a chisel, part of the wood is removed. This will deepen the bar. It remains to fix it. Now the door is closed, and the operation of the lock is checked again. When everything is working fine, put decorative overlays. Everything, you can enjoy an excellent result. There is nothing complicated about it.

Additional information and recommendations

To ensure an exact match between the actual and planned depth of the holes, tape is glued to the drill. You can select a residual tree with a chisel. Later, the walls are leveled with a chisel. It is necessary to strive for such dimensions of the groove that will allow the inserted lock to coincide with the end face of the door. This means that when gouging the socket, periodic try-ons are required.

To make a curly groove for the keyhole, you need to use a hacksaw. The edges are brought to the perfect shape with emery. Since it is not comfortable for them to work by hand, you can attach the paper to a screwdriver. A thin drill is best. Mounting the striker plate for mortise and overhead mechanisms is no different.

It is recommended to choose a drill bit that is thicker than the lock. Usually a few notches are drilled so that the web filler can be removed. When drilling is finished, use a chisel and chisel to remove excess dust. But all these rules may turn out to be useless if you do not follow one more principle: as soon as something is measured with a tape measure, you must immediately put a mark with a pencil or marker. It is extremely frivolous to rely on your memory in such a responsible matter.

"Handle" lock insert

This manipulation definitely deserves a separate analysis. Experts recommend to play it safe and glue the end of the door, as well as its plane with masking tape. This should be done to prevent possible damage. As practice has shown, it is much more convenient to put separate marks on the tape. And it will also serve as a well-visible border, which is categorically impossible to cross during work.

It is recommended to place the handles-locks exactly 100 cm above the floor. This kind of constipation should always be supplied with the template. Therefore, there are no special problems in the markup. Since the cylinder mechanisms can be of different sizes, you need to look for a suitable crown only after purchasing the lock. When using a template, they do it like this:

- it is bent carefully along the line of the protrusion of the door;

- applied from the front side;

- make marks showing the centers of the holes.

In these places, a hole is drilled in the plane of the door. It is inappropriate to punch through it. As soon as the pilot drill comes out from the opposite side, pause and start drilling with a crown from the wrong side. This approach is really professional and avoids wood splitting. Then it's time to prepare the holes for the latch.

At the same time, work on the marked places with a pen drill 2.3 cm. You need to go to the previous hole. The drill is held strictly at a 90 degree angle to the door. Otherwise, there is a great risk that the latch will jam and work poorly. When the passage is ready, the latch is inserted into it.

Now you need to align the position of the element in relation to the edge.A pencil will help you trace the outline of the decorative frame. Further, removing the latch with a stationery knife, the canvas is cut along this line. When this work is done, a secret cavity is selected using a chisel, which should be slightly smaller in size than the latch frame. It is impossible to initially clean the cavity, this may result in damage to the film with a chisel.

Having prepared the groove, they return the product to its place, pulling the latch with self-tapping screws. The holes for them are drilled in advance with a 2 mm drill. If the part moves tightly, it is necessary to undercut the contacting places. The assembly of the handle itself is done according to the manufacturer's instructions. It is imperative to pay attention to how the tongue is located (normally, it always looks inside the room).

For information on how to embed a lock into a wooden door with your own hands, see the next video.

The comment was sent successfully.