Making a jack with your own hands

The jack is a popular tool that almost every car enthusiast uses. The unit allows you to cope with almost any, even the most unforeseen situation, and helps to quickly fix the breakdown. The jack should be in the car in case there is a need for repairs, and there will not be a single settlement or car service nearby.

It is not always possible to purchase a quality jack. Therefore, if necessary, you can do it yourself. It is important during manufacturing to ensure the required level of safety of the future device. It is worth taking a closer look at how to create a jack.

Device

The main task of the jack is to lift the wheels of the vehicle for their subsequent replacement. The tool is used both for professional repair work and for DIY home wheel replacement. Through the operation of the jack, repair work is also carried out in certain compartments under the car, ensuring that the machine is lifted.

It is noteworthy that the jack is popular not only in the automotive field. It is used to install various structures and when carrying out construction work or repairing various equipment. There are the following types of jacks:

- Mechanical. Lifting is carried out by pressing the lever on the handle. They are not used very often, but they are compact and lack physical effort.

- Hydraulic. A distinctive feature of the tool is the principle of its operation. The lifting of the wheels is provided by the incoming pressure created by the working fluid. Such jacks are popular.

- Pneumatic. Compressed gases are responsible for the operation of the device. The chamber is increased by means of the generated pressure, which makes it possible to raise the car.

If desired, you can make any of these jacks using the appropriate tools and materials. Homemade jacks are popular too.

Material selection

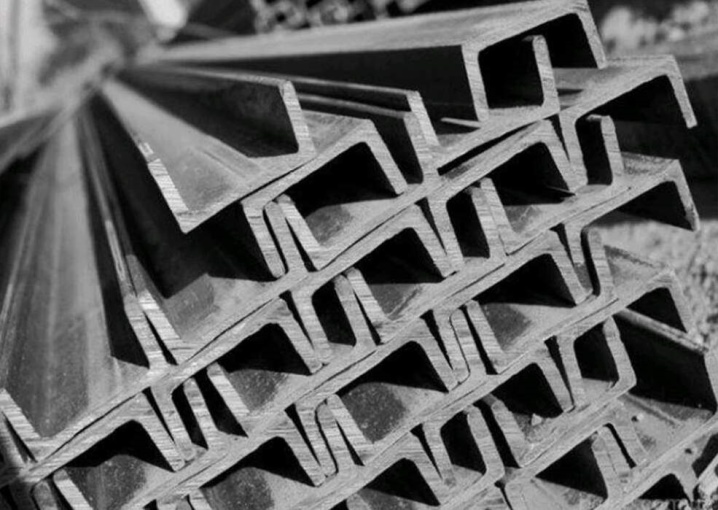

The main thing that needs to be provided in a homemade structure is to achieve its strength. Therefore, for the manufacture of the frame, materials such as:

- steel channels;

- profiles from PVC pipes;

- metal rods from profile steel;

- wheels that move the object;

- rubber part for the bowl;

- fasteners.

Required tools

As the main tools and materials you will need:

- welding machine;

- grinder equipped with grinding and cutting wheels;

- drill;

- set of tools.

Also, there should be a tape measure, a ruler and other measuring instruments nearby. Additionally, it is recommended to prepare a marker so that measurements can be marked.

How to make

If you wish, you can make almost any jack with your own hands. Therefore, it is worth considering in detail what is needed to create a specific model.

Hydraulic

The most common type of lifting tool. It has a high carrying capacity, so it is often used during the repair of trucks or SUVs.

The design of the device includes:

- frame;

- butter;

- piston.

The body of the device comes in different shapes and lengths.The best option for the manufacture of the unit would be to use hardened steel, which will provide the necessary strength.

There are several holes in the body. They provide:

- pull-out cylinder;

- lifting lever.

There is also a T-shaped handle that allows the elements to be ejected. The movement of the device is facilitated by polyamide wheels, which provide great opportunities for maneuvering.

You can assemble a hydraulic jack with your own hands in a few hours. To create a device, you need to prepare:

- welding machine;

- hacksaw;

- a machine equipped with a grinding disc;

- steel profiles.

The assembly of hand-held equipment is carried out in several stages:

- First you need to make a support platform. The mechanism of the unit will be located on it. To create a platform, it is necessary to cut 4 parts 300 mm long from a rectangular profile, the cross-section of which is 50x50 mm. The parts must be laid out with the walls to each other and welded to ensure their fixation.

- Next in line are stops and stands. To make them, you will also need to cut 3 parts from the steel profile. In this case, for the stops, you must first calculate the length, and the length of the rack should not exceed the width of the support platform. The connection of the elements is ensured by welding.

- The last stage is the manufacture of a convenient removable stop, which ensures the transfer of pressure to other elements. To create a part, you will need several pieces of steel strip, the thickness of which should not exceed 3-5 mm. The length of each stop must be equal to the distance that is formed between the struts of the structure. Installation and fixing of the stops is carried out by welding and fasteners.

If required, the distance that forms between the stop and the beam can be reduced.

Rack

Before making such a tool, it is recommended to pay special attention to strength indicators, since the stability of the future jack depends on them. That's why it is important to assemble the device so that it does not fall anywhere and does not leave during operation.

Self-production of such a jack does not require much effort. The procedure will not take long. For manufacturing, it is necessary to weld two steel slats to each other at an angle so that they form a pyramid with a truncated end - a trapezoid. This will be the support of the structure. Then you need to make two bases of the mechanism - above and below. A steel sheet with a thickness of up to 5 mm is suitable for manufacturing.

The third step is to provide the bases with holes for welding the nuts. A hole is also made in the bottom base, where a mechanical rod must be installed to ensure rotation. Additionally, you will need to make a knob.

The mechanism is recommended to be made of steel parts with high strength indicators. Additional attachment of a metal cable to the rack and pinion jack will help replace the winch.

Trolley

A bottle jack, which is a simple design, is taken as a basis for manufacturing, and its alteration is performed. The lifting height of such a unit is 23 cm, which makes it possible to lift trucks.

Bottle jacks activate the working rods during operationto lift the machine using the provided lever. The lever is driven by a hydraulic cylinder installed in the structure.

The garage jack is assembled in several stages:

- First, a rack is made using a 12 channel.

- Next, the assembly of the lifting mechanism and the base takes place. To do this, you need to use a 10 mm channel.

- In the front of the structure, rollers are mounted. The standard ones found in washing machines will do.

- To make a jack cup, you can take an element of an automobile bump stop.The braces are made from rods, the diameter of which does not exceed 20 mm.

Judging by what the structure is assembled from, the principle of operation of a rolling or scissor jack is similar to a bottle jack. The only difference lies in the axis along which the cylinder moves. In the updated unit, it is made horizontal. The tool got this name due to its appearance. It resembles a cart on wheels.

Screw

The screw jack design includes the following elements:

- base;

- two shoulders;

- emphasis;

- mechanism in the form of a screw.

The assembly takes place on a steel sheet base with a cross-sectional area of 2.63 cm2. 4 holes are drilled in the corners of the base to install fasteners that will fix the base.

For the manufacture of the rotation shaft, metal rods are taken, the diameter of which does not exceed 12 mm. It is important that there is a thread at one end of the element and a retainer at the other, which provides the ability to secure the pin.

In the last turn, an axis is made, which ensures the rotation of the shoulders - upper and lower. Additionally, pins equipped with flat cylindrical heads are installed on the sides. For fastening the elements, cotter pins are used. The installation of the retainer completes the process.

Pneumatic

This is a jack, which is designed with a pneumatic cushion. Tool making does not take much time and effort. In addition, the design drawing of the unit is interesting, which will make the assembly unusual.

With the help of powerful jacks, precise installation is carried out, so the unit is popular in many areas. The shell is flat and forms the basis of the device. During operation, compressed air is supplied to it, providing an increase.

To create a mechanism, you need to prepare:

- a pillow used in trucks;

- ball for bearing;

- a bolt from a VAZ wheel;

- fasteners;

- drill.

The procedure is carried out in several stages:

- First, fastening bolts are mounted in the provided holes of the pillow. Each bolt is pre-drilled.

- Next, a hole is made in the VAZ wheel bolt. It will be used as a valve.

- The third stage involves the connection of all elements. The outlet is closed with a ball, which will prevent the ingress of air currents during the operation of the unit.

To use the attachment, you need a pump. The unit should be located under the underside of the machine. Additionally, so that the device does not budge, you need to prepare a block.

Electric

The last version of a homemade lift. A distinctive feature is the complexity of making such a device with your own hands, so not every master will decide to use this option.

An electric type jack combines:

- lever mechanisms;

- electric drive.

For the manufacture of such a jack, you can use the motor for the power windows. In this case, it is recommended to remove the drive and cables from the structure, leaving the gearbox and motor inside. Additionally, you will need to prepare a head and a screw jack, which will be used as a basis for creating the case.

The purpose of assembling the electric jack is to prevent the need to create any physical effort while using the device. The jack can be fastened from steel strips of medium thickness, which must be trimmed beforehand. The strips are fixed by welding.

Recommendations

Only the person who made it is responsible for how a homemade garage jack works. So anyway, no matter how confident the creator of the jack has, it is recommended to use insurance - another lifting devicewhen it comes to carrying out repair work on the engine or pallets under the vehicle body.

The jack is a popular tool for lifting cars. Therefore, if it was decided to assemble the unit with your own hands, you should approach the matter responsibly.

How to create a rolling jack, see the next video.

The comment was sent successfully.