Features and varieties of telescopic (two-rod) jacks

The jack is considered an indispensable tool not only in professional car services, but also in garages of motorists. Despite the huge selection of this device, telescopic models designed for carrying capacity from 2 to 5 tons are in special demand. They are presented on the market in several types, each of which has its own technical characteristics.

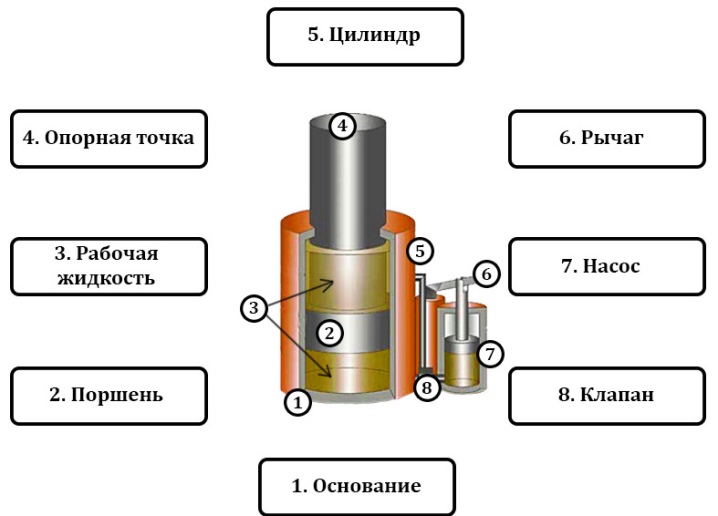

Device

A telescopic (double-rod) jack is a mobile device designed to lift cargo and a vehicle during its maintenance and repair. The principle of operation of a double-rod jack is based on Pascal's law. The design of this device consists of two vessels connected to each other. They are filled with hydraulic oil, which, when pumped through a special valve, flows from one reservoir to another, creating excess pressure to lift the stem.

The main feature of telescopic jacks is that they have two functional rods, this provides lifting of the load to a great height.

Double rod jacks consist of the following elements:

- cylindrical tank for storing working fluid;

- a piston that is driven by oil pressure;

- distributor, it is responsible for even distribution of pressure in the right direction;

- a filter that removes small particles and other contaminants from the oil;

- dump and discharge valves designed to maintain a certain amount of pressure and return the stem to its initial position;

- pump responsible for pumping hydraulic oil and maintaining pressure.

Views

Today on sale you can find telescopic jacks of various types - from stationary to portable and mobile. Besides, the lifting device may differ in size, principle of operation and design features. The most common types of double-rod jacks include the following.

Mechanical

Great for car enthusiasts. Its mechanism is driven by the physical efforts of a person. Such a jack is usually diamond-shaped and comes with a sliding mechanism, the main component of which is the lead screw. To lift a load using a mechanical device, it is necessary to turn the handle, while the lifting capacity directly depends on the screw thread (the wider the pitch, the higher the load can be lifted).

As a rule, this type is used to lift a load weighing 2 tons.

Among the mechanical double-rod jacks, rack and pinion models, in which a folding pick-up is fixed on a tripod, deserve special attention. Compared to other mechanical jacks, rack and pinion jacks are available with lifting heights from 500 mm to 1 m.

They are considered the ideal choice for SUV owners and are indispensable for installation work in construction.

The main advantages of mechanical devices include: compactness (they take up little space in the garage), ease of use, good stability, reliability in operation and an affordable price. As for the shortcomings, such jacks cannot be overloaded with an unacceptable weight, and they also have low efficiency.

Hydraulic

This type runs on hydraulic oil. Its principle of operation is as follows: the drive pump creates oil pressure, which causes the plunger (piston) to move and starts the process of lifting the load to the desired height. After the working fluid enters the pump reservoir, the load begins to descend smoothly. The double-plunger jack has a lot of advantages, among which are high lifting capacity, smooth running, high efficiency and mobility of the structure.

Despite the fact that this type of device has a lifting capacity of more than 2 tons (most models can lift a load weighing 3, 4 and 5 tons), the equipment also has one drawback - the lack of the ability to adjust the lowering height.

In addition, hydraulic jacks are expensive.

In turn, hydraulic jacks are subdivided into bottle jacks, rolling jacks and special jacks (hooking, diamond-shaped).

The most popular and functional are two-rod bottle models, they are characterized by a convenient design and a long service life.

The rolling jack has found wide application among motorists, it can be found in any garage. The design of the rolling device is in the form of a trolley with a rigid frame, which is able to withstand heavy loads. In addition, the structure includes a protection valve, it is triggered in the event of overloads and increases the safety of the device.

The main advantages of rolling jacks include:

- full autonomy;

- high efficiency;

- no need to spend time and effort;

- safe and convenient operation (can be used in any place where a breakdown has occurred).

There are no drawbacks to such units.

Manufacturers

Every car owner should have in his toolbox such a versatile and useful device as a double-rod jack. If the purchase is made for the first time, then you should pay special attention to the rating of the models and take into account the reviews about the manufacturers. The following manufacturers of telescopic jacks have proven themselves well on the market.

- Etalon (Russia). This company is well known for its products both in the domestic and foreign markets. Its main direction is the production of hydraulic jacks (telescopic bottle and rolling), which are designed for lifting capacity from 2 to 5 tons. The size of the working stroke of the devices is from 100 to 200 mm. Jacks are ideal both for lifting vehicles during repairs and for assembly and dismantling works in construction.

- Matrix (USA). This manufacturer specializes in the production of trolley type hydraulic jacks with a safety valve, which is designed for a lifting capacity of up to 3 tons. The maximum lifting height of the device is up to 140 mm, and the height to which the load can be lifted is 520 mm. Devices of this brand are characterized by high quality, safe operation and affordable price.

- Kraft (Germany). Products from this world-famous manufacturer are considered the best, as they combine high quality and affordable prices. Most of the models produced by the German factory are hydraulic bottle jacks with a lifting capacity of 2 and 4 tons. The lifting height for each model may be different, but it does not exceed 380 mm. Jacks are additionally equipped with a crank lever.

- Zubr (Russia). This manufacturer produces mechanical (rack), pneumatic and hydraulic double-leaf jacks with a lifting capacity of 2, 3, 4 and 5 tons. All devices from this brand are characterized by high lifting and picking heights, stability, smooth running and compactness.

Separately, you can also highlight such foreign manufacturers as Ombra, Stayer, Stels. Their products were appreciated not only by motorists, but also by the masters of professional auto repair shops.The main product line consists of telescopic hydraulic jacks with a lifting capacity of up to 5 tons.

As for Russian manufacturers, they also hold leading positions in the market. Double-leaf jacks from the Vladivostok and Petukhovsky foundry and mechanical plants are very popular not only in Russia, but also abroad. Domestic manufacturers offer a wide range of jacks with a lifting capacity of 2 to 5 tons, there are also models designed for a weight of 8 to 40 tons.

How to use?

Telescopic jacks are usually used for trucks, cars, buses and other equipment. Thanks to the units, you can quickly and easily raise a part of the car above the ground and replace the wheel and pads.

To ensure the correct operation of the jack, you need to adhere to certain rules for its operation.

- Do not use the device in cases where the weight of the load exceeds the lifting capacity of the tool. This is traumatic and could cause the jack to break.

- Before starting to work with the device, it is necessary to determine the center of gravity of the load that is planned to be lifted. In addition, it is required to choose the most suitable position, only then can the jack be installed in an upright position on a flat and solid surface. If necessary, you must additionally put a lining of hard material under the bottom.

- It is necessary to operate the device from the complete closure of the exhaust valve, for which the end of the jack lever is used. It is inserted into the pump piston socket and pumping is started, after which the piston rises smoothly. When the maximum lift is reached, the hydraulic arm will begin to lock.

- If you rotate the exhaust piston, it will begin to descend. It is recommended to turn slowly to avoid accidents. In the case when several lifting devices are used at the same time, it is very important to ensure that the specific load level is not exceeded, and the lifting speed of all jacks is the same.

- When using a telescopic jack, it is important to take into account the ambient air temperature, if it is from -5 to -20 C, then it is advisable to pour oil into the system that is resistant to low temperature conditions. In addition, it is necessary to constantly monitor the oil level in the piston, if it is not enough, then the required lift height will not be achieved.

- When lifting a load, it is strictly forbidden to be under it, as well as to push various parts of the body under it. Low-lift jacks cannot be used to secure the load at the selected height.

In the next video, you will learn how to choose the right jack.

The comment was sent successfully.