All About Hydraulic Rolling Jacks

The jack is one of the most important tools of the motorist. It should always be included with the vehicle. Currently, an increasing number of car owners are using rolling jacks. Their production and supply became widespread. The goal of the article is to acquaint the consumer with the device and the principles of operation of these devices, to orient him in the variety that the market offers.

Peculiarities

A rolling jack is a type of hydraulic jack. It slides under the car on special wheels, lifts the car with the help of a specially positioned hydraulic cylinder and itself takes the desired position depending on the lift height, that is, rolls up. Hence the name.

It is arranged much more complicated than other hydraulic, and even more so, screw jacks. Consists of the following elements:

high strength steel frame on four wheels, the front of which are load-bearing, and the rear ones are guides;

hydraulic cylinder with a rod that rises with the body;

platform (in common parlance - "patch") - the part that rests against the car when lifting;

delivery pump driven by a special handle (lever).

The advantages of this device include:

stability and reliability;

the ability to keep the car in a raised state for a long time without safety devices;

sparing attitude to the car: does not break thresholds, does not spoil the paintwork;

quickly raises and lowers.

Disadvantages are a continuation of its merits:

requires solid support (floor, asphalt, concrete) and a flat surface;

rather bulky, takes up much more space than a screw;

costs significantly more than its counterparts in terms of carrying capacity of a different design.

Principle of operation

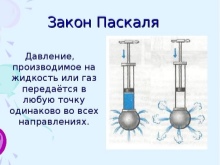

The rolling jack works on the hydraulic principle, which is based on Pascal's law on the pressure exerted on a liquid or gas. The working fluid in this device is hydraulic oil. Pumped by the pump, it enters the cylinder and lifts it together with the housing under load. As you know, liquids are hardly compressed, and therefore a hydraulic jack can hold a raised load for a very long time. Devices of this design, depending on the purpose, can lift and hold from 1 to 200 tons.

The following design features are possible:

lock, a special safety pin that protects against accidental unauthorized lowering;

pre-lift pedal for faster and more precise approach to the vehicle being lifted.

These features make the tool easier to use. But this affects its price.

Such jacks are usually classified as professional and cost a lot of money.

Model rating

Among rolling jacks for passenger cars with a carrying capacity of no more than 2 tons, buyers' sympathies are distributed approximately as follows.

Kraft KT 820000

It is an old German brand of tools and accessories. Manufactured in China. It is considered one of the best in the household segment (for rare minor car repairs). Pick-up height (beginning of lifting) - 135 mm, lifting height - 320 mm. The average price is from 2000 rubles. Supplied in a plastic case.

"Zubr 43053-2-K"

The most common trolley jack made in Russia. Reinforced construction. Strong and reliable. Raises the passenger car to a height of 330 mm. This is sufficient to replace most wheel diameters. Price - from 2300 rubles.

Belavtokomplekt BAK. 00053 "

This brand has been known since Soviet times. Price - from 1600 rubles. Lift height - 320 mm. The price is tempting, but the quality, according to reviews, is sometimes "lame".

Autoprofi DP-20K

Russian brand, rapidly gaining popularity brand. These jacks are reliable and durable. Lift height 330 mm. Suitable for most passenger cars. Price - from 2200 rubles.

Comes with a case.

Matrix Master 51020

The homeland of the brand is Germany, but the equipment is made in China. Lift height 355 mm. Consumers note the convenience, compactness and reliability, ease of use. Price - from 2300 rubles. Supplied in a carrying case.

Titan 20008

Newly emerged Chinese brand. Price - from 2000 rubles, supplied in a plastic case. The price is attractive, but there are complaints about the quality of rubber seals and ease of use.

The lifting height of 360 mm is very tempting.

Of the professional devices, it would be worth noting the Norberg N32035 with a lifting capacity of 3.5 tons. Lift height 558 mm. Price - from 11 thousand rubles.

Such and similar jacks are used in car services and tire shops.

How to choose?

Choosing an automobile rolling jack should be primarily based on the purpose of use. Most motorists need it for ad hoc repairs and minor maintenance. For this, household (or "amateur") jacks are enough, discussed in the "Rating" section. The determining factor here is the price-quality ratio. All of these devices fully meet this ratio and, with some fluctuations in quality, are suitable for any passenger car except SUVs. Bottle jacks or rack jacks are recommended for all categories of SUVs.

Professional rolling jacks are needed to work in auto repair shops. They have a much greater resource, carrying capacity and height.

They cost many times more, but these expenses are necessary.

How to use?

Before using the jack, you need to carefully study the manufacturer's instructions, and take all further actions in strict accordance with it. The recommendations given here have, of course, a very general meaning.

We install the car on a flat surface (without obvious slopes) with a hard surface (concrete, asphalt, wooden floor). If there is no coating, then we put a metal sheet or strong boards.

We roll the jack under the car so that the stop fits into a solid part of the structure (stiffener, spring bracket, cross member of the power unit).

Make sure that the bypass valve on the jack is closed. For this, there is a special groove at the end of the jack lever. We try to tighten the valve, if necessary, tighten it all the way.

We insert the lever into the groove of the hydraulic pump, fix it and start pumping. The working part of the jack rises at an angle, and the jack itself, moving on wheels, takes an optimal position under the load point.

Having raised the car to the required height, we substitute a safety stand (the rolling jack can hold the lifted load for a very long time, but safety comes first) and we carry out the necessary work.

After completing the work, putting in place all the removed parts, we lower the car. It can be lowered by opening the bypass valve on the jack. We release the lever, put it on the valve head and turn it off (¼ turn is enough). The car will lower.

The rolling jack requires care and maintenance. Each time you work with the jack, you need to inspect it for possible oil leakage, monitor the cleanliness of the rod, evaluate how the jack reacts to swinging the lever. At the same time, do not forget to periodically check the oil level and top up if necessary. The instructions usually explain clearly how to fill the jack with oil.

If there are leaks, contamination of the stem, the jack "does not obey" the lever, then it is time to replace the rubber seals. Some (not all) jacks are equipped with a repair kit: a set of rubber rings that must be replaced during maintenance. Replacing them costs some work, but nothing too complicated.

The jack should be stored and transported in an upright position (in which we substitute it under the car). This is to prevent oil from leaking out. In this sense, it is very good when the jack is completed with a case. The location of the jack in it is already correct from the start.

And the last moment. Hydraulic jacks are frost-resistant. At temperatures below -10 degrees, the oil thickens noticeably and is poorly pumped.

Review overview

Despite the "consumer extremism" that has developed in recent years, reviews of rolling jacks on the websites of online stores and in analytical portals are generally positive. The owners note the convenience of using them, the speed of lifting and lowering, the relatively low weight and dimensions, stability during operation and safety for the thresholds and other parts of the car.

Complaints often relate to the quality of rubber seals (most often this applies to Titan jacks), to the length of the lever (too short, you have to make additional efforts), to the weakness of the frame, which bends under load ("Belavtokomplekt"), to the problematic drive of the hydraulic pump from the lever ( Autoprofi). But there are few such reviews, and there is reason to believe that these buyers were simply out of luck. Unfortunately, even the best manufacturers can find defects. It is recommended to inquire about the warranty conditions when purchasing a jack.

The analysis shows that trolley jacks of the "household" segment are of sufficient quality, convenient and easy to use, relatively inexpensive.

Despite some drawbacks, they may well be recommended to all owners of cars with low ground clearance.

You can watch a video review of the Kraft 2t sliding hydraulic jack below.

The comment was sent successfully.