Expanded clay as insulation

Successful construction work requires the use of high quality materials that have all the necessary characteristics. One of these materials is expanded clay.

Peculiarities

Expanded clay is a porous lightweight material that is actively used in construction. For the production of expanded clay, clay or shale is used, which are fired in special rotary kilns for 45 minutes at a temperature of 1000-1300 degrees Celsius. The material is used not only in construction: it is often used in agriculture, home floriculture, horticulture, hydroponics, as an integral element of soil for terrariums.

Currently, the industry provides an opportunity to choose different types of expanded clay. The largest material is expanded clay gravel, the size of individual granules of which ranges from 20 to 40 millimeters. These are round or oval granules, usually brown-red in color. It is used as insulation in basements, on roofs, for garage floors, etc. This type of expanded clay has the greatest strength and the lowest thermal conductivity.

Crushed stone from expanded clay with parameters from 5 to 20 mm, which is often an additive for concrete compositions, will turn out to be somewhat finer. Due to the smaller granule size than gravel, crushed stone has a higher thermal conductivity. It consists of individual elements of an angular shape with sharp edges, which break during the technological process.

The smallest expanded clay product is screening or expanded clay sand. This material is produced through crushing and firing procedures. It is mainly used as a porous filler required in various construction mixes.

The main feature of the material is its excellent thermal insulation properties.... Naturalness and environmental friendliness are also indisputable advantages. Therefore, expanded clay is used as a natural economical insulation, filler for concrete mixtures (expanded clay concrete), heat-insulating and drainage material, backfill for interior partitions, etc.

Minus some modern building materials is their danger to human health. As for expanded clay, it can be used quite calmly, its naturalness is beyond doubt. Of the shortcomings, only a significant consumption of material can be called. To provide good thermal insulation, a fairly thick layer will be required, which is costly and not very practical for rooms with low ceilings.

Basic properties

Expanded clay Is a material that has many useful properties. Therefore, it is so often used in construction work. Let's highlight the following material properties:

- long term of effective operation;

- excellent thermal insulation;

- lack of smell;

- strength and ability to withstand significant loads;

- frost resistance (at least 25 cycles), which allows the use of expanded clay under various climatic conditions;

- environmentally friendly raw materials;

- fire resistance;

- affordable price in comparison with other types of insulation;

- the ability to absorb moisture (water absorption - 8-20%) and prevent its rapid evaporation.

Popular manufacturers

On the territory of Russia there is a research institute, which bears the name of ZAO NIIKeramzit. It is the scientific developments and technological equipment of this Samara institute that are used by all Russian plants for the production of expanded clay. Today, many factories are involved in this industry, located on the territory of 50 states.

Among the manufacturers there are both large enterprises and small factories. The final quality of the work performed depends on the choice of the manufacturer. If in the process material of unsatisfactory quality is used, then you should not count on a good result.

In addition, no one wants to overpay for products that do not meet the necessary requirements.

Among the large factories, it is worth paying attention to the following producers of expanded clay:

- plant "Keramzit" - the city of Ryazan;

- plant "KSK Rzhevsky" - Rzhev (Tver region);

- PSK - Shchurov;

- plant "Belkeramzit" - Builder (Belgorod region);

- Concrete goods-3 - Belgorod;

- brick factory "Klinstroydetal" - Klin;

- expanded clay plant - Serpukhov.

Of course, this is not a complete list. In each region there are enterprises producing expanded clay. In order not to be mistaken with the choice, you must first familiarize yourself with the offered products, evaluate the compliance of price and quality.

How to use it correctly?

The scope of use of expanded clay is very extensive. Given its properties and versatility, this does not seem surprising. The porosity of the material allows it to be used as a layer when pouring floors and arranging floors. It is successfully used in a wide variety of environments. For example, in the attic or on the balcony, in the basement and even in the steam room. Often it is used as a heater for the attic on concrete slabs or logs. Maintaining the required temperature is especially necessary for a bath. Therefore, an expanded clay layer in this case will be a good choice.

The technology of laying and backfilling expanded clay does not present any particular difficulty. You can do this work yourself. However, in order to avoid shortcomings in the technological process, it would be more correct to contact specialists.

For floor

The problem of floor insulation is very relevant for private houses, cottages, wooden buildings. Warming on the ground in a private house can also be carried out thanks to expanded clay. Floor screed can be done in two different ways. These are dry and wet methods. Beacons must be installed before starting work. When using a dry screed, the cleaned concrete surface must be covered with plastic wrap. At the same time, it should slightly cover the walls from below - by 5-10 cm. Then you need to fill in and level a layer of expanded clay. It should be borne in mind that the load on the base will be less if the granules are large.

The compacted expanded clay must be poured with a thin layer of cement milk. A couple of days after the material has completely dried, you can proceed to the next stage of work. In the case of using a wet floor screed, a mixture is poured onto a prepared concrete base and a covered film, which already contains expanded clay. Then they wait for several days to dry. The next step is the implementation of a thin main screed, on which tiles, laminate or other finishing material will subsequently be laid.

It is worth noting that this method is more convenient for use in private houses, where it is possible to position the mixer and all the necessary components for the solution.

Insulation can also be made along the lags. This method is very popular. In the room, wooden blocks are laid, which are pre-impregnated with an antiseptic. They are fastened using self-tapping screws strictly horizontally and in increments of 50 centimeters. In the resulting areas, it is required to fill in expanded clay to the upper edge of the bars. Additional processing with a concrete mixture is not required, since there is no load on the insulation layer.On such a structure, you can immediately lay plywood, chipboard, boards.

It is quite simple to calculate the amount of expanded clay that will be required to organize the floor screed. If the layer thickness is 1 cm, then 0.01 m3 per 1 sq. m. area. On some packages, expanded clay is calculated in liters. In this case, 10 liters of material are needed per 1 centimeter of the layer in the screed per 1 m2. The thickness of the layer in an ordinary apartment is 5-10 centimeters, and in the case of laying on the ground floor or above a room that is not heated, expanded clay is needed more —15-20 cm. Expanded clay is a high-quality support for any floor.

For walls

For the purpose of arranging the walls, it is most convenient to use a technology that provides for three layers... The first is made of expanded clay blocks. Medium is a mixture of cement milk and expanded clay (capsimet). Brick, wood or decorative panels can be used for the protective layer.

Another option for wall insulation is backfill, performed in the masonry cavity. Such an insulating backfill is carried out by three masonry: well, with three-row horizontal diaphragms and with embedded parts.

For ceiling

Insulation of the ceiling with expanded clay is used quite often. The work is done in several stages:

- first get rid of the previous layer of insulation;

- the base is cleaned from dirt and debris;

- a PVC film is mounted with an overlap of 10-15 cm, the joints are fixed with construction tape;

- the thermal insulation is backfilled: initially the material of the fine fraction is poured, then the coarse fraction is poured, for the last layer small granules are also used;

- the screed is being poured.

At negative temperatures, warmth in the room is retained due to the fact that warm air does not leave the room. In hot weather, on the contrary, expanded clay will not let the heated air inside.

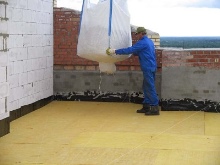

For roofing

Roof insulation is necessary to ensure the most comfortable living in the house. The insulation must be of a certain density and non-combustible. Expanded clay will be an excellent solution in this case. To insulate the roof, use the expanded clay fraction of 5-20 mm. Material of the M250-M350 brand is purchased in approximately the same proportions.

The thickness of the layer will depend on the type of the particular roof. For a pitched structure, heavy loads are contraindicated, since a margin of safety for snow must be maintained. Therefore, the optimal thickness will be 20-30 centimeters, while for a flat roof, the thickness should be slightly larger and be 30-40 centimeters. This will provide good isolation, but financially can be cumbersome.

Insulation of a pitched roof begins with packing closely, without gaps, flooring from edged boards or OSB sheets, which is placed on top of the rafters. A vapor barrier film is laid on it, and the seams are glued with adhesive tape. Next, there is a horizontal fastening of the bar with a step of about 50 centimeters. Expanded clay is poured between the beams and compacted. The material is covered with a windproof membrane. After filling the counter-lattice, the roof is covered.

To insulate a flat roof, you will initially need to prime it and apply bituminous mastic. After that, a layer of waterproofing is laid and sand is poured in a layer of 3-5 centimeters, everything is compacted. Further, expanded clay is backfilled, the layer of which is 7-12 cm, and then, alternating layers, they reach the required thickness.

The final stage of work can be different depending on the specific circumstances.

For information on how to insulate the attic and walls with expanded clay, see the next video.

The comment was sent successfully.