How to make construction goats with your own hands?

Construction goats - a design that allows one or more workers to carry out work at a height that exceeds the height of a person. They are equipped with a fixed horizontal platform, they can be supplemented with protective fences and other aids. The goats are both stationary and mobile.

The frame of the auxiliary structure is assembled from wood or metal. On the construction market there are models of ready-made goat of a modular type. They are a collapsible transformer structure. The latter is equipped with rotating wheels, brake clamps and fasteners.

This type of scaffolding is a temporary device. After completing the necessary work, they are dismantled. The material from which the body was made, if there is sufficient integrity, can be used for other technical purposes.

To carry out construction and finishing work, you can make homemade goats.

Advantages

DIY Scaffolding vs. Shop Equivalents have a number of advantages:

- low cost;

- adaptation functions for a specific building object;

- the presence of variations of random modification to fit your needs;

- the possibility of further misuse.

To make your own goat, you can use the material at hand - boards, a profile pipe, plastic and others. This fact significantly reduces the cost of the assembly object.

Homemade scaffolding can be remodeled and modernized to best fit into a building's environment. This is especially true when working in tight spaces. They can be adjusted in height, width and length. Retrofit with steps, handrails and even a block for lifting material.

Preparation

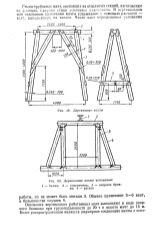

Assembling a suitable trestle begins with the design phase. It is necessary to draw up a detailed drawing, which will contain indications of general dimensions and individual parts.

The formation of drawing diagrams is influenced by what kind of forests will be. They can be two-piece - folding or one-piece. In the first case, two gantry supports are assembled, on which the boards are placed. This allows you to adjust the length of the scaffolding, depending on the need. Their width is determined by the width of the supporting elements. In the second case, a one-piece structure is made with fixed parameters of height, length and width.

The simplest options for homemade scaffolding are those made from wood materials. For assembly, you will need a set of basic tools and consumables:

- hammer;

- hacksaw (jigsaw);

- screwdriver;

- measuring instruments (tape measure, ruler).

- self-tapping screws;

- drill;

- fastening metal products.

Manufacturing

Let's consider step by step how to make goats yourself.

Two-element

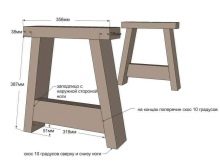

It is necessary to prepare construction details. Workpieces are cut from a bar or board with suitable dimensional parameters - legs, upper crossbars, reinforcing jumpers.

The length of the workpiece, which will serve as the upper crossbar, is determined by how wide the goat is needed in a given situation. Its optimal size is 35-50 cm.

The height of the bars used as legs is determined by the needs of the person in each case. This value can vary from 0.5 to 1 m.Exceeding the height of one meter is not recommended due to the decrease in the stability factor of the final structure.

As shown in the drawing, the end edges of the legs should be cut at an angle that allows them to spread apart. This angle is verified as follows:

- put the blanks for the legs on a flat floor so that their location resembles the sides of the trapezoid;

- lay the upper crossbar on the narrow part of the trapezoid, creating its improvised top;

- on the future legs, make marks along the crossbar, like along a ruler;

- cut the workpiece according to the verified marks.

After these manipulations, the upper bar and legs will connect at the desired angle. They are fastened using self-tapping screws with sufficient length, which are screwed into the upper side of the future goats. In order to avoid cracking of wood, planting holes are drilled for each self-tapping screw. The diameter of the holes must not exceed the thread diameter of the screws.

The end edges of the reinforcing web are cut at an angle. The latter is determined by the same method that is used when carrying out an angular cut on legs. The blank for the lintel is placed on the legs already attached to the top bar. Marks are made on the inside of the legs on the lintel, along which facing is performed.

Important: the connecting bar is located at a distance of 10-15 cm from the lower edge of the legs. The jumper is attached using self-tapping screws.

The product's resistance to deformation loads is increased by the use of metal fasteners. Metal corners are screwed into the inner corners using shorter self-tapping screws. If the side of the connecting jumper is flush with the legs, you can strengthen their abutment using metal perforated plates screwed on with self-tapping screws. The corners and plates are fixed with at least 4 self-tapping screws - 2 for each individual part.

The second pair of "legs" is made according to the same principle. In cases where the platform deflection is created due to the excessive length of the goat, it is necessary to assemble a third pair of "legs", which is installed in the middle.

The stability of the trestle obtained is ensured by adjusting its "soles" to the floor surface. "Soles" should have an optimal angle that allows them to adhere to the floor covering the entire plane. This factor ensures the functional safety of work at height. Planks of sufficient thickness are used to create a working platform. They are placed on the trestles in such a way that their edges protrude 15-20 cm beyond the “legs”, without creating excessive deflection in the middle. Boards can be attached to the legs with self-tapping screws - 2 pieces for each point of contact.

A distinctive feature of this type of construction trestle is the possibility of their folding storage. It is enough to dismantle the flooring from the boards, and the "legs" can be compactly placed in the place where they will be stored. And also two-piece trestles can be used as a folding joiner's workbench-table.

Whole

One-piece trestles are made according to the two-piece principle. In this case, the "legs" of the goat are interconnected by boards representing the working platform and special jumpers.

The jumpers serve as structural reinforcements and prevent the goats from loosening in the transverse and longitudinal planes. It is very important to correctly mount this reinforcement so that it fulfills its purpose in the best possible way.

The connecting bars are located diagonally on all sides of the solid trestle. The first attachment point for the lintel should be located as close as possible to the angle that forms between the platform and the pair of feet. The second connection point should be located at the shortest distance from the "sole" of the "leg".

Important: the diagonal is fixed exactly in the “leg”.

If on this side of the goat the diagonal bridge was screwed at an angle from left to right, then on the opposite side the direction of the angle will be from right to left.

Both pairs of goat legs and the platform should form a slightly angled angle. This will ensure the reduction of the longitudinal swinging of the structure during operation. One of the pairs of legs, from the side of which the trestle will be lifted, can be positioned at a more obtuse angle. To facilitate lifting, it is worth equipping it with horizontal rungs - steps.

Construction goats are very often needed to solve everyday problems. The instructions in the video below will allow many men to make them with their own hands.

The comment was sent successfully.