Features of houses from gas silicate blocks

Knowing the features of houses made of gas silicate blocks is useful for any individual and not only a developer; we are talking about a number of subtleties of house projects and their construction. It is necessary to carefully study the possible options for one-story and two-story buildings up to 100 sq. m and more. In addition, you will have to pay attention to the interior decoration, and in order to know even better what you have to deal with - read the reviews of the owners.

Advantages and disadvantages

It should be emphasized right away that the statement about decent thermal insulation in houses made of gas silicate blocks is quite justified. It is indeed comparable to the characteristics of high-quality wooden buildings, even without taking into account additional insulation. Also in favor of such structures is the simplicity of the work and the relatively high speed of installation. It is quite possible, if you try, to start work in the first half of summer and move into a fully equipped dwelling before the leaves fall. At the same time, the exchange of air with the external environment is very stable and efficient, regardless of the season - which makes it possible to provide an excellent microclimate.

But still, rather favorable conditions are achieved only with the use of good waterproofing. Inattention to her or the desire to save money often gives rise to complaints about a too cold house.

The common opinion about the simplicity of construction is also true - however, everything here depends on the geometry of the blocks. It is relatively easy to lay out a wall of standard-shaped modules. But if you achieve some delights, you will have to spend much more time and overcome a number of problems.

The desire of manufacturers to improve the heat-saving qualities of their product in every possible way is understandable. However, because of this, the bearing capacity often suffers, and therefore it is important to carefully select the specific material. Other relevant block properties include:

- ease;

- excellent sound insulation (noticeably better compared to brick and concrete);

- complete absence of substances toxic to humans and animals;

- optimal vapor permeability;

- low frost resistance;

- insufficient suitability for screwing in and driving in fasteners;

- incompatibility with cement-sand plaster;

- the obligatory application of conventional plasters in two layers.

Projects overview

For reasons of economy, quite a few people choose one-story houses with an area of up to 100 sq. m. Such buildings are suitable for small families, and even for single people seeking space and comfort. They are also often used in summer cottages. And the very possibility of accommodation in a limited area is also quite pleasant. The typical layout of such a dwelling implies the allocation of:

- kitchen (optionally combined with a dining or guest area);

- living room (sometimes combined with a dining room);

- bathroom;

- a single bedroom (or twin bedrooms of approximately the same area);

- utility room (where infrastructure facilities, important household items and minor unnecessary things are located).

The mentioned combination of adjacent rooms is not accidental. This is the only way to ensure the optimal functionality of buildings and at the same time not to inflate their footage additionally. Columns, low partitions, bar counters and other furniture are often used for visual delimitation.

The use of built-in wardrobes is also an important point. They allow you to place many stored items without taking up additional space.

And yet, as if in a house of 6 by 8, say, meters, you did not have to "squeeze" - you still need to separate the sleeping and guest areas. This requirement is associated with elementary psychological and sanitary and hygienic nuances. In any case, there must be a main wall between them. When laying buildings elongated in length, they try to clearly distinguish the left and right wings. Then the guests are received and during the day they gather in one part, and for the evening and night hours they move to the other wing.

In modern standard buildings, more and more attention is paid to one-story houses with a garage - and the arrangement of gas silicate dwellings of this kind is not too different from the construction of frame buildings. Extension of a parking space to the house allows you to:

- do not rack your brains where to set aside a site for him on the site;

- use common heating, electrical communications;

- to simplify the equipping of the garage with water supply and sewerage;

- get from one zone to another faster;

- faster to leave and arrive.

The entrance to the garage boxes is recommended to be located on the same side as the exit. A vestibule must be equipped to isolate the room from exhaust gases. It is useful to move the garage closer to the kitchen or utility room (pantry) to reduce the burden of carrying heavy loads. At the same time, one must pay attention to fire safety standards - after all, the garage is a source of increased danger. Therefore, the wall between it and the living space is finished only with fireproof materials or materials with a high degree of fire resistance.

In some cases, it is appropriate to build not a one-story, but a two-story house from gas silicate blocks.

For your information: it is not worth building even taller buildings from this material due to the fact that it is unsafe. No wonder such a limitation is established in the usual building codes and regulations.

Two floors are more spacious and more comfortable in everyday life. Important properties:

- occupying a smaller area with the same area inside;

- the best view from the second floor;

- simplification of zoning;

- poor sound insulation;

- cutting down the usable area by stairs;

- difficulties with the descent and ascent, especially for children, the elderly and the sick;

- difficulties with redevelopment.

With enough money, you can equip a one-story house with an area of 150 sq. m, even with a terrace and an attic. It is easy to equip 2 or even 3 bedrooms. You do not need to save on the volume of the kitchen and dining area.

Only professional architects will be able to competently prepare the project. Without the need to redo typical projects at your own discretion, you should not.

Material selection

It is already clear that a variety of types of houses are built from gas silicate, differing in area, layout and number of storeys. However, it is important to know which material is best to choose for a particular solution. To begin with, they clearly distinguish between wall and partition structures. It is possible to use a wall block for arranging partitions, but it is expensive and difficult; Reverse replacement is not allowed at all.

An important property is the density of the structure - the higher it is, the stronger the structure will be; however, at the same time, the thermal qualities of the products deteriorate.

Additionally take into account:

- the presence of grooves and ridges;

- linear dimensions;

- manufacturer's brand.

Payment

There are a large number of sites offering to calculate the need for gas silicate or aerated concrete blocks. But not everything is as simple as it seems. Sometimes you have to cut off excess material. And you need to strive to ensure that the amount of these scraps is minimized. However, even the most diligent builders usually lay down an expense for illiquid assets of 3-5%; beginners need to make a tolerance of 6-8%, and also do not forget about calculating the mass of products.

You must be aware that the calculations in online calculators are always approximate. More accurate figures can only be given by experienced builders. The correct final figure is always obtained after subtracting the area of the opening.

It is worth considering that the cellular material absorbs moisture by definition. Therefore, its volume and severity can vary within fairly wide limits, the conclusion is that you will have to immediately lay a stock.

Construction stages

Foundation

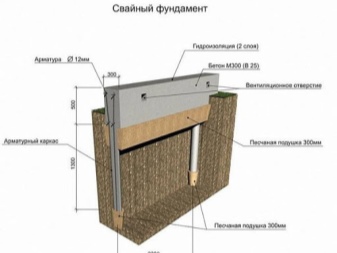

Since gas silicate blocks are relatively light, it is easiest to build a house on their basis using a pile foundation. The accuracy of the installation of all elements is verified according to the building level. Since special channels for communications are almost always needed, it is very difficult to do without wall chasers. In advance, you need to knock down and take out all the trees (shrubs), level the site as much as possible.

The choice of the type of foundation and the specific scheme for its implementation are determined by:

- the region where the person lives;

- the actual state of the soil;

- the relief of the site;

- the size of the load;

- the material capabilities of the owner.

Insulation of foundations is mostly carried out outside. If not carried out at all, frosty swelling of the soil can even destroy the house. The usual options are to use expanded polystyrene or expanded clay.

If it is decided to equip a slab base, it must be thermally insulated at the construction stage. It is clearly too late to do this during operation.

Waterproofing

When building with your own hands, this moment should also be given primary attention. Special protection is needed both outside and inside the foundation (plinth). In addition to the use of various materials, the use of a water-diverting drain will be required. A traditional and time-tested solution is roll waterproofing. However, you can resort to mastics, and to powders, and to the use of special films - in the end, it's all a matter of taste.

Main row

The basic technology of work does not differ fundamentally from the manipulation of other block materials. The base must be prepared for work, it is leveled as much as the site allows. About 30 mm of cement mortar is laid on top of the waterproofing. Then a reinforcing mesh is used. The first tier of blocks is always laid out of the corner - this way it is easier to exclude the appearance of errors.

Subsequent rows

They are taken up only after full grasp of the first level. Usually you have to wait 2 hours (only specialists can say more precisely).

Experts advise using a special glue for aerated concrete. The thickness of the adhesive layer is a few millimeters. Chasing an excess of connecting compound is impractical.

Reinforcement of walls

This procedure is usually carried out with every fourth row of blocks. But if the load is large enough, then you need to strengthen the wall every three rows. Often limited to laying steel mesh on mortar. When using reinforcing rods, however, a much better result is achieved.

The grooves for the rods must be knocked out with a wall chaser and partially filled with glue. The reinforcement itself at the places where the lines are interrupted is overlapped.

Jumpers

Clearly constructing lintels is no less significant than gradually overlaying the structure with decorative materials. Most often, consumers choose already initially reinforced structures. A common mistake is “by eye” editing; experienced builders always measure and calculate everything in advance. Load-bearing lintels are made as strong as possible, but non-load-bearing lintels are enough to make and place so that they themselves do not fall off under the applied load. The loads themselves are calculated:

- by the method of an isosceles triangle;

- by the square principle;

- according to the "1/3" method.

Overlapping

In any case, in a private house, it is worth insulating the floor - this will guarantee optimal comfort.It must be remembered that the thermal insulation of gas silicate is carried out only after additional drying, and not immediately after being removed from the factory packaging. For insulation, they use polyurethane foam, mineral wool, expanded clay and some other materials.

The floors themselves are usually performed according to a monolithic scheme. However, sometimes, when the load is critical, a precast-monolithic solution is chosen.

Internal and external finishing

Quite a lot of people are trying, despite all the problems, to plaster the outside of the facades of gas silicate. It needs a mixture that is vapor-permeable and resistant to temperature extremes. A primer is preliminarily applied, which increases the readiness of the surface for processing.

Fiberglass reinforcing mesh proved to be at least as good as steel counterparts. The mesh must be pulled tightly, avoiding sagging.

The finishing decorative treatment is carried out at least 48 hours after the application of the plaster.

Often they try to decorate the facade with bricks from the outside. But for this, initially, the foundation must be wide enough to support them as well. Moreover, an additional air gap is required to exclude the formation of condensation. If the installation of bricks is going close to the blocks, then it is necessary to make a non-rigid bond between them. Otherwise, mechanical deformation is likely due to the difference in expansion coefficients.

For aesthetic qualities, siding is considered the best option. It is best to sheath this material with vinyl-based siding. But you can also use metal structures (based on the same crate). A wooden frame is preferred for vinyl.

But indoors they use:

- lining;

- drywall;

- plastic panels of various types.

Review overview

In conclusion, it is worth giving a brief summary of the opinions of the owners of gas silicate dwellings. The reviews say:

- strength and stability of structures;

- the absence of usually protruding seams;

- hygroscopicity of the material itself;

- energy efficiency;

- the likelihood of heavy precipitation without strengthening the walls from the outside;

- attractive appearance even with minimal finishing;

- lack of any discomfort (subject to building codes).

About laying a house from a gas block, see the next video.

The comment was sent successfully.