All about fire protection of air ducts

When installing a ventilation system, it is very important to take care of its fire protection. It is necessary to carry out fire protection of air ducts, following fire safety rules, as well as using high-quality materials.

Description and purpose

Ventilation pipes are usually made of very lightweight materials. This is done in order not to overload the main supporting structures of the future building. But in the event of a fire, the thin walls of the pipes burn out very quickly. As a result, smoke quickly fills all rooms in the house. Besides, when the air ducts become hot, nearby objects can be ignited by their heat. This leads to further spread of fire. If the floor is damaged in the process, the supporting structure itself may be damaged.

The implementation of fire protection makes it possible to protect light pipes from severe overheating and melting. Insulating air ducts also helps to slow down the spread of smoke and fire in the room. In addition, some varieties of lightweight materials expand in volume when heated. Thanks to this, oxygen does not enter the room where the fire is raging, which means that the fire gradually dies out.

Methods and materials

For fire protection of modern ventilation, different means with different characteristics can be used.

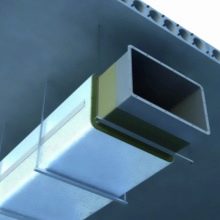

Basalt mats, slabs, sheets

Basalt is a substance of volcanic origin. It contains iron and silicon impurities. When exposed to hot air, this material does not emit any toxic substances, and also does not change its shape. For this reason, basalt is often used as fire protection. Basalt fiber without any impurities is used for pipe insulation. This isolation method is popular. This is due to the fact that the structural protection of the ventilation system is inexpensive. In addition, mats and sheets can be easily assembled by yourself. They are suitable for protecting air ducts on the roof, in the house and outside.

It should be remembered that the materials used increase both the dimensions of the pipes and their weight. Therefore, such a heat-retardant coating cannot be used in all cases.

Fire retardant paint

Often, special varnishes and paints are used for fire protection of the ventilation system. They swell when exposed to hot air. This layer has high thermal insulation properties. A big plus of such coatings is that they are applied very quickly and easily. Even hard-to-reach places can be treated with fire retardant paint. Therefore, these materials are often bought for insulating pipes that are in a corner or are too close to the wall. Coating a metal substrate does not take long. But this method of thermal insulation has its drawbacks. Such funds are less effective. In addition, they are expensive. Therefore, it is completely unprofitable to use them for processing a large ventilation system.

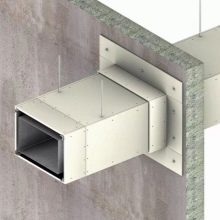

Barrier

This method of protecting the ventilation system is less popular. Its essence is to create a solid barrier around the ventilation system. This can be a brick box, a stucco mesh, or a layer of concrete. Such materials make the structure much heavier. In addition, the use of bricks and concrete requires prior reinforcement of the anchorages. Therefore, now fire protection barriers are used only in private homes.

Refractory mastic

This method of fire protection is quite effective. A thick layer of mastic or paste is applied to the surface of the duct. These products are usually based on silicates, nepheline, mineral or asbestos fibers. Therefore, the ventilation system is reliably protected from heating. Most fire retardants are inexpensive. Processing pipes with such products does not take much time. At the same time, you will not be able to use the paste yourself. The fact is that for the application of mastic it is necessary to have specialized equipment, and it is also worth noting that all kinds of refractory pastes are unstable to humidity and temperature extremes. If the product is used in unsuitable conditions, the protective layer will crack very quickly. In addition, since the paste is applied to the surface in a thick layer, it significantly increases the weight of the structure.

The best brands of compounds

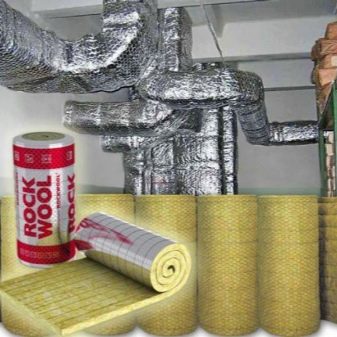

When choosing materials for insulating systems, you need to pay attention to the products of the most popular manufacturers. The following companies are engaged in the production of modern basalt mats.

- Rockwool. The products of this brand are produced in rolls. Thermal insulation materials are lightweight. Moreover, they are quite durable. They can be used to insulate the air duct both from the inside and outside the house.

- Pro-Vent. This material is also sold in rolls. There are several options for such mats. There are coatings with foil, metal mesh and silicon fabric.

- "Buffalo". Insulation material is sold in large rolls. It can also be clad with silicon, basalt, or strong aluminum foil. Products from this brand are non-toxic and durable. It not only provides a high level of thermal protection, but also helps to suppress noise and vibration.

High-quality paint is produced by such brands as "Thermobarrier", "KROZ" and "Kedr-Met-V". Products from these manufacturers are easy to apply to the surface and are highly durable.

Coverage Tips

You need to buy fire retardant materials in proven places. The quality of the products must comply with the standards. Therefore, it is best to purchase coatings in large hardware stores. In this case, the probability of buying a fake will be minimal. When choosing a coating, you should pay attention to the following points.

-

Fire resistance class. This is the main parameter. It indicates the time during which the selected material can withstand exposure to hot air. For finishing the ventilation system, it is worth using funds of a class not lower than "B". They are semi-fire resistant. For the insulation of the smoke exhaust system, it is worth using more fire-resistant materials.

- Features of the room. When choosing insulating materials, it is necessary to consider in which room the ventilation system is located. If it is possible to further strengthen the fasteners, you can choose heavier materials. If it is not there, you should give preference to light paints or basalt mats.

- Features of installation. If it is necessary to install fire protection in a short time, a person should choose materials that are easy to assemble or dry quickly. It is also important to consider whether finishing takes place at the stage of building a building or in an already built room. In the first case, you can use all available materials, because a person has access to all ventilation ducts. The finished building has many hidden and hard-to-reach areas. Not all materials are suitable for their isolation.

- Additional characteristics. If a person plans to insulate a ventilation system that is located in an unheated room or outside the house, the material requirements will be slightly different. They must be resistant to temperature extremes, sudden gusts of wind and humidity. In this case, the transit air ducts will be well protected. When insulating interior rooms, it is necessary to choose fire protection means that provide a high level of sound insulation. This is especially important in living rooms.

- Decorativeness. The appearance of the finish also plays an important role in choosing the right material. If the ventilation system is in sight, and the person does not plan its additional finishing, it is worth choosing fire protection that will harmoniously fit into the interior of the house or apartment.

The right material will do its job well

Design and installation

It is quite possible to do the insulation of the ventilation system in a house or apartment on your own. Without assistance, a person can use paint, varnish or basalt mats. The latter are most often used in work. The isolation process consists of the following steps.

- First you need to complete a project for future work. It is required to think in advance about the method of fastening the basalt mats, and calculate the number of parts that will be used.

- Further, the surface of the air ducts must be thoroughly washed and degreased. Usually acetone is used for this purpose. You need to work quickly. In this case, the windows must be open.

- Next, you need to cut the mats. In this case, it is very important to retreat 100 mm from the edge of each of them. In this case, it will be easier to fix the material on the duct.

- After that, you need to prepare the glue. The product is gently applied to all protruding parts of the duct. It can be applied in one or two coats.

- Further, pieces of mat are glued to its surface. They must be overlapped.

- When the work with the protruding parts is finished, you can start working with the flat part of the duct.

- If necessary, the joints should be additionally glued with aluminum foil. Self-adhesive foil can also be used instead. Top mounted mats can also be secured with wire, clamps or metal brackets.

When working with basalt wool mats, it is imperative to protect the skin and respiratory tract. After all, the small particles that they contain are dangerous to human health. Therefore, it is important to prevent them from entering the body. If done correctly, the house and all its occupants will be reliably protected in the event of a fire.

For information on how to properly protect the air duct from fire, see the next video.

The comment was sent successfully.