Features of round ducts

Ventilation pipes are an important element of communication systems, the main task of which is to direct air masses. The design of the air duct is offered in different versions, for your attention a more detailed acquaintance with the equipment, its features and advantages is presented.

general description

A round duct consists of pipes with fittings. For their manufacture, galvanized or stainless steel is used. This device is used for ventilation systems located both in residential and industrial premises. The circular section is manufactured in different sizes, if necessary, you can make an individual order.

The main advantages of the product include the following. Such air ducts have excellent aerodynamic characteristics, due to which it is possible to use less powerful and expensive equipment in the room, which often consumes a lot of electricity. The design is remarkable for its reliability and durability, so it will last for a long time. Round ducts have a high rigidity compared to other shapes, which makes installation easier. The device is offered at an affordable price, so it has already earned great popularity. Much less materials are required for such a product, so they can be considered economical, the same applies to the consumption of insulating elements.

In an air duct of this cross-section, the flow moves much easier, so the noise level is minimized, which means that you do not have to spend money on serious sound insulation.

Views

The production of air ducts has gained wide popularity, today on the market you can find a wide variety of such equipment, each type has its own characteristics and advantages, which are important to familiarize yourself with before buying.

By type of manufacture

Round ventilation ducts can be longitudinal, spiral-welded and spiral-wound. Products are also divided into rigid, semi-rigid and corrugated hoses. The latter can be with or without a frame. The main advantage of a flexible duct is that it can replace a fitting connection that changes direction. By density, products are marked "P" (dense) and "N" (normal).

The connection method also divides the models into flanged and flangeless. The first method consists in joining the elements with bolts and seals, the latter are fastened with a bandage. Straight seam air ducts have a rigid structure due to seams. Welding ensures high tightness and strength. Often, the fastening is done in this way, since the equipment is more concentrated for operation on static ducts. During production, bending machines and extruders are used. Rigid lines are easy to mount and have excellent aerodynamic performance.

The only drawback is the weight of the structure, which has many adapters and turns, due to which additional fastening is always needed. For the wall, wire steel reinforcement is used, the boxes do not require elements, since they are elastic, so they are easy to bend. The grooved surface on the inside reduces the air flow rate, while the noise level increases.

As for the semi-rigid ventilation ducts, they can be made of both steel and aluminum. The products have spiral seams on the sides, the boxes are strong, no turning and connecting elements are required for installation.

By tightness

This is an important criterion when choosing a device for a ventilation system. Such an indicator is indicated in the documentation, it speaks of air loss and is determined by the degree of pressure. Thus, circular air ducts are divided into class A (1.35 l / s / m), class B (0.45 l / s / m), and class C (0.15 l / s / m).

Materials (edit)

The pipes are offered in plastic and metal versions. On the market you can find products from galvanized, stainless and black steel, as well as aluminum products. Such air ducts are distinguished by a long service life, fire resistance and durability. At the same time, black rolled products are not highly resistant to corrosion. The main advantages of aluminum models include elasticity, which guarantees flexibility, the bonus is incombustibility and anti-corrosion.

As for plastic devices, they are several times cheaper, but they are much more exposed to mechanical damage, therefore they are not able to serve for a long time. Some models cannot withstand hot air at all, which is important to consider when buying.

The advantage of plastic is its smooth surface, which provides sound insulation and high flow rate.

Reinforced-plastic walls consist of three layers, such a structure is strong enough, does not require another thermal insulation, but this is an expensive equipment. Plastic does not react to high humidity, and is also resistant to acidic or alkaline environments. Such products are often installed in food and pharmaceutical industries. The smoothness of the inner walls ensures the flow rate and minimizes the pressure loss.

Dimensions (edit)

This parameter is determined by the diameter of the pipeline. On the market you can find standard products that are thick enough to fit any ventilation system. If we talk about GOST, it should be noted that the length of the metal ducts is 125 mm. The size depends on the assortment used in production. Shaped and straight products are regulated by different documents, including GOST. The diameter can start from 100 mm and 120 mm, reaching 150 and 200 mm, the diameter of some is 300 mm. Products intended for use in ordinary environments are made of galvanized steel with a thickness of 0.5-1 mm, from black steel 1-4 mm.

Top manufacturers

Before deciding on a choice, you need to familiarize yourself with the rating of the best factories that offer quality products. This list includes LLC "Vertex"which has been designing and servicing ventilation systems for over 20 years, which speaks of high standards and an excellent reputation.

American manufacturer ATCO is engaged in the manufacture of high-quality insulated and non-insulated air ducts of various types. The company located in Vladivostok, "KONUS" manufactures fittings and materials for ventilation systems using German equipment.

The next in the list of the best manufacturers was Uniflex, which offers flexible corrugated products made of polymeric materials, in the assortment you can find flexible air ducts reinforced with steel wire. This can also include "Best Vent", "Sigma-Stroy" other.

Additional elements

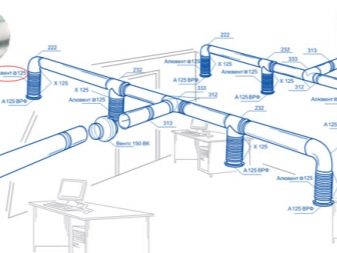

Different accessories are required to install the air duct. For example, a silencer is an integral part of the ventilation system, this is required for sound insulation. And also experts use a round tee, with the help of which various air ducts can be connected to each other, thanks to this, a complex system can be created.

For products with a circular cross-section, a fitting is required.

It should be noted such an element as a carbon filter, the task of which is to purify the air in the room, it removes odors, and also retains dust and other impurities. To ventilate any room, an air flow is required, which is created artificially using a duct fan. And for overlap, a check valve is installed, so the movement will be in the right direction. Thus, the connector, filter, tee and other elements are an important part of the entire ventilation system.

Application area

No room can do without air ducts, be it a residential building, shopping and entertainment complex, office, restaurant or other commercial enterprise. This equipment is especially required in the industry. It is safe to say that this is an integral unit for ventilation, which is everywhere.

Selection Tips

To find the right model, you need to follow certain criteria, study the technical characteristics and compare the benefits. The first step is to decide where the ventilation system will be installed and what the conditions will be. And also the area of the room, the temperature regime and even the chemical composition are taken into account. The power of the ventilation equipment plays an important role. As for the choice of an air duct - made of plastic or metal, it all depends on the aggressiveness of the environment where it will be used. The product with galvanized walls is suitable for temperate climates where the temperature does not exceed 80 degrees Celsius. For high humidity, this is the best option. This also includes stainless steel, which can withstand up to 500 degrees, it is heat-resistant, so it is often used in industrial enterprises.

Mounting

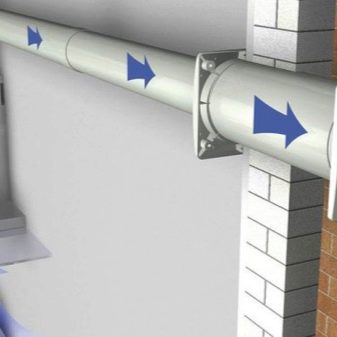

You can make the installation yourself without outside help if you follow the recommendations. The assembly must begin with large sections that will be joined to each other using fittings such as corners, tees and adapters. Corrugated hoses with medium stiffness and flexible are mounted after stretching. To prevent the sleeve from sagging, it is necessary to use suspensions and clamps, fixing it every one and a half meters. If possible, it is better to avoid a large number of bends and turns, the corners should be twice as large in diameter. Each seam is treated with a sealant.

If you need to mount to a ceiling or wall, you must immediately purchase the fixing accessories.

The comment was sent successfully.