What are corrugated ducts and how to install them?

When installing a standard ventilation system, it is difficult to do this without an air duct. They supply or remove air from a certain area of the room. And for this purpose, corrugated air ducts, ventilation and air conditioning buildings, spaces of different functionality are actively used.

Advantages and disadvantages

Corrugated air ducts are otherwise called flexible, and this adjective is their main characteristic. The flexible air duct consists of a spiral wire frame. And it is spun in either polyvinyl chloride or aluminum polyester. Other materials can also be used, as long as they are sufficiently elastic. There are flexible products without a frame in the implementation today, and their functionality is the same.

What are the main advantages of corrugated air ducts:

- they are simple and easy to install;

- dismantling them is also easy;

- repairs will not be a problem, even if you have to carry out it more than once;

- service work is also convenient and will not cause problems;

- it is easy to store and move the pipe;

- lay the air duct quickly;

- light weight;

- the ability to easily change the configuration of the structure according to the request;

- high rates of fire resistance;

- affordability of the price.

The result of ventilation is almost always associated with the occurrence of vibration, but the flexible design instantly dampens it. And it is also worth noting the margin of safety of modern pipes, the service life. They are resistant to rust and are not afraid of chemically aggressive substances. The diameter of the corrugated air ducts coincides with rigid pipes, and therefore there is no problem to mount them in one system.

What are the disadvantages of such designs:

- if you design the air duct incorrectly, and then install it with errors, the noise level may increase;

- a flexible air duct is a multilayer system, but the thickness of the layers is insignificant, therefore, with not the most delicate installation, they can be damaged.

In any case, flexible systems have much fewer negative qualities than positive ones. And finding an alternative that would not have any disadvantages at all will definitely not work. Moreover, taking into account the fact that each plus can be accompanied by even small positive moments. The low weight of the models reduces the cost of fasteners, which saves the overall cost. Moreover, the flexible system can even be placed on decorative structures.

But the main thing is that the corrugated pipe creates the desired bending angle of the duct. There are certain limitations, but within a given limit, you can still position the pipe so that it is convenient and economical for space.

And also it can be used even in the context of low temperatures, and extremely low too.

Views

Most of these systems are cylindrical. But you can also find rectangular products, it's just that the demand for them is not so high.

What other corrugated ducts are there?

- Steel. For their manufacture, either stainless steel or galvanized steel is used. They are less pliable due to the nature of the material. But these are definitely durable products with a high margin of safety. They are not afraid of high temperatures and combustion.

- Aluminum. They are made from strip, to put it simply, special aluminum foil. The thickness of such material will not be higher than 0.12 mm. Manufacturing takes place using a rolling machine, which helps to push the stiffeners. Meanwhile, it is this process that is called shirring.At the edges of the product, the equipment also helps to make special locks.

- Plastic. Semi-rigid PVC products are mainly used to remove dust and gas from objects. In the chemical industry, such products will be especially in demand. But they do not demonstrate high resistance to extreme temperatures, this must be taken into account when choosing the type of pipe. The maximum that the PVC air duct can withstand is 65 degrees. At the same time, they perfectly withstand a humid environment, bend well and do not burn, and are also resistant to chemical attack. The active introduction of silicone systems is also being considered.

- Fabric. To make such systems, synthetics are used, most often polyester. Such channels are so good that they exclude the observation of condensate on the surface. And such systems also do not have to be additionally insulated.

The material from which the channel is made significantly reduces the noise level during operation. And you can clean the system simply by giving it to the wash.

And also air ducts can be with or without insulation. Insulated are made using heat-insulating material, which is used to cover the channel in production. And this system helps to avoid condensation on the surface of pipelines. And the latter often occurs if the system is localized in a room where temperature jumps occur. Condensation can also occur if the temperature difference between the supply air and the atmosphere at the facility is relevant. The heat insulator is usually represented by glass wool, mineral wool or polymer materials.

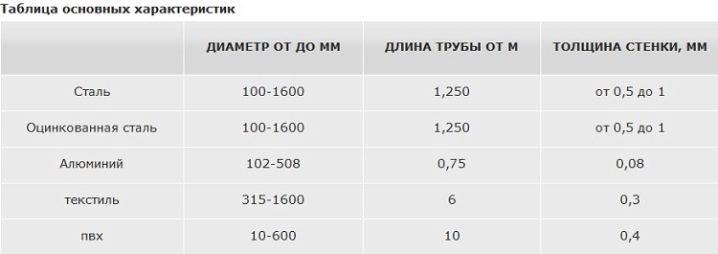

Pipe diameter is another reason for the classification of corrugated ducts. For example, steel systems range from 100 mm in diameter to 1600 mm, just like galvanized ones. Aluminum - from 102 mm to 508 mm. Textile - from 315 mm to 1600 mm, and PVC - from 10 to 600 m. The running dimensions are considered to be diameters of 60 mm, 120-125 mm, 150 mm, 160 mm, 200 mm.

Mounting

Let's say you have to mount a ventilation corrugation for a regular household hood. And all the work can be divided into two stages - preparation and implementation itself. In the process of preparation, you have to choose the brand and size of the pipe, decide on them, and buy the structure itself. Then find all the tools you need for installation.

What can be useful for installation:

- electric drill or screwdriver;

- pencil and tape measure;

- scissors or a hacksaw for metal;

- screwdriver.

Installation algorithm.

- Make precise markings on the plane for installing the duct. At the same time, the marking for the installation of the hood, since the system will be a single one.

- Drill the wall at the point where the ventilation duct will exit into the kitchen to position the adapter / grill there.

- Install the adapter in the place prepared for it. This is necessary for fixing the air duct.

- Fasten with a clamp to the corrugation adapter.

- Put the other end of the air duct on the outlet of the hood, fasten it with a clamp.

- Fasten the joints of the corrugation with metal tape.

- If the length of the purchased air duct is longer than what is needed in a particular case, then even before attaching the hood to it, the length must be adjusted. This can be easily done with scissors or a hacksaw for metal.

That is, in a normal everyday situation, there should not be any special difficulties in installing the corrugation. But still, situations are different. For example, the section of the air duct is long, and several elements of the corrugated structure must be connected to each other. For this, special inserts will be used, which are installed directly inside the channel, immediately into two abutting parts. Then the joints are pulled together with clamps. If you can't find the inserts, you can use construction tape for the same purposes. And this tape must be made of the same material as the duct.

The question often arises, how to hide the corrugation in the kitchen. It's probably easier to do this with the kitchen cabinet doors, although the space behind them will not be as functional as it could be.Plasterboard structures also help out, like all kinds of decorative boxes.

And you can also do a little trickier and lay a corrugation in the kitchen right behind the false ceiling.

Such a standard channel will last for 10 years, after which fat will inevitably accumulate inside it, which cannot be fully removed. And also it is worth remembering that it is impossible to wipe the outer surface of the channel with detergents - third-party odors may appear at least. It is also forbidden to touch the corrugated air duct with wet hands if it is steel or aluminum, and if the hood is operating at this time.

So, the corrugated system, if we compare it with a rigid channel, is also made taking into account all the requirements of GOST, but it has a lot of advantages: from ease of maintenance to quieter operation, from good tightness to reasonable prices. Finally, it is not difficult to buy such a channel, install it too, and make it so that it adapts to the configuration of the room, and not it to it - more than real.

The comment was sent successfully.