How to choose a lining?

Lining is an environmentally friendly material for decoration, which is made from different varieties of natural wood. With proper care, namely timely varnishing or painting, this material can last an average of 15-20 years.

What it is?

Glued paneling got its name because of its original scope of application: finishing of train carriages. Initially, these were thin wooden slats, but nowadays each slat is equipped with a special lock for ease of installation. Wood is still considered a popular material in the construction industry - it can be found in the decoration of premises, both external and internal, as well as in the construction of houses and any structures. One of the main advantages of wood is the ability to accumulate and evaporate moisture, making the temperature and humidity graphs softer.

Lining, as a finishing material, has a lot of advantages:

- convenient installation due to a well-thought-out system of fastening and connection of parts with each other;

- a large selection of colors, sizes and materials from which the lining itself is made;

- a light weight;

- wide scope of application;

- democratic cost.

Manufacturing

The production of lining is divided into stages and begins with the release of edged boards. With the help of the sawmill, the necessary workpieces are cut, corresponding to precisely specified parameters and dimensions, while using the material of the best purity: between the bark and the core of the tree trunk. The next stage is drying - it is on it that the correctness of the geometric dimensions of the material and their stability depend. During drying, all microorganisms located both inside and on the surface of the wood are destroyed, excess moisture is removed, which reduces the weight of the material and simplifies its further processing.

The final stage is the final processing of the front side and chamfering, after which you get a perfectly smooth and even board. Some unscrupulous manufacturers often neglect this stage, not bothering themselves with high-quality grinding and removing knots that may fall out. Also, dishonest manufacturers often do not finish drying the board, which is why the buyer has huge problems: the lining begins to change geometry, bend, respectively, further use is impossible.

Types and characteristics

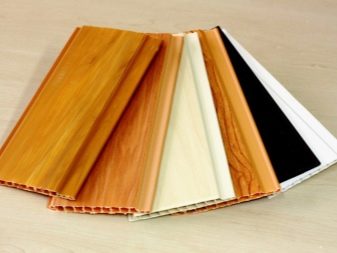

The lining can be either classic, made of wood, or created from materials of a completely different class, such as plastic or MDF. Plastic lining. The type of finish used with this material is also called panel finish. This type of finishing material is extremely resistant to moisture, very light in comparison with analogues and does not lose its appearance under the influence of sunlight, however, due to exposure to low temperatures, it often becomes fragile, and it becomes extremely easy to damage the panel.

The plastic lining is approximately 2-3 times wider than the ordinary wooden version. Its installation simplifies its ability to bend around corners, both internal and external - you just need to cut out a small number of stiffening ribs from the inside of the panel and heat it. In addition, such material can have any pattern, both stylized as a tree, and any pattern or even a whole image, which will be folded from panels.

But still, it should be remembered that plastic is not an environmentally friendly material, so you need to carefully choose high-quality panels so that they do not release harmful substances into the air under the influence of the sun and temperature changes.

Lining from MDF. Panels made of MDF are an absolutely environmentally friendly and clean finishing material that competes well with plastic panels or classic wood paneling.

MDF panels are produced by pressing small and dry wood shavings under the influence of high temperature, while using high pressure for forming. The bonding of the material is carried out by separating a natural substance present in the wood - lignin. Thanks to this, MDF is an absolutely safe material that does not emit harmful substances, since epoxy resins are not used in its production.

Of the characteristics of this type of product, it should be noted the variety of patterns and stylizations for various materials.

Lining made of wood is the most common type of finishing material. She was the very first to appear on the building products market.

Wooden lining has many design styles, but in appearance it can be divided into two types:

- with flat front panel;

- with a rounded front panel that imitates the structure of a bar.

Types of wood:

- Aspen is a light, hard wood that is not prone to cracking and is lightweight.

- Pine - wood of medium strength, rather heavy, has a yellowish and sometimes red tint. It gets a little darker over time. When processing with specialized means, pine lining perfectly resists fungi and mold, as well as insects.

- Larch is a durable wood that practically does not change its size under the influence of external factors; the color range can vary: from light yellow to red-brown.

- Cedar is a very durable and expensive wood. It has a pleasant aroma and beneficial resins, which are endowed with healing properties.

- Spruce is a light yellow wood, similar in properties to pine, but less common.

Advantages and disadvantages of the material

The best properties belong to larch, pine, cedar, spruce and aspen lining. Euro lining, made of softwood, is used for all types of finishes: both external and internal. However, the material made of hardwood is only suitable for installation inside, as it does not tolerate moisture.

Conifers always contain a large amount of natural resins and oils, due to which they can be used in high humidity and resist the formation of mold. This material is suitable for interior decoration, but it cannot be used for cladding saunas and baths - due to high temperatures, resin is released, so the material is covered with its sticky layer and at the same time it can even ignite and start a fire on its own. Therefore, before revealing a sauna or bath with coniferous clapboard, you should rid the boards of resin - this is done in some European countries.

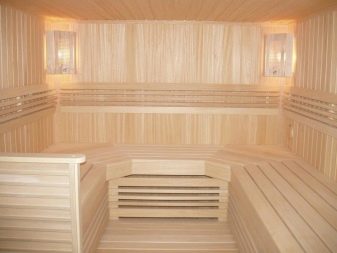

Hardwood, such as linden, alder, oak or ash, has a shorter service life, but does not contain a large amount of resins, and therefore does not emit them, which is why it can be used in baths and saunas. Hardwood lining requires regular and timely processing, otherwise the surface loses its proper appearance and turns black. It should be added that only wood with a low density can be used for baths and saunas, since it transfers heat less and, accordingly, heats up.

Lining for sale in packs of 1 m2. A metal mesh is usually wrapped around it.

Dimensions (edit)

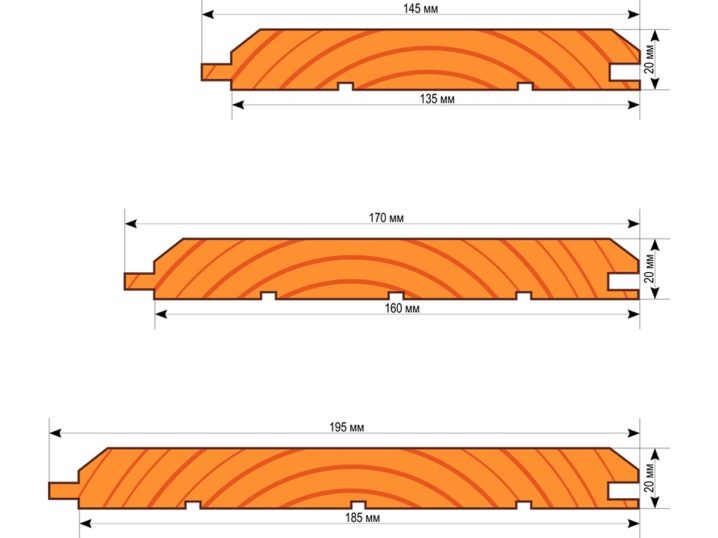

It should be noted that eurolining and ordinary lining have different sizes, which are often indicated in tables on manufacturers' websites.The dimensions of an ordinary lining are set directly by the manufacturer of the material, but there are the most popular parameters that have become the standard.

The dimensions of the wooden lining can vary widely:

- thickness - from 12 to 40 mm;

- width - from 76 to 200 mm;

- board length - from 20 cm to 600 cm;

- spike height - 4-5 mm.

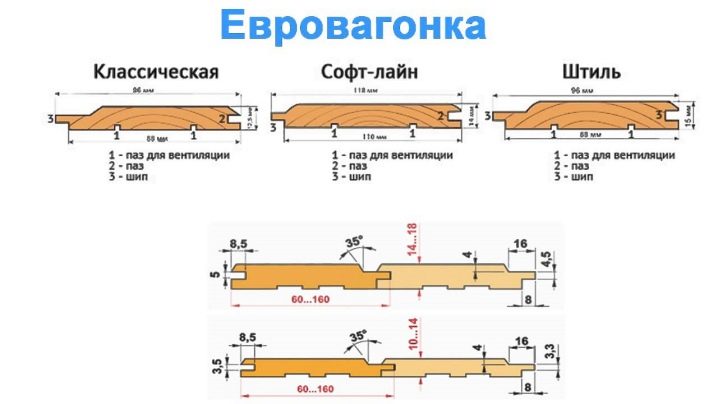

Euro lining dimensions

For euro lining, more standardized parameters are inherent:

- thickness - 13, 16, 19 mm;

- width - 80, 100, 110, 120 mm;

- board length - 50-600 cm;

- spike height - 8-9 mm.

Possible errors:

- thickness - up to 1 mm;

- width - up to 1 mm;

- length - up to 5 mm;

- spike height - up to 0.5 mm.

It should be mentioned that short lining boards have a much lower price. This is because small lengths are often scraps from the final finishing of long boards. The reason is that on long parts during the finishing process, you can see dead knots that need to be removed, as they can fall out during use - this will preserve the type of lining.

What are the differences between varieties?

Various types of lining are used in the decoration. Below is a description of each class.

There are 4 classes:

- class "Extra";

- class A;

- class B;

- class C.

To category "Extra" includes a light-colored, knot-free board. The board in this class is completely free of cracks, chips and other defects. The moisture content of this type of product should not exceed or be lower than standard values by 12-14%. The "Extra" class implies the highest quality of the material - it can be easily used for decoration of residential premises. The boards are extremely carefully processed and have a pleasant appearance without flaws.

V class "A" includes boards of light color, on the surface of which there may be small amounts of knots, resinous areas, cracks and chips. However, their presence does not significantly affect the strength of the board. The moisture content of the material should not exceed or be lower than standard values by 12-14% percent. Also suitable for interior decoration.

V class "B" includes boards of a dark color, which are often characterized by the presence of knots, chips, cracks and other defects. But at the same time, their number should be no more than 20%. The size of the resin areas should not exceed 15 cm. The moisture content of the material in this grade should also be within standard values with a deviation of up to 12-14%.

V class "C" includes the lowest quality boards in various colors. Defects can occupy up to 30% of the entire board area. The material of this grade is devoid of finishing, therefore indoor installation is undesirable. This type of lining is used for exterior decoration.

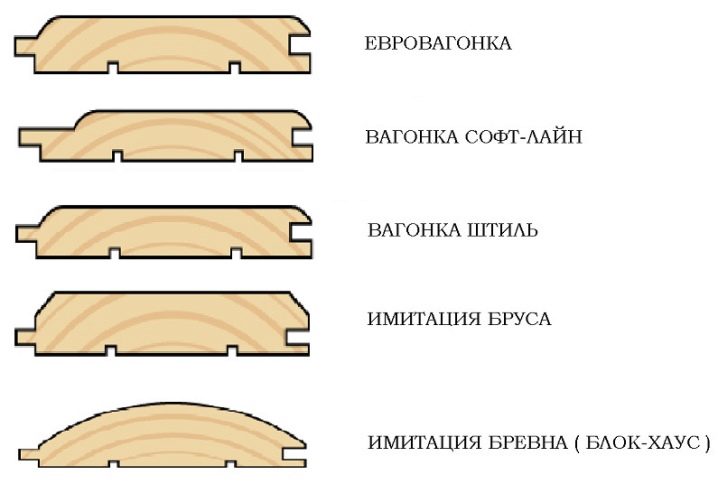

Types of lining profiles

It should be mentioned that only wooden lining has a varied number of profiles - other types are made in a standard profile.

Profile of the "Standard" type. The front side of the board is flat and its edges are beveled at an angle of about 30 degrees. The edges of the board have special grooves and protrusions of the "thorn-groove" type for a reliable connection to each other. At the same time, the height of the spike is made slightly less than the depth of the groove in order to compensate for thermal expansion and to take into account production errors, as well as to make it possible to fasten boards of different parties together.

Calm profile. This type of wooden lining differs from the classic only in the rounded corners of the boards. Otherwise, the product is completely similar to the standard version, but at the same time it looks better than the classic lining with its sharp edges.

American profile. This type of profile has a front part with beveled edges, due to which the effect of overlapping boards appears during installation.

Euro lining. Unlike ordinary, familiar Euro lining has a thicker spike, which guarantees greater reliability and durability of the finish during operation.In addition, after installation, the lining forms a solid pattern, and not chaotic, as is the case with the classic version. Such material is quite easy to lay and, if necessary, can be painted with acrylic paint with your own hands.

This material is manufactured according to the European DIN standard. Eurostandard obliges the manufacturer to adhere to extremely stringent requirements for moisture and wood quality, board geometry and thoroughness of finishing and finishing. Also, Euro lining boards have two grooves or grooves on the back side, which serve to drain condensate and ventilate the space between the sheathing and the wall. This protects both the board and the crate with insulation from rotting and the appearance of fungus or mold as a result.

Also, such grooves somewhat help the boards withstand thermal expansion and changes in the geometry of the material due to changes in humidity.

Selection Tips

Before choosing a product, first of all, you should decide on the lining material. Wooden lining has long established itself on the market as an affordable and reliable material for interior decoration. Of the positive qualities of wood, it should be noted good sound and heat insulation, as well as the convenience of working with the product itself. Wooden lining has a wide range of applications: it is used for sheathing both baths and living rooms, both inside and outside.

Lining made of wood can be made from different types of wood, respectively, they all have a separation by properties. When choosing a wooden lining, attention should be paid only to the euro lining. The main difference is quality. A thicker lock, high requirements for wood and its moisture content, as well as surface treatment make the Euro lining incomparable in quality with the usual version. However, if you need to save a budget, then the classic lining is also a good option. But you should closely monitor the quality when choosing a material, and also be prepared for difficulties in the form of a poorly connecting lock, a rough surface, falling out knots and possible cracks if the installation is carried out in a damp room.

Fasten the wooden lining with clamps. A kleimer is a bracket that is attached to the crate with nails or self-tapping screws and presses the lining lock to the base, but at the same time itself is not rigidly fixed to the board. This allows the lining to change its dimensions without problems due to thermal expansion and humidity and move vertically, which guarantees the reliability of the fastening and the absence of cracks or extraneous sounds in the future.

Separately, it is worth noting such a scope of lining, as finishing baths and saunas. Coniferous lining is rarely used in baths, as it can release resin, but this helps it to resist aggressive conditions, such as changes in temperature and humidity, as well as fungi and microorganisms. In saunas and baths, alder or linden lining is most often used - such wood, after processing, does not emit tar at all. Hardwood lining has a shorter service life due to the porous structure of the material, but thanks to the same porosity, this wood can withstand high temperatures.

Plastic panels appeared on the market not so long ago, however, have gained a good reputation. They are not suitable for external decoration, but are great for cladding loggias and bathrooms or showers. Since plastic is insensitive to water, the panels can withstand any humidity and are also insensitive to sunlight. Unlike wood, plastic lining can have any pattern or pattern that repeats wood or stone. You just have to beware of low-quality panels, which, at the slightest drop in temperature, become extremely fragile due to the fact that the manufacturer saves on the quality of plastic.

MDF lining is laminated, veneered and painted. Laminated options are covered with PVC film, have a lower price and are more wear-resistant than veneered ones, which are covered with premium wood veneers. Painted panels, as the name implies, have a uniform color. Overall, this is a good alternative to the previous options. MDF lining has all the advantages of a wooden version and is produced in a wide range of colors. This alternative is suitable for the entire apartment - it can be used both in the kitchen and in the corridor, using it in the wall or ceiling cladding.

It is imperative to monitor the quality of the material when choosing it: the surface of the product should be even and smooth, uniform in color, without darkening and cracks. Do not trust the exhibition samples, as the sample may be from a different batch, or the lining could be stored in unheated and damp rooms. Unfortunately, it is impossible to know exactly the quality of storage of the material, therefore, as an option, you can buy one or two packs of material and see what will happen to it at the installation site.

Care

The lining practically does not require maintenance - you just need to pay attention to it during installation: if the material for making the lining is wood, then you should cover it with varnish or paint. Lining of other types does not require such manipulations.

It is important to know that you should not wet the wooden lining unnecessarily when cleaning or cleaning - the wood readily absorbs moisture. Under no circumstances should abrasive materials be used to clean the panels - this may damage the pattern.

Beautiful examples of finishing

The exterior decoration of the building with a wooden clapboard with the "American" profile looks stylish and beautiful.

Decorating a sauna with linden lining is an expensive cladding option that will immediately indicate to guests the status of the owner of the room.

Decorating the room with PVC plastic panels in the interior looks very stylish and emphasizes the main design of the room. Combined with white, this setting can be even more inviting.

You will learn about what mistakes should be avoided when choosing a euro lining in the following video.

The comment was sent successfully.