Standard sizes of eurolining

Modern lining has a beautiful durable coating, which allows it to be used in various fields. Boards are actively used in the decoration of facades and for interior cladding of premises. They can be manufactured using various technologies. You can highlight the lining and eurolining. The latter option has a different thickness, differs in appearance and groove connection.

The difference between lining and eurolining

There are some differences between these two finishing materials.

- The lining has a low level of humidity. Only 12%, and for ordinary lining, a value of 15 to 20% is acceptable.

- Euro lining is characterized by strict compliance with quality standards.

- The front surface of the Euro lining is perfectly smooth.

- To pack the lining, plastic wrap is used.

- A large number of ventilation ducts are concentrated in the lining, through which the formed condensate is discharged. The same grooves allow you to remove internal stress.

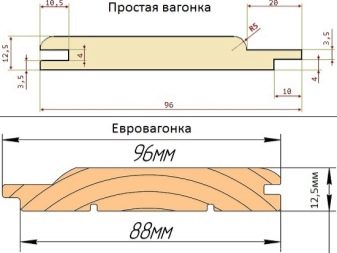

- In euro lining, the groove has a size of 9 mm, while in ordinary lining it is 5 mm.

- Conventional lining is characterized by the complexity of the installation, for which specialists are often called in. When it comes to the installation of euro lining, then it is quite possible to cope here on your own.

Varieties and varieties of eurolining made of wood

Wooden Euro lining can be classified according to the production profile.

There are two profiles on the market today.

- The standard, which can be referred to as an ordinary lining, "collective farmer" or "classic". A special feature of this finishing material is the minimum number of grooves, which are practically absent.

- The lining has a similar appearance to the previous profile, however, more stringent requirements are imposed on this material. In addition to them, when joining the lamellas in this case, there is always a slight groove. In some situations, it reaches up to 15 mm.

We will present the most common types of Euro lining, which are characterized by a vertical fastening method.

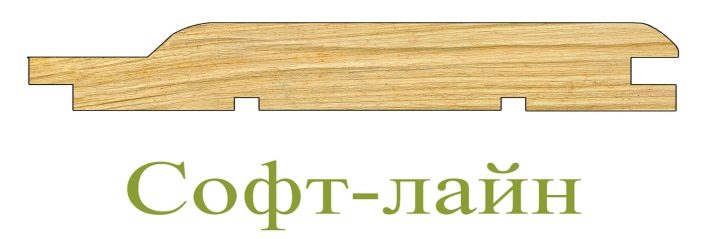

- Softline - a view where the boards are slightly rounded. The width and length of the material allows you to quickly carry out facade finishing.

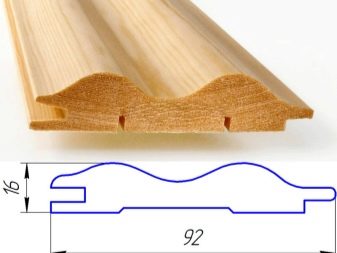

- Wave is a type of Euro-lining, in which the front side is slightly concave.

Other types of wooden lining can be distinguished, which differ in the horizontal method of fastening.

There are several varieties worth paying attention to here.

- American. With the help of the type of euro lining under consideration, you can simulate the laying of wood planks. Most often used for outdoor decoration. Euro lining is characterized by protection in the area of joints, where moisture cannot get. Since these panels can be purchased in various widths, the cladding of the house can be done as quickly as possible.

- Imitation of a bar. In this situation, the lining has a standard profile.

- Block house. If the building is finished with this material, it will look like a log house. They differ in different lengths and widths, so finishing is quite simple.

Euro lining dimensions

You should pay attention to the following factors:

- lining can have a length of 0.5 to 6 meters;

- on the market you can find the boards under consideration with a thickness of 13, 16 and 19 mm;

- the width of the euro lining can be 80, 100, 110 and 120 mm, these dimensions are optimal for facing works in large rooms;

- the size of the spike can vary from 8 to 9 mm.

What deviations are optimal?

The following permissible deviations can be distinguished:

- in length, a maximum difference of 5 mm is permissible;

- in thickness - 0.7 mm;

- in width - 1 mm;

- in the size of the thorn - 0.5 mm.

Due to the optimal dimensions of the lamellas, gaps will not form when working with wooden Euro lining. At the same time, the material will not lose its appearance, which is extremely important in the issue of wall cladding.

The existing dimensions of the Euro lining are designed to facilitate the process of surface cladding with panels.

Advantages and disadvantages

Today, eurolining acts as a fairly popular finishing material. The high demand for euro lining was formed due to the many advantages that many other types of finishing materials cannot demonstrate.

Several factors are worth highlighting among the main advantages.

- The most affordable material for finishing is a wooden euro lining made of linden.

- Environmental friendliness is guaranteed.

- The material in question has a beautiful appearance. Any wood used is unique. Customers have the opportunity to choose from a wide range of shades and textures to create unique interior designs.

- The material acts as an excellent heat and sound insulation.

- The lining will be used for a long period, especially if it is properly cared for. It is able to serve its owners for up to 50 years, while maintaining its original unique look.

- Wooden Euro lining is characterized by ease of installation, which is possible due to the presence of a ridge and grooves. With the help of these panels, you can perform cladding as soon as possible, and you do not need to be a professional in this area to perform these works.

- With the help of euro lining, you can make additional finishing.

- Today you can purchase different sizes of eurolining made of wood, which are most suitable for a particular room, based on the surface area that needs to be sheathed.

Despite the impressive list of advantages of the material in question, the euro lining also has disadvantages, but there are very few of them.

Several indicators act as negative sides.

- When using euro lining made of wood, there is a risk that it will deform. This mainly depends on the type of wood you have chosen for the cladding.

- The material in question does not cope well with temperature fluctuations and is sensitive to high humidity, however, these parameters also depend on what kind of wood the boards are made of.

- It should be emphasized that the disadvantages mentioned earlier do not appear to be catastrophic, since they can be neutralized through the use of special processing of the boards and high-quality installation.

If you want to purchase euro lining, you need to know exactly in what conditions it will be used. For example, it will be installed in rooms with high humidity. In such a case, it is important to pay attention to conifers. When it comes to cladding dry rooms, deciduous wood planks may work.

You need to immediately determine the optimal size of the purchased panels. If the room has relatively small dimensions, it is better to pay attention to the panels that have a small width. When decorating large rooms, it is worth opting for a material with a large width of boards, as this will facilitate the sheathing process.

What is the best lining to choose?

In order not to make a mistake in choosing a euro lining, you should pay attention to many parameters.

- The quality and type of wood used. To do this, you need to familiarize yourself with the properties that this or that type of wood has. It is necessary to choose depending on the conditions in which the material will be used.

- Euro lining length, which directly affects its value. The longer the board is, the more expensive the material will be.

- Drying quality. The panels must be well dried. For example, the lining should contain no more than 12% moisture. Only then can it be considered ready for use. You can measure moisture using a special device.

- Features of woodworking. If the panels were manufactured using modern equipment, then the deviation from the standard indicators will be minimal. It should be borne in mind that today customers can purchase eurolining made of solid or spliced wood. Each of the options under consideration has its own specific advantages. Solid wood is characterized by an attractive appearance, but the cost of such a material is quite high. In the case of a spliced Euro lining, seams are visible, but this does not affect the quality in any way.

- Grade. Here you need to pay attention to the type of wood from which the boards are made.

- Storage. The lining must be stored in a closed, dry place that has good ventilation. Unfortunately, many sellers of this material leave the boards outdoors, where they are exposed to moisture and ultraviolet radiation. Note the presence of blue. If there is one, then this indicates that the wood is infected with a fungus.

- Manufacturer. Experts recommend giving preference to manufacturers from the northern regions of the country, which is due to the climatic conditions where the raw materials for this material grow.

It is important to note that you have the opportunity to purchase eurolining from another material, for example, plastic, however, over the years of operation, wood has proven itself exclusively from the good side. Using this natural material, you can create a unique interior design, while you can be sure that the boards used for cladding will serve you for more than one year.

The installation process of the euro lining is shown in the following video.

The comment was sent successfully.