All About Rubber Paving Slabs

Safety of movement is the main requirement for paths in playgrounds, rest homes, sanatoriums, hospitals. And on the local area you always want to feel confident. Modern track pavements come in a very wide range and there are many different options to choose from. The newfangled trend is rubber paving slabs, all of which you can learn from this article.

Peculiarities

The main material of such a tile is crushed rubber crumb obtained from recycled car tires. Its composition is 90%, the rest of the components are coloring substances and a polymer binder. During production, a compressed web is obtained, which is then cut into the desired shape and configuration. Rubberized slabs are placed on a variety of surfaces: soil, sand, self-leveling floors and more, the main thing is that the laying area is flat.

In this case, the polymer substance contributes to the improvement of adhesion. Thanks to him, there are no seams on the finished coating.

Rubber paving slabs have many positive qualities..

- Security... Unlike ordinary asphalt, rubber tiles soften shocks, so it doesn't hurt to fall on them. This is why this type of flooring is often found in playgrounds. In addition, the tile reduces the likelihood of falling into ice or snow, as it has anti-slip properties.

- Convenience... The rubber coating is soft, which means it helps to relax. These tiles are often found in rooms equipped for meditation and yoga. And rubber covers are also used in fitness centers, as they dampen footsteps and create comfort for those who go in for sports.

- Resistance to negative weather conditions. Paving slabs made of crumb rubber have increased resistance to frost (up to -40 degrees), they are not afraid of exposure to ultraviolet radiation. In addition, due to its porous surface, the coating quickly gets rid of moisture.

- Resistance to germs and weeds... Mold and mildew do not form on the rubber tile, it does not rot. Weed grasses also have no chance of germinating through the cover.

- Durability... Rubber pavement, with proper care, will serve for decades without needing to be updated. The dyes used for the coating do not fade in the sun.

- A large assortment. Today, the choice of such tiles is very wide: there are different shapes, colors, sizes, ornaments. Everyone will find something for their taste and budget.

- Ease of styling... Paving rubber tiles can be installed as easy as shelling pears, for this you do not need to call specialists. In addition, in most cases, it does not need hardening, drying and other similar procedures.

As you can see, the list of advantages of rubber crumb paving slabs is very extensive. But before buying it, it is important to remember the cons.

- Flammability... Rubber tiles burn very well. Therefore, you should not put such a covering in an area where you are used to barbecue or light a fire.

- High rates. This sidewalk covering is one of the most expensive, and not everyone can afford it. Nevertheless, there is a benefit from the purchase, since you will not have to think about updating the coverage and spending money on it for a very long time.

Manufacturing technology

As already mentioned, the main material for the production of rubber paving slabs is car tires sent for recycling. They are cut into strips, then into squares, crushed and thus receive crumb. This material is mixed with adhesive and coloring additives. Then the process itself begins, which is hot or cold pressing. Let's consider both techniques in more detail.

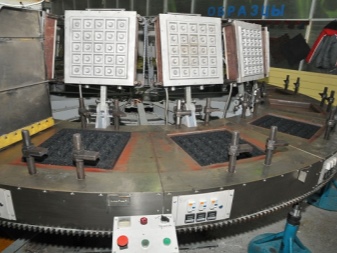

Hot pressing

Using this method, you can create a relatively cheap and aesthetic tile, but the method is not very popular. The resulting tiles are not frost-resistant, and therefore such a product can be sold only in those regions where a stable climate without severe cold weather.

The process looks like this:

- raw materials are being prepared;

- is poured into special molds and sent under a hot press with a pressure of more than 5 tons;

- the press heats up the crumb, shaping it.

Cold

This is a more costly process in terms of money and effort, but the resulting tile will meet all safety and comfort requirements. Cold pressing is carried out as follows:

- raw materials are made, while more glue is added to it than with hot pressing;

- raw materials are poured into molds, then placed under a cold volcanic press with the same pressure as in the previous method;

- after pressing, the mixture is placed in special equipment - a heating cabinet, where it is kept for about 6-7 hours at a temperature of 60 degrees;

- the resulting tile is finally dried at room temperature.

Views

Rubber tiles can be different in size, appearance, color, shape. There are several main classifications.

- By thickness and fraction... These are single layer and double layer options. Single-layer tiles are 1-4 cm thick and are used here with fine or medium chips. The thickness of a two-layer tile starts from 3 cm. The upper layer consists of small colored chips, the lower one - of large and unpainted ones. Thanks to this, two-layer tiles are more profitable, since they are able to withstand significant loads.

- By invoice... There are both smooth rubber plates and embossed ones. The former are recommended to be installed on large areas, the latter will be more decorative and will ennoble the recreation area. In addition, embossed slabs are good from a practical point of view: they slip less in rain and ice, so the risk of falling is minimized.

- To size. Here, the tiles can be completely different. For example, there are small options, 50x50 cm, and there are large ones - 100x100. The latter are more variable: these are simple forms such as a square, and more complex paving stones in the form of a puzzle, spiral, wave.

Applications

Rubber paving slabs are used in a variety of situations:

- at playgrounds, in play and sports areas, at stadiums;

- on pedestrian paths where there is a constant flow of people, for example, it can be parks, squares, city squares;

- in gyms, relaxation and recreation rooms, in areas adjacent to sanatoriums, hospitals, hotels;

- in the area near the pool to prevent slipping on wet floors, in spas, beauty salons;

- in parking lots and exits from them, in car repair shops, in service centers;

- in the premises of a warehouse and production, in factories, factories;

- in buildings where animals, birds, fish will have to be placed for a long time;

- in the country for arranging the sidewalk or path, recreation area;

- on the steps of stairs to shops, salons, workshops and other service centers.

It is not recommended to install paving rubber tiles in places where there is an increased risk of fire. In addition, if the coating is placed on a staircase, it is worth choosing only its corrugated version.

The subtleties of styling

Paving slabs made of crumb rubber can be laid on different types of bases, the allowed level deviation is 1 mm.If the tiles are laid in large open areas, then it is important to provide a slope of 2 degrees so that the waste water can drain off without problems. Before starting work, the base on which the coating is to be laid is checked for cracks and pits. They will need to be removed. In addition, a moisture test must be done. For this, the base is covered with table salt and waited for two days. If the salt remains dry, you can start work.

For the correct laying of rubberized tiles, the following materials and tools must be prepared:

- the tile itself;

- container for adhesive;

- polyurethane glue;

- soap solution;

- a small piece of chalk;

- a ruler, a building level and a knife, a spatula with teeth;

- dishwashing sponge;

- broom (you can take a vacuum cleaner instead).

In addition, it is necessary to take into account external conditions:

- the day should be warm, at least 15, but not more than 25 degrees, and dry;

- permissible air humidity should be no more than 70%;

- if the tile is laid in an open area and will be exposed to contact with snow and rain, the glue is applied in two layers.

Now let's look at how you can lay tiles on the ground and on concrete.

On the ground

Consider the process of laying rubberized tiles on the ground.

- The base is cleaned of dirt and debris, is brought to an even state, compacted.

- Crushed stone is poured on top, the thickness of the backfill depends on the situation. Walkways for the local area will require 70 mm, play areas for children - 100, areas intended for car parks - 200 mm.

- Take 1 part of cement and mix with 3 parts of sand - this is the second layer. Its thickness is 70 mm.

- Special rubber curbs are installed around the work area. Thanks to them, it will be possible to clearly apply the bedding.

- Tiles are laid out, while continuous control should be exercised to ensure that the rows lie flat. The plates are joined with the help of a sleeve, while a rubber hammer will help if the tile does not lie flat. If there is room between the curb and the tile, it can be filled with scraps from the tiles themselves, cut with a knife.

- The coating is rammed and covered with sand from above.

On concrete

It is even easier to lay tiles on concrete, we will analyze the process in stages:

- the concrete base is well swept or vacuumed;

- using a spatula, glue is applied to concrete blocks, and it is important that it is distributed in an even layer;

- laying the tiles starts from the middle of the treated area (tile thickness - 20 mm), while the coating is firmly pressed to the base;

- each subsequent tile is laid close to the finished one, all the glue protruding to the surface is immediately removed;

- the coating dries for 48 hours - only after this time you can walk on it.

Care rules

Good paving slabs serve for many years and do not lose their attractive appearance. She does not deform from snow and rain, she is not afraid of the sun. It would seem that it is not necessary to take care of her at all, but this is not so. There are still a few rules.

- A dirty surface can be quickly and easily cleaned with water from a hose, while maintaining a medium pressure is sufficient. If the stains are dry and cannot be affected by the liquid, they can be removed with a stiff brush dipped in soapy water.

- The icy coating is freed with a shovel or ice ax, freshly fallen snow is swept away with a broom.

If there is a large area of paving slabs, it can be processed with a snow blower.

The comment was sent successfully.