Varieties of concrete paving slabs and their characteristics

The design of sidewalks, house plots is usually done with the use of high-quality concrete slabs. It is important that they are not only aesthetically pleasing, but also durable, with a long service life.

There are special technologies that make it possible to produce tiles according to certain standards and with appropriate labeling.

Peculiarities

Concrete paving slabs can be seen literally everywhere, as they are practical and easily complement the landscape design. You can often find paths in courtyards and entire adjoining territories, laid out in neat blocks. It is convenient to design entrances to buildings, paths for pedestrians and cyclists, sidewalks using concrete slabs.

On the streets, very often with the help of concrete elements, pedestrian crossings (underground and ground), public transport stops, paths in parking lots, squares are covered. A also sidewalk tiles with a non-slip coating can be found in children's playgrounds, and multi-colored, with unusual shapes - in the decor of flower beds and flower beds.

Such widespread use of this type of finishing material is due to its advantages:

-

low cost, which makes the tile available to many consumers;

-

ease of installation allows, if desired, to do all the work yourself;

-

resistance to wear ensures a long service life of products;

-

good water resistance;

-

if necessary, repairs can be made fragmentarily;

-

resistance to temperature extremes;

-

aesthetic appearance;

-

variety in size, shape and color.

For many climates, an important point in favor of concrete tiles is easy maintenance in case of frequent rainfall. It is enough to organize the flow of water along the gaps between the joints in the blocks so that it can be absorbed into the soil. Modern concrete products for surface finishing are produced only in accordance with the specified GOSTs. Usually, heavy or fine-grained concrete in several layers is used for production. In this case, the thickness of the upper layer is more than 2 millimeters.

According to the standards, moisture absorption should not exceed 6%, and strength should not exceed 3 MPa. With regard to wear, it does not exceed 0.7 grams per square centimeter. It is also assumed that the tile can easily withstand more than 200 stages of freezing and thawing.

If the thickness of the tile allows, then it is not reinforced. With wire in the form of reinforcement, products with a thickness of 7.5 cm or more are produced.

The elements are lifted and transported using mounting loops with a diameter of 6 mm.

How are slabs made?

The production of concrete tiles is carried out in several ways.

-

Vibration casting implies that the tile is obtained by casting in special molds. As a result, the material will have a smooth surface. However, in this case, the resulting product will be less durable, and the resistance to low temperatures will decrease. This reduces the service life to about 10 years.

- Vibrocompression carried out also with the help of the press. Tiles made by this method are characterized by resistance to temperature fluctuations. They also tolerate mechanical damage better. Thus, the tiles obtained by vibrocompression can last 25 years or more.

To better understand what a concrete tile is, you should familiarize yourself in more detail with the process of obtaining it. The production of concrete elements usually takes place on a vibrating table. This allows you to give the base material strength. Of course, in addition to concrete and a table, you will need additives to give the products waterproofing properties, coloring pigments, and special shapes.

Workpieces are installed on the vibrating table, which are pre-lubricated with oil. This is necessary to make ready-made concrete slabs easier to obtain. The mixture is poured into each mold. After passing the vibration casting process, the workpieces are removed from the table and transferred to the shelves.

Here they are covered with polyethylene and left for several days (no more than 3).

However, the concrete will fully harden only after 21 days.

Concrete products are removed from the molds using a device that looks like a hammer. However, it is important to apply light blows so that cracks do not go through the slab. Otherwise, it will become unsuitable for use. Of course, it is best to use plastic molds, which will surely keep the concrete intact when removed.

After that, the plates need a couple more days to lie down. This is due to the fact that concrete has the ability to expand. If there is a need to make the plates as strong as possible, then metal elements can be added to the forms as reinforcement. For some types of slabs, they even use special frames of increased strength.

Description of species

Concrete slabs can be divided into two main types: sidewalk and road.

-

Sidewalk are used to decorate pedestrian paths and other places with light loads.

-

Road reinforced concrete are applicable when blocking roads, car parks, entrances. Usually such tiles are reinforced for reinforcement. As a result, they can be used wherever massive heavy equipment passes.

Most often, the road slab is gray, since there is no need for color aesthetics for it. As for sidewalk blocks, their color can be quite varied depending on the dye added during manufacture.

On the upper surface, the slabs can be either smooth or rough.

By form

The shape of the tiles is classified according to the standards and marked accordingly.

-

Rectangular ones are made in the form of a classic rectangle and are designated by the letter "P".

-

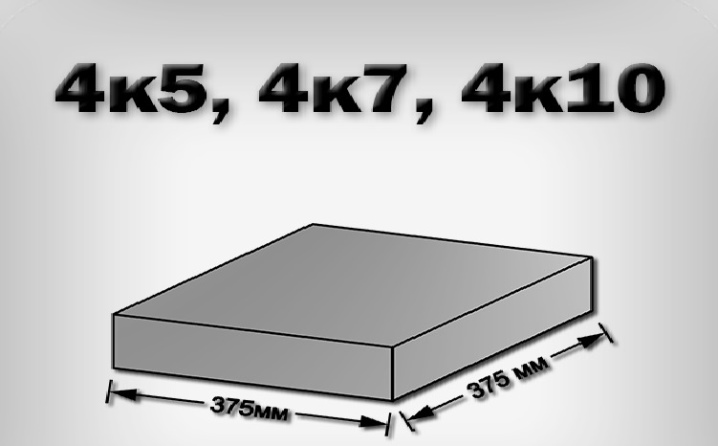

Square, as the name implies, has all the properties of a square. The letter "K" was chosen for their marking.

-

Hexagonal ones are usually marked with the letter "W".

-

Curly ones can have an intricate look. You can recognize them by the "F" marker.

-

Framing is easy to identify by the designation "O".

-

Decorative road elements are labeled in a slightly more complex way - with three letters "EDD" at once.

It is worth noting that there is a separate type of coverage designed for places used by visually impaired people.

Such slabs are convex and have rough protruding elements that the pedestrian can feel with their feet. It is better to choose the form of coverage in advance, while taking into account the future load on it.

And also there is an unspoken division of paving slabs in shape, understandable to manufacturers and buyers. Among them, the most widespread are such types as paving stones (brick), wave, honeycomb, clover, coil, scales, flower, cobweb, fleece and others.

By appointment

Slabs can be divided into two classes:

-

for temporary pavement it is designated "2P";

-

for permanent road surface it is marked as "1P".

These types have different fastening methods and composition.

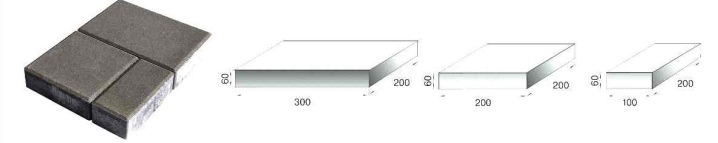

Designations and dimensions

Concrete slabs for roads usually vary in length from 3 to 6 meters, and in width from 1.2 to 2 meters. As for their height, it ranges from 14 to 22 centimeters.

Sidewalk slabs come in a wide variety of sizes. For example, blocks in the form of squares can have parameters of 100 by 100 mm or 20 by 20 cm, but the most common variant is 50x50 cm. As for the thickness, it depends entirely on what the coating will be used for. For example, slabs with a height of 40-60 mm are used for ordinary pedestrian needs.If you need to withstand an increased load, then it is better to choose blocks with a thickness of 70 mm or more.

If we proceed from the height, then 100x200x30 mm slabs are sufficient for park and garden paths, 300x300x40 mm for pedestrian zones or for the sidewalk. Highways, especially if not only cars, but also freight vehicles move along them, can be covered with blocks with such parameters as 500x500x50, 500x500x70 and even 300x300x50 mm.

Of course, for places with a high load, reinforced plates with parameters 1000x1000 mm and a height of 100 mm will be an ideal solution.

It should be borne in mind that a parameter such as the height of the slab also affects the installation method. So, for tiles with a thickness of 30 mm or less, it is necessary to pre-fill with concrete.

The weight of the blocks depends on their size and shape. For example, the mass of an eight-shaped tile with a size of 400x400 mm will weigh a little more than 18 kg, and a square of 500x500 mm will weigh 34 kg. A lighter turtle is with parameters 300x300x30 mm - 6 kg.

The brands allow you to distinguish a huge variety of concrete paving slabs. Designations include letters and numbers, which are usually written with a dot. The first number in the marking indicates the standard size number, the letter indicates the product type, and the second indicates the block height, measured in centimeters. As an example, we can consider how the designation of a square slab with parameters 375 by 375 mm and a height of 7 cm is formed. So, the first will be the number 4, followed by the letter "K", and then the number 7 - as a result, a marker of the form "4. K. 7 ".

Installation rules

Correct installation of paving slabs ensures long-term and pleasant operation of the coating. The blocks are laid on different bases depending on the load on the surface. For example, for walking paths, it is enough to make a cushion of sand. If the coating will also be used for transport, then concrete mortar cannot be dispensed with.

Tiles can be laid in various patterns. The most popular among them are the herringbone, wicker, semicircle, brick, posts. Installation consists of certain stages.

-

The site is marked with paths and sidewalks.

-

The top layer of soil measuring 150 mm is removed.

-

The opened soil is carefully tamped.

-

Next, you need to form grooves for water drainage and fill them with 5 cm of sand.

-

Now you need to create a pillow of wet sand, crushed stone and concrete 100 mm high. It must be tamped down with a rubber mallet or vibrating plate.

-

When the base is ready, the tiles are laid at a distance of at least 3-5 mm from each other. The resulting seams can be repaired with the same compound from which the pillow was made.

-

The final stage is cleaning the canvas with water, which is directed along the cracks.

During installation, it should be borne in mind that some of the concrete elements will have to be cut to level the masonry.

Therefore, it is advisable to purchase tiles with a margin. A lower consumption of blocks can be obtained if the laying is done in more economical ways, for example, straight, rather than diagonal.

The comment was sent successfully.