All about the curved vice

When machining any part, it is necessary to ensure that it is stationary. A vise is used for this purpose. This device is very convenient in two ways at once: it frees the hands and provides a firm fixation without any physical effort.

Vices are different. Curves are one of the most popular varieties.

Features and working principle

The curved vise is a special device that refers to high-precision tooling... There are several differences from conventional devices. The differences are as follows.

- Manufacturing precision.

- Possibility of tilting.

- The base of the case has threaded holes for attaching to all kinds of devices.

- Smaller dimensions.

- High-quality execution of some details.

They are used for various types of work: weaving, drilling, planing and other processing. The main purpose is to securely fix the workpiece.

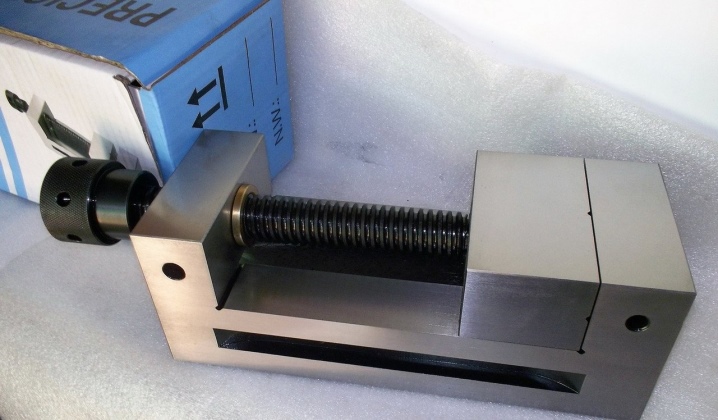

The vise consists of three main parts: clamping screw with swivel handle, jaws and base with base plate. How the device works is as follows - with the help of a screw, the movable platforms are unclenched, the workpiece is placed between two platforms (jaws) and again tightened with a screw.

The vice can be made of two materials - wood and metal. For curved vices, the latter is more often used.

Model overview

There are many varieties of curved vices. The most high-quality and demanded models are as follows.

- An inexpensive, but excellent quality option - Curved precision quick-changeable QKG-25... The device has a jaw with a width of 25 mm and a maximum opening of 22 mm. The cost is about 3 thousand rubles.

- A more expensive option is the QKG-38. The only difference is that the width of the jaws in this case is 38 mm, and the maximum opening is 44 mm. The cost is 3100 rubles.

- Curved precision vice SPZ-63 / 85A. The characteristics are as follows: the jaw width is 63 mm and the maximum opening is 85 mm. The cost is 3700 rubles.

- SPZ100 / 125A machine tools with a jaw width of 88 mm, and an opening of 125 mm. The cost of such a device is on average 11 thousand rubles.

There are also more expensive models, but they are recommended for purchase by professionals, and for home use it is quite possible to do with one of the above options... An alternative to each model presented is a homemade vise.

How to choose?

Before buying a vise for your home, you should decide on the cost... It is not recommended to save on vice. In extreme cases, you should not pay attention to models that cost no more than 3 thousand rubles. Inexpensive models are often of poor quality, so they will quickly become unusable. Also, it will not be very comfortable to work with such a device, since there will be no reliable fixation of the part.

With significant mechanical stress, the workpiece will slip out of the grip, which is fraught with not only its loss, but also injuries for the person who processes it.

You should also decide with the manufacturer. The following companies are engaged in the production of vice: Wilton, Stanley, NEO, Delo Tekhniki, Cobalt, Caliber and some others. Here the choice depends on purely individual preferences. Of course, an important criterion when choosing is device size. It all depends on what parts are planned to be processed.Naturally, small vices simply cannot withstand heavy and bulky parts, and it will be extremely inconvenient to fix small ones in massive vices.

For locksmith vice there is GOST 4045-75... It applies to those models with jaw widths from 63 to 200 mm.

There are also GOSTs 20746-84 and 1651896. In addition, the accuracy class (normal, increased or high) is always indicated - this is also an important factor.

An overview of the vise of curved precision is presented in the following video.

The comment was sent successfully.