What are drill sharpening machines and how to choose them?

All performance indicators of this type of tool directly depend on the sharpness of the drills. Unfortunately, in the process of use, even the highest quality ones inevitably become dull. That is why the relevance of topics related to what modern machines for sharpening drills are and how to choose them correctly is constantly growing.

Peculiarities

Any machine for sharpening drills allows you to simplify the entire process as much as possible and minimize time costs. It is also important to take into account that such sharpening machines allow you to obtain the most accurate geometry of the cutting part of the tool being processed. Taking into account their operational properties, such devices can be safely called indispensable both in production and in everyday life.

One side, at home, a drill that is rarely used can be restored without a special sharpener. However, if drilling work is performed more often, then the purchase of a machine will already be justified.

One of the main advantages of automated grinders is maximum ease of use.

The traditional equipment of the described machines provides for the presence of a stand with a support for fixing the drill to be machined. This device is located next to the abrasive wheel, and its main function is to position the working surfaces of the machined tool at the appropriate angle. In parallel, the working feed of the drill is carried out during its sharpening.

By the way, simplified versions of sharpening equipment are quite effectively used not only in domestic conditions and home workshops, but also in production. Today, the popularity of machine tools equipped with clamping chucks is actively growing. Such models, regardless of the specifics of the application, have the same operating principle. At the same time, the main advantage of the equipment remains the maximum ease of use. Practically no special knowledge and skills are required to perform sharpening.

Device and principle of operation

At its core, the standard design of a drill grinder is simple enough that the equipment works almost flawlessly and boasts a maximum service life. Modern sharpeners are made up of these components.

- The body of the device, which houses its power plant (electric motor). By the way, the power of the latter is selected taking into account what kind of hardness materials will be processed on the machine. In parallel, it should be borne in mind that the speed of rotation of the sharpening elements directly depends on the power of the motor, and therefore the time spent on performing the necessary work.

- Abrasive wheels parallel to each other, which can be made of different materials. So, for processing drills made of hard alloys, as a rule, diamond sharpening elements are used. Regardless of the material, their diameter varies in the range of 125 - 250 mm, the key points here are the size of the seats (most often this parameter is 32 mm), as well as the grit size of the abrasive. The latter is selected taking into account the state of the drill and the stage of its sharpening.

- Grinding belts and accessories, which are most often found on universal models of sharpening machines.

- A protective shield, which is a transparent shield in the form of a plate. The presence of this element is dictated by the requirements of safety regulations and is mandatory.

- Equipment start and stop buttons.

Experienced craftsmen advise, when choosing machines, to give preference to models equipped with asynchronous power plants. Their main competitive advantages include, first of all, maximum resistance to voltage drops in the network.

Among other things, it should be taken into account that sharpeners intended for use in everyday life, small workshops and small businesses, are characterized by a rigid attachment of abrasive elements. In this case, the movable part is a rig with a fixed drill.

In most universal modifications of the electric sharpener, the grinding wheel is fed to the processing object.

Species overview

Most of the described devices are automated equipment with a narrow specialization. In other words, such installations are only intended for turning drills. They are classified mainly taking into account the scope and the following two categories are distinguished.

- Industrial (professional), having increased power and intended for sharpening drills that are constantly used, therefore, often dull. We are talking about equipment designed for intensive operation at maximum loads in the conditions of enterprises and carrying out sharpening in a fully or semi-automatic mode.

- Household sharpenersthat can be used at home and small workshops. Their main distinguishing features are relatively low power, compactness and mobility.

Also, the described devices are divided into narrowly targeted and universal. The latter differ from their specialized "counterparts" by the presence of additional devices that allow sharpening not only drills.

In this case, we can talk about almost any tool that has cutting edges, including various saws and milling cutters.

Household

Of course, at home, ordinary emery can be successfully used to sharpen a small diameter drill. However, the use of modern models of specialized equipment will greatly simplify and speed up the process. It will also improve the quality of tool processing. In this case, we are talking about the following clear advantages:

- the ability to operate when connected to a conventional power supply;

- increased productivity;

- maximum simplicity of design and operation;

- increased sharpening accuracy;

- affordable cost;

- compact size and light weight;

- a convenient and intuitive control system for the apparatus, which provides, among other things, a smooth change in the rotation speed.

In the overwhelming majority of cases, household models of the devices under consideration are designed to work with spiral drills for metal and wood, made of high-speed steel. At the same time, a certain range of diameters is structurally incorporated in them. Besides, many machines are equipped with additional diamond wheels for processing carbide inserts. As a rule, household units are focused on drills with a taper angle from 90 to 140 degrees and creating a relief with a sharpening of the transverse cutting edge.

However, specific models for the following types of metal drills can also be found on sale:

- having a two-plane backing;

- left;

- three-toothed;

- with increased productivity.

In accordance with numerous reviews, models equipped with a universal chuck will be the best option for a household machine. Also, in this case, we are talking about units that are equipped with sets of cartridges.

The latter, as a rule, are attached to the body of the sharpener and are always at hand.

Industrial

As a rule, professional models belong to the category of universal sharpening machines. They differ from household counterparts in larger dimensions, as well as in power and stationary installation. Accordingly, such a power determines the corresponding energy consumption, as well as the noise level during operation. Taking into account all of the above, such equipment is most often placed in separate rooms, and when performing work, they use noise protection means. On the domestic market, industrial equipment is represented by model lines of both Russian and foreign brands.

Besides, on sale you can find products of companies representing the Middle Kingdom, produced under domestic brands. In the overwhelming majority of cases, models of grinders are offered for processing drills and cutters, the diameter of which is up to 30 millimeters or more. Most of the professional samples of the described equipment have a horizontal layout. Although vertical devices are found, they are much less common. The delivery set of industrial machines includes a set of collets designed for fixing the tool. In this case, the positioning accuracy is 10-20 microns.

Popular brands

On the one hand, the range of tools for sharpening drills presented in domestic stores can be called limited. This is largely due to the fact that even the simplest models can be quite expensive for many. But, despite this, the popularity of machine tools, both professional and household, continues to grow steadily. And the key point in this case is the good performance of the machines.

Taking into account the increasing demand on various specialized platforms, up-to-date ratings of the best and most popular brands and specific models are published... The list of those can include the following samples of equipment.

STURM BG6017S

STURM offers its potential customers the BG6017S model, equipped with a wheel with an outer diameter of 58.8 mm and designed for sharpening and dressing drills both for metal and wood. The stationary machine received from the developers a 70-watt motor, which allows it to effectively cope with its tasks in domestic conditions and in production. BG6017S is capable of processing drills with diameters ranging from 3 to 10 mm.

For sharpening, the tool is placed in a vertical channel equipped with a rotating abrasive wheel. The latter has a protective cover to prevent possible injury.

Instar STCH 60090

Another leader in the current ratings of the most demanded sharpening machines is STCH 60090 from Instar. This model is equally successfully used in locksmith and carpentry workshops, as well as at home. The device is intended for sharpening not only drills, including crown drills, but also cutters, blades and other tools with cutting edges, the diameter of which is 3-10 mm.

The maximum stability of the machine is provided by rubberized feet, and the optimal rotation speed and the corresponding intensity of sharpening of the equipment are provided by a 90-watt motor. Wherein the torque reaches 1500 rpm, and the weight of the device does not exceed two kilograms.

The equipment is characterized by maximum ease of use and does not require frequent and laborious maintenance.

PARKSIDE PSS 65-A1

The next representative of the conditional TOP is the PARKSIDE PSS 65-A1 universal machine. The main performance indicators of the entire model range include fast and high-quality sharpening of drilling and other tools, provided by a diamond wheel. The device is equipped with a whole set of fixtures for fixing cutters, knives, chisels, scissors and twist drills.

The PSS 65-A1 is equipped with a 65-watt motor and has a machining angle adjustment system with a range from 15 to 50 degrees. A spare diamond grinding wheel is included in the scope of delivery of the device.

"Diold" MZS-02

Quite deservedly, the leading positions in the ratings are occupied by products of the domestic brand "Diold". This can be proved by the example of the multifunctional model MZS-02, intended for household use and sharpening drills for metal, as well as knives, axes with a narrow blade and scissors. The machine is equipped with special branded abrasive elements.

The manufacturer recommends operating the equipment in a temperate climate at temperatures from -15 to +35 degrees. MZS-02 is connected to a household power supply with a voltage of 220V and a frequency of 50Hz.

Drill Doctor 500XI

The Drill Doctor 500XI is a striking representative of the sharpener family marketed by the Darex division of the United States of America. In this case, we are talking about professional, industrial equipment designed for processing tooling with a diameter of 2.5-13 mm and having an adjustable sharpening angle... The highest quality results are provided, among other things, due to the unique system of self-centering cruciform undercutting.

One of the key features of the machine is the maximum ease of changing the diamond wheel. It is also worth noting that a reliable chuck provides high-quality fixation of drills of the specified diameter.

In addition to everything already mentioned, it is worth paying attention to such characteristics of the 500XI model.

- A powerful enough electric motor that provides up to 15 thousand revolutions per minute.

- Power cord with a length of 1.83 m.

- Multifunctionality.

- Ability to sharpen HSS and cobalt-alloyed drills, carbide-tipped tooling and concrete drills. There are two sharpening angles - standard (118 degrees) and for hard materials (135 degrees).

It should be noted that at the moment there is a possibility of acquiring not only new models of domestic and foreign, but also Chinese manufacturing companies. In addition, there is a secondary market for the electrical equipment in question. Such specialized sites offer potential buyers working equipment with appropriate performance indicators at the most affordable price. And we are talking about household and professional tool sharpening machines.

How to choose?

When thinking about purchasing a machine of the described type, one should initially determine the scope of its application and evaluate the features of the operating conditions. For example, if it is planned to periodically use the device in everyday life, in the garage or in the country, then a low-power model belonging to the budget price range will be quite enough. It is important to take into account that industrial machines are designed to work with drills of large diameters, which are extremely rarely used at home.

One of the key selection criteria is the availability of a machine speed controller. This option maximizes operational efficiency while minimizing energy consumption and operating costs. An equally important point is the range of tool diameters with which the device can work. When choosing a household model, you should also focus on the noise level.

By the way, this parameter is also relevant for sharpening machines that will be used in garages and small workshop premises.

In addition to everything already listed, it is recommended to pay attention to the design features of the equipment models under consideration. Experienced experts advise you to opt for maximum simplicity. This approach will significantly reduce operating costs. In this case, it should be borne in mind that many foreign models to repair can be expensive.

Another important point is the correct choice of the equipment supplier. It means that you need to purchase machines only in specialized stores. And, of course, the financial side of the issue is included in the list of key criteria.

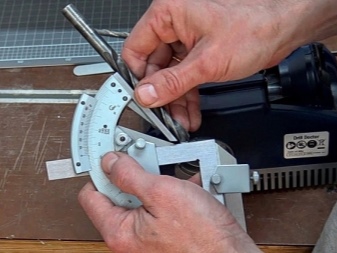

In the next video, you can take a look at a homemade drill sharpener.

The comment was sent successfully.