All About Drill Sharpening Accessories

A blunt drill inevitably degrades the working capabilities of the machine on which it is installed, and makes it almost impossible to adequately perform the task at hand. In the meantime, in the process of intensive work, the drills will inevitably become dull. Fortunately, most of them suggest the possibility of sharpening for further use, but for this you need to have the appropriate tool on hand. In fact, it is not even necessary to spend money on it - instead, such a device can be made with your own hands.

Peculiarities

Self-made drill sharpening devices appeared, probably long before industrial enterprises established their production. Self-made samples are, as a rule, primitive, but they cost their manufacturer a mere penny, and the problem can be solved no worse than a purchased analog.

For the hand-made manufacture of sharpeners, any available materials that meet the technical parameters are used. The simplest version of a sharpener is a sleeve, which is rigidly installed on the base at a convenient angle. The fundamental point for such a product is precisely the most reliable and durable fixation.

Experienced craftsmen note that the deviation of the fixed drill from the sleeve by at least one degree is fraught with a violation of the sharpening procedure, which means that it will negatively affect the efficiency of the drill.

If you have the necessary "parts" and skills, you can always improve the design of the product somewhat. For a more reliable fixation, you can always introduce bars with holes in a homemade machine tool, which are just the right diameter for the tips. Sometimes several small tubes of aluminum or copper are used instead.

Regardless of which design option you choose for self-production, it should be remembered that sharpening any tool, including drills, requires certain specific skills. which are acquired only with experience. The following abilities are most often implied:

- good eye - to correctly determine the angle of sharpening and a sufficient distance for the gap between the processed tip and the abrasive surface;

- understanding the principles of operation of electrical devices - in order to correctly assess the ability of the engine used to sharpen certain drills;

- orientation in the specifics of metalworking - allows you to understand how to sharpen the drill correctly, what its sharpening angle should be, and also contributes to the timely identification of the need to restore the sharpness of the tip.

It is possible that the first self-made copy of the tip sharpening device will turn out to be imperfect and will require additional adjustment or adjustment, however, it is important not to be afraid of disappointing results, but to try, and over time everything will work out.

Species overview

Regardless of what type of fixture you will make with your own hands, please note that ideally it should be mechanical, because otherwise it will be long and difficult to sharpen each individual drill. As for the existing varieties of similar products, it must be admitted that objectively, the number of their options is not limited by anything, and there is no complete classification and cannot be, because human engineering thought is limitless.

For this reason, we will highlight only a few examples of machines and simpler equipment, which are often reproduced in everyday life.

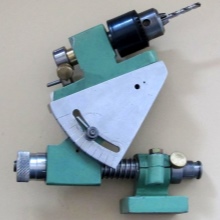

- Drill bit. Predictably, one of the most common options, because a drill is in the arsenal of almost any master, and it already provides a mechanical drive, and it is very easy to make a nozzle on it. The product is a nozzle made of a metal pipe, in the upper part of which a conductor is screwed - holes of just such a diameter are made in it so that the drill goes in and fits securely in its place. Before sharpening, the structure is attached to the drill neck using a bushing and a screw.

- Sharpening stands. Some of these structures are widely used in production, but there they are more cumbersome and have advanced functionality, while at home they are assembled in more compact and less advanced versions. The stand is in any case inseparable from the sharpening machine, so it should be assembled if you have the machine. The tasks of the craftsman include the independent production of a base, a rod and an emphasis from improvised means. Drills are attached to the rod with specially selected clamping nuts of the required size, but you need to make sure that they are tightly fixed.

- Clips of various types. In fact, in most cases, craftsmen do not complicate the task and sharpen the drills by any means at hand - with the help of a diamond grinder disc or even on emery. In this case, the entire sharpening device is a holder in the form of a mandrel into which the drill is inserted. It is not difficult to make such a product, but it is important to achieve perfectly accurate fixation in the correct position of both the drill itself and the retainer, which may well be assembled from just two small nuts and a bolt.

How to do it yourself?

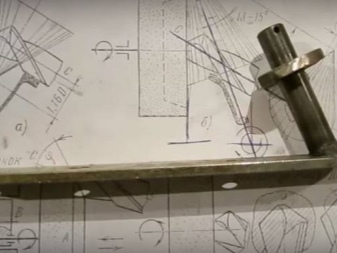

The decision to make any mechanism with your own hands always begins with the creation of a drawing. This rule works always and in all cases, even if it seems to you that the device planned for production is very simple. It should be borne in mind that a drawing is not just a conditional diagram; it must necessarily contain the dimensions of all individual parts, as well as the entire mechanism.

Do not be too lazy to enter information even about the sizes of fasteners, and then recheck several times in a row if everything converges.

If this is your first experience in making such devices on your own, there is nothing surprising in the fact that problems begin to appear already at the stage of drawing up a drawing. It's okay - you just have to make the mechanism with your own hands, and not develop your own working project. As such, it is not forbidden to use the Internet to borrow a drawing from someone. At the same time, it is worth remembering that not all authors on the network understand what they are writing about, which means that the drawing should not be taken into work, blindly trusting the source - it should also be double-checked for compatibility of all parameters in relation to each other.

It is also advisable to make sure that you already understand how the final result should look and work before starting execution.

Made of metal

For solving problems of sharpening small drills, a device assembled "on the knee" from ordinary nuts is excellent. On the Internet, you can find insignificantly different recommendations regarding the step-by-step manufacture of such a device, but most often everything looks like this.

First you need to find two nuts, the diameter of which would not be the same. On a larger one, you need to make a markup, measuring 9 mm on one of the edges on three sides. The measurement results are indicated by a marker on the selected face, as well as on the one that is opposite to the first.After the marking is completed, the nut is clamped in a vice and small fragments are cut off along the drawn contour.

After that, a drill is inserted into the cut nut to make sure that the edges of the nut provide the drill with the same 120 degrees of inclination, which are usually considered the most successful position for sharpening and subsequent work. If everything matches, you can proceed to the next stage - a nut of a smaller diameter is applied to the surface that has been cut off and, making sure that the position is correct, welded it. Then a bolt is screwed into the smaller nut, which limits the movement of the inserted drill - as a result, a holder is obtained that provides the required angle.

Experienced craftsmen emphasize that it is the bolt that should provide fixation, and you should not try to replace it with your hand or other less reliable devices.

Due to the specifics of the described design, you can insert the drill into it at the correct angle and fix it in this position. After that, the drill is ground on emery in the expectation that the nut device will not allow to grind off the excess, at the same time grind off itself. At the same time, many craftsmen doubt whether the nut is really capable of withstanding the processing effect of the abrasive wheel and not deteriorating, at the same time spoiling the drill, which is sharpened at the wrong angle.

There can be only two options for solving this problem: either choose any other tools for sharpening drills, or carefully choose the nuts from which you will make the clamp.

Made of wood

Do not think that you can make a drill sharpener with your own hands only from metal - in fact, wood is also suitable for achieving such goals. At first glance, it does not provide the same reliability of fixing in the correct position, however, practice shows that even in a wooden version, the retainer is able to serve its owner flawlessly for some time.

At the same time, even a person who has absolutely no welder skills or does not have welding as a unit can make it, but a still not blunt drill will be required for production.

A piece of wood is used as the main material, the thickness of which is optimally estimated at 2 centimeters. Diagonal markings are performed on the end side of the future product, trying to determine the center. After that, you need to make a through hole with a suitable drill at the middle point - in diameter it will be just such that in the future it will fix the tool with which it was made.

Next, you need to cut the corners so that the cut lines go 30 degrees along the protractor, if we recognize the center as the reference point. Then another hole is drilled from the side or from above, intended for the fixing self-tapping screw. Its hole in the thickness of the bar should be connected to the slot for inserting the sharpened drill - then, using the fixing bolt, the drill can be reliably pressed.

The principle of using such a device is quite simple - the drill is inserted into the hole made for it, and then fixed, tightly pressed with a bolt. In this case, the tip of the drill intended for sharpening should protrude beyond the wooden frame. Experts advise using a similar design to work with a grinder or belt grinder. It is clear that the wooden case will also succumb to the sharpening effect and wear out, therefore the task of the grinder is to ensure that this does not happen too pronounced.

Wooden drill sharpeners are not made for drills of exactly the same diameter - they are universal and can be used for sharpening products of different diameters. Moreover, it should not differ significantly from the maximum possible.If the diameter of the hole for the drill is 9 mm, then here you can sharpen nozzles with a thickness of 8 or even 7 mm, but 6 mm is already undesirable. With a wider assortment of drills in the master's arsenal, for sharpening thinner tips, it is necessary to make another such structure with a diameter of 6 mm, where it will also be possible to sharpen products with a thickness of 5 and even 4 mm.

How to use a homemade device?

The principles of using homemade drill sharpeners are highly dependent on what kind of device was produced. If you do not go into the specifics of each individual device, but try to give general recommendations, then the instruction will turn out to be relatively short - we will consider it.

If sharpening is carried out on emery or a fixed grinder, that is, these devices already have a clearly defined position in space and cannot independently move relative to the table, the task of the master is to similarly fix the self-made adapters. It is most convenient to fix the mechanism with the help of clamps, but you need to carefully monitor the distance at which the fasteners are installed from the abrasive - your task is to ensure that they are located close enough to each other, allowing you to sharpen.

When the correct position is found and you are ready to test your own design, loosen the clamp to allow the drill to slide into place. Now place the drill in the hole intended for it and look for a position in which the sharpening angle is ideal, and the surface of the drill is firmly pressed against the surface of the stone. Do not settle for "intermediate" solutions - if your structure is manufactured and assembled correctly, you will be able to find the ideal position by adjusting the clamping yoke, if you made a mistake somewhere in the calculations, then it makes no sense to sharpen something on an unsuitable machine.

When the optimal position for the drill in relation to the sharpening part is also found, securely fix the drill with the help of those fasteners that are provided in the homemade device specifically for such purposes. Leave a small gap, which is usually estimated at 1 millimeter - your task is not to break the tip, you only need to grind it a little. Then start an abrasive disc or other grinding device and test your own machine in action.

After enough time has passed for adequate sharpening, stop the process and evaluate how well your own sharpener is working.

If everything is in order with the drill, and it is sharpened exactly as it is necessary for your working needs, a similar procedure must be repeated from the reverse side, because until this moment the drill was grinded only along one of the edges. The tip is turned 180 degrees by loosening and then retightening the fasteners, however, in this case, you do not need to touch the restraining bolt at all - it must provide the same length of sharpening as when machining the reverse side.

After that, you can sharpen your own drills at any time, as soon as the need arises. If you work mainly with soft materials with a relatively low density, such a need will arise relatively rarely, but metalworking always creates a huge load on the drills and requires regular use of sharpening devices.

There are several ways that have been tried and tested over the centuries to know when a drill is already in need of a sharp edge update. First of all, after prolonged use, the edge of a metal drill begins to get tired, which is why the tip can literally begin to crumble.This phenomenon often frightens beginners and forces them to completely replace the drill or completely abandon the processing of a certain material, but in reality it was just necessary to restore the correct working shape of the nozzle.

Besides, with a blunt drill, the motor begins to experience overload and excessive heat - this is understandable, because to achieve this goal with a substandard handpiece, the motor has to work harder. Finally, a dull drill always leaves characteristic ragged burrs on the work surface - this is because the dullness is not uniform on all sides of the drill, and it gradually spoils the tip.

For information on how to make a device for sharpening drills with your own hands, see the next video.

The comment was sent successfully.