Features of small drills

The features of small drills are a must for every novice home craftsman. It is necessary to find out what the diameter of the drill for a mini drill can be, and what the smallest drill can be. You should also understand the peculiarities of their use.

Description and purpose

Small drills, as you might guess, are devices for drilling small holes. They are usually purchased for a mini drill. Such a device is very helpful in a number of everyday tasks, and is especially valuable in the practice of radio amateurs and modelers. It significantly saves time compared to drilling small holes with an awl and other improvised means. The risk of breaking a part is also greatly reduced.

Miniature instruments also work much cleaner than improvised gadgets. After them, smooth cylindrical or other grooves remain. But it is important to understand that a good mini-drill, like auxiliary tools for it, cannot be cheap.

There are different types of them, and now it's time to talk about exactly this.

Species overview

First of all, it is worth highlighting the point that all drills, regardless of the diameter, are divided into two main groups. One works with wood and other soft materials, and the other with metal. Structures for metal processing have a pair of longitudinal grooves that divert chips to the side. Core drills are not found in the smallest group - they are needed to make powerful holes. Tapered models cope much better with the passage of a channel of various cross-sections: you only need to outline the section of the circle and accurately determine the center of drilling.

Simple twist drills with a single chip clearance slot are needed for woodworking. They are sold in a wide range - and the smallest is only 3 mm. True, one must understand that a deep hole cannot be made. This is contrary to the laws of physics, and a very thin elongated drill will always break. And if you need to make a perfectly flat blind hole, Forstner's drill is an excellent choice; fixtures up to 3 mm in cross-section may not be marked at all, and this is normal.

As for the Forstner drills just mentioned, their cutting part pierces the fibers around the perimeter faster than the main blades go into the tree. As a result, the appearance of chips is almost excluded. Such a moment is extremely important when the goal is to make a neat cut. The Forstner drill maintains an accurate course due to the rim (other structures do this thanks to the central rod), and this is very valuable when it is difficult to maintain the direction of movement in the material.

It is worth noting that Forstner's drill is unique. Unlike fakes, its cutting edge is only interrupted at 2 points by the main blades. And the blades themselves are sharpened by hand. The only official manufacturer of such products is Connecticut Valley Manufacturing. These drills are not cast, but milled from carbon steels, and the result is almost complete protection against overheating.

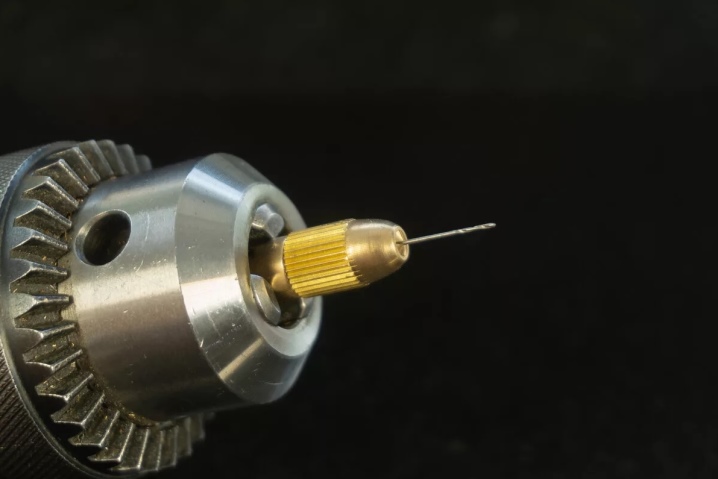

The smallest - less than 1 mm - drills are designed for work at high speeds. Simple screwdrivers with an auto-centering chuck will not help here. Micro drills from 0.1 to 1 mm usually have a round cross section. A typical woodworking kit contains up to 10 pieces of 3-12mm fixtures. Fine work kits can include tools from 0.03 to 0.32 cm.

For the manufacture of drills can be used:

-

HSS-E steel with 5% cobalt;

-

HSS-G - for softer materials;

-

high-speed steels of the HSS-R class.

How to use?

Drilling with small drills is complicated by the more intense influence of interfering factors:

-

the beat of the drill itself;

-

spindle runout;

-

dependence on surface quality;

-

the intensity of the tool departure;

-

uniformity of tool feed.

Before starting work, the drills must be properly secured in collets or chucks. The standard runout of the spindle is strictly limited. The deviation of its axis from a strict perpendicular in relation to the table does not exceed 0.0005 cm. The greatest allowable runout of the cutting edges is 0.0015 cm. Visual control of the correct fastening is carried out using a magnifying glass, increasing by 4-10 times.

Through it, the spindle rotating at a speed below 1500 rpm twists the drill so that it resembles a monolithic rod. Chip grooves should not be visible. More professional use of the device based on:

-

plates;

-

microscope MBS-2;

-

bracket.

The comment was sent successfully.