Review of Artu drills

A drill is usually called a cutting tool, which is designed to make holes in different materials. For each specific object, there are special types of drills that differ from each other in the design of the working and tail parts. The drill must be inserted into a drill or hammer drill - these devices will give it the required rotational force. Currently, they are electrically driven and easy to operate.

Peculiarities

The German company Artu was founded in 1979. She quickly gained popularity among customers, producing high quality and impact resistant tools. This brand creates durable universal drills for metal, glass, concrete, hard ceramics. The products are manufactured using tungsten carbide, which surpasses technical diamond in its properties. The top of the instruments is nickel-chromium-molybdenum plated.

Artu drills operate at high speeds - about 3000-3200 per minute. They can be used for hammer drilling. The tools have a negative angle of sharpening of the cutting edge, due to this, the initial moment of work is stabilized. The total service life is about 5000 holes in concrete.

In addition, Artu brand products are provided with clear and detailed instructions.

Assortment overview

Artu drills are sold both singly and in special sets. Several options are most popular.

- A set of crown drills in a cardboard box No. 3 (33, 53, 67, 83). This option is a combination of excellent quality and low price. The set is ideal for work requiring core drills with different diameters. They are treated with tungsten and carbon tungsten carbide chips to prevent shattering and extend service life. This set is indispensable for construction and installation work with cables, pipes, when installing sockets.

The kit includes several items.

- Core drills with diameters of 33, 53, 67 and 83 mm.

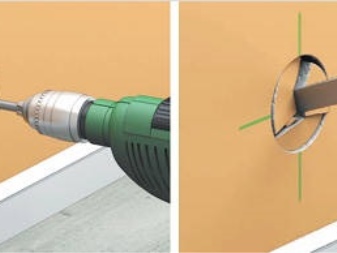

- Carbide center drill with a diameter of 9 mm. It is necessary for the accurate operation of the crown tool in order to obtain an even hole.

- A landing flange, which is used in order to install core drills of any of the available diameters on it, as well as a centering one.

- Core drill with a diameter of 67 mm. Using such a tool, you can make large-diameter holes in ceramics, tiles, foam concrete, brickwork, drywall, marble, cement slabs. It is based on a hard alloy of tungsten carbides, silicon, titanium. Thanks to this, the tool becomes highly durable and wear-resistant. Used for installing outlets, laying pipes, pipelines, drain lines.

The crown model is installed on a drill using a mounting flange and a center drill. The tool is 13 mm long and 11 mm wide. The product weighs 173 g.

- Twist drill set CV PL (15 pieces, in metal). Consists of impact-resistant attachments that can defeat even reinforced concrete and granite. Due to the fact that the working plate is fixed using high-tech soldering at temperatures above 1300 degrees Celsius, the tool works with strong heating (up to 1100 degrees) without losing its working qualities. The set includes 15 drills of different diameters: 3; 3.5; 4; 4.5; 5; 5.5; 6; 6.5; 7; 7.5; eight; 8.5; nine; 9.5; 10 mm. The weight of the packed product is 679 g.

Secrets of selection and operation

In order to choose a quality drill and use it correctly, you need to carefully read the recommendations of specialists:

- universal drill Artu can be used when working with materials of different hardness;

- when working with concrete, it should be borne in mind that the first dressing of the cutting edge is carried out after 60 drilled holes along the entire length of the tool;

- drills with yellow titanium coating, unlike black, can withstand temperatures 200 degrees higher;

- for drilling concrete, it is necessary to use the perforation mode and low speed - 700-800 rpm;

- if there is reinforcement in the concrete material, you should switch the drill from perforation mode to drilling mode, and then return to the previous one;

- Sharp sharpening angle of the tool indicates that it is intended for working with soft metals, and for very hard metals, the angle is 130-140 degrees.

See the following video for an overview and test of the Artu drill.

The comment was sent successfully.