How to check the pump of a washing machine?

Automatic washing machine is one of the most popular classes of household appliances. However, like any complex unit, a washing machine needs care and sometimes repair. To avoid costly replacement of assemblies and parts, it is necessary to correctly diagnose the problem. This article will focus on checking the drain pump.

When should you diagnose?

The need to check the serviceability of the drain pump arises when a number of symptoms appear. For example, the washing machine stops draining water from the tank when switching to another mode of operation, or this process is slow, which can lead to a program failure. Sometimes it is necessary to check the pump of the washing machine when a signal of a certain malfunction appears on the display. All these signs do not always mean that the pump has broken down and must certainly be replaced. Quite often, the performance of the unit can be restored as a result of elementary cleaning.

It is to identify the severity of the problem that diagnostics is aimed at.

Preparation for work

If any malfunctions in the drainage system appear, it makes no sense to wait for improvements, it is necessary to diagnose the problem as soon as possible. Unfortunately, it itself will not disappear, and it is not worth aggravating it by waiting, if only because it will provoke more serious problems, the elimination of which may require corresponding capital investments. Checking the condition of the pump will require dismantling it, and this cannot be done without the appropriate tools.

Manufacturers do not have the same arrangement of pumps in their washing machines.

So, if for some this unit is located behind the tank, it is easier to get it - you just need to remove the back panel. Others will have to remove a number of components that have nothing to do with the pump, including the control panel. Thus, even before removing the pump, you need to familiarize yourself with the structure of your washing machine and assess your capabilities. Sometimes it is better to refuse an independent check, if only because there is no necessary set of tools at home to carry out the entire operation. Getting all the inventory you need may not be all that cheap. If, nevertheless, a decision is made on an independent inspection and possible replacement of the pump, first of all, the toolkit should be prepared:

- flat and cross screwdrivers;

- a screwdriver with replaceable tips;

- pliers;

- hammer.

To study the resistance of the pump motor winding, you will need a multimeter. Sometimes it is the need to purchase this testing device that stops further preparation for diagnosing the washing machine pump.

However, you should not be afraid of this at all, the device pays off rather quickly, eliminating unnecessary repair costs and other household appliances.

How to get to the drift?

It is not difficult to see the pump in most models of modern automatic washing machines. Many are familiar with the procedure for cleaning the drain filter, removing it, you can see and even touch the pump impeller. Often it is the clogging of the filter and impeller that becomes the first reason for the pump to stop. But getting to the node itself is not at all so easy. Moreover, for different models, its location may not be the same. In this case, the universal actions are as follows.

- Disconnecting the washing machine from the power supply.

- Disconnection of the supply and discharge pipelines.

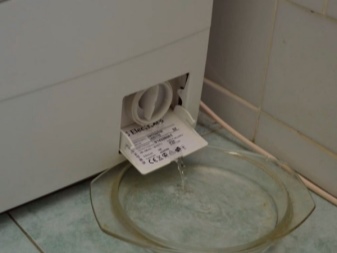

- Draining residual water from the tank.

- Removing the detergent drawer.

- Moving the washing machine to a free space and placing it on the side, on the right side.

If the washing machine does not have a removable bottom, access to the pump can be considered open. Otherwise, it is necessary to remove the removable bottom panel, on which a leakage sensor can be installed, the task of which is to stop the washing machine when water gets on the contacts. If the bottom is exactly like this, you must first disconnect the sensor terminals so as not to damage the wiring.

Some manufacturers install the pump at the back of the washing machine - this is the most convenient position for manipulation. The pump can be seen by removing the back panel. This is often enough to get free access to this node. Sometimes the machine still needs to be laid on its side. The front position of the drain pump is the least convenient for dismantling. In this case, the above action plan is not enough. The front panel of the washing machine must be removed. And this will require a number of preliminary operations.

- Remove the top panel.

- Remove the detergent drawer.

- Remove the control panel.

- Remove the loading door cover.

- Remove the collar from the hatch body and put it inside the drum.

- Disconnect the hatch lock wires.

- Remove the front panel, and for some models, before that, also remove the decorative plastic cover, without which it is impossible to get to the screws securing the front panel.

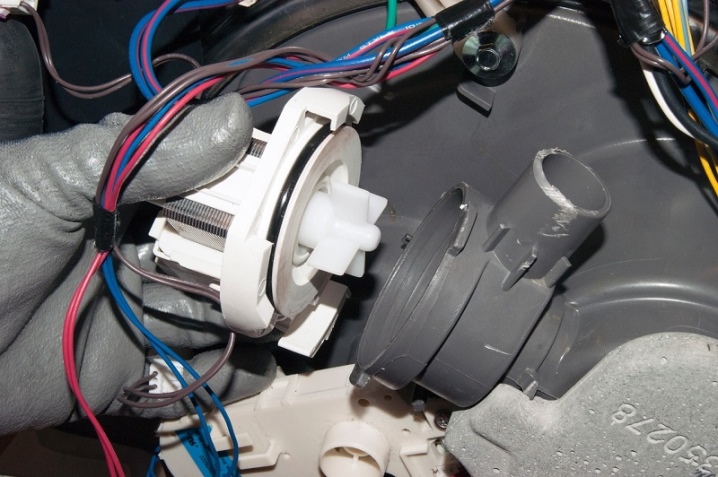

And only then will access to the drain pump located below to the right of the tank open. It is this position of the drain system in Bosch and Siemens washing machines that allowed these manufacturers to reduce the dimensions of their models as much as possible. Having gained access to the node, it is no longer difficult to dismantle it. Most often it is fastened with bolts. It is also necessary to disconnect the inlet and outlet pipes. To do this, remove the steel clamps using pliers.

Taking this opportunity, it is advisable to clean the pipes of dirt, their clogging can also cause malfunctions of the washing machine drain system.

How is the check done?

When the pump is removed, first of all, it is necessary to visually assess its condition. A problem may be caused by pieces of fabric, thread, or hair wrapped around the impeller or shaft. Simple mechanical cleaning can solve this problem. However, there is no way to end the check at all, it makes sense to ring the pump with a multimeter. Having connected the contacts to the terminals, it is necessary to measure the resistance with a tester, and if the arrow of the device froze in place or deviated within one unit, the motor burned out - the pump will have to be replaced.

You can find out about typical malfunctions of drain pumps in washing machines below.

The comment was sent successfully.