Why is the drum knocking in the washing machine and how to fix it?

A washing machine is one of the most necessary and important household appliances in a house or apartment. But nothing lasts forever, and over time they begin to "be capricious" and cause inconvenience to their owners. The most common problem is the appearance of extraneous noise during washing or during spinning. Why this happened and how to quickly fix it, we will find out in this article.

Causes

If the drum started to knock in the washing machine, it means that something went wrong - you need to find out the cause of the extraneous noise during washing. For automatic units, everything is arranged approximately the same, that is, all the main noise factors during washing or spinning can be determined and classified for all brands of such household appliances.

- The most common - the presence of various foreign small objects inside the drum... When loading things into the machine, it is imperative to remove everything that is there from the pockets. When the washing process is in progress and the revolutions are small, metal objects fall down, but during the spin cycle, when the rotation speed increases, these things can get stuck between the tub and the walls of the washing machine. An unpleasant metallic sound will be heard. The presence of coins and other small things inside the drum during the washing process can damage the home assistant.

- Bearing depreciation. A necessary and important element for the correct operation of the machine is the bearings; the stability of the drum rotation depends on their reliability and wear. If the machine hums a lot during spinning, this may indicate that the bearing life is coming to an end. The first sign of the beginning of bearing amortization is an unpleasant rattling sound when the drum rotates. If you do not take action, then it will begin to hum and thunder even more and eventually break. Determining the degree of wear without disassembling the machine is quite difficult. On average, bearings last about ten years and rarely fail.

- Bolts securing the drum during transport. A fairly common cause of extraneous noise is the forgetfulness of the owners. They forget to unscrew the bolts that protect the drum from unnecessary and unnecessary vibrations during transportation. If this is not done in time, then this can also cause extraneous noise.

- Dampers are broken. During the washing process, ratchet-like clicks are heard.

- Axis misalignment. One of the reasons the drum can wobble is a loose or even defect in the pivot axis.

- Counterweight. The drum is lightweight and additional weight is used to compensate for vibration. Sometimes its fastenings are loosened, and then there is a rumble and vibration.

- Breakdown of the water drain pump. In this case, the unit also spins noisily, beats during spinning.

- And probably the most common mistake is incorrect installation. If the washing machine is not level even horizontally, it will jump or make strange sounds during washing.

Diagnostics

To fix a breakdown, it must first be identified. Correct diagnosis is half of a successful repair. Before contacting the service center, you can identify some of the faults yourself.

- If a knocking is heard when the drum rotates, then most likely it is a change from the pocket or the clothes were not turned out so that the buttons and zippers were turned inward.

- If a strong squeak is heard when the machine picks up speed, it is likely that the bearing is worn out. To test this version, you need to open the door of the washing machine, press on the inner edges of the drum and scroll. Some skipping and cracking may be felt. It is likely that the bearing is defective.

- A knock on the body is sometimes heard during operation. Possible cause - imbalance of the axis of rotation. To exclude or confirm this breakdown, you need to check the drum play: if it is too large, then this is the problem.

- If the machine starts to make a lot of noise and vibration, then the counterweight mountings may have become loose.

- When you open the door, you can see that the tank has tilted slightly. When you press it, it hits the walls or other parts of the machine.

- If the washing machine buzzes very strongly while draining the water and stops working, then, most likely, the pump has broken.

- To identify the incorrect installation of the machine, you just need to click on one of its corners - it should not wobble. You can also check the building level.

Other breakdowns are more difficult to diagnose on your own, so if something knocks in your machine, then it is better to contact the master.

How to fix the problem

After identifying faults, some of them can be eliminated by hand, and for more complex ones, you will need to disassemble the machine. How to fix the most common breakdowns?

If foreign objects get inside the machine, you will most likely have to disassemble it. To do this, you need to open the lid, remove the electric heating element and pull these things out of the tank. In the event that it is impossible to reach foreign objects, you will have to completely remove the tank.

Replacing bearings is an inexpensive but difficult repair. If not replaced, they can break the crosspiece. To replace the bearings, the machine is completely disassembled, the tank is taken out. The bearings are removed from the attachment points and replaced with new ones.

When repairing, it will be correct to replace all elastic parts. Don't forget to buy a repair kit before starting repairs.

The shipping bolts must be removed before installing the machine in place - this will eliminate one of the causes of noise during operation.

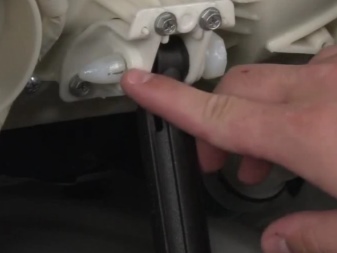

Shock absorbers are not repaired, but replaced. To replace the dampers, it is necessary to remove the rear cover of the machine, unscrew the fasteners located below the shock absorber tank, remove them and install new ones. Then carry out all the actions in the reverse order.

If the balance of the axle is disturbed, then it is necessary to tighten the nut on the pulley. In case of problems with the counterweight, remove the back or front panel (depending on the design of the device) and tighten any loose fasteners. If one of the weights has collapsed, and such cases are very rare, you need to replace it with a new one.

It is very easy to align the clipper. To do this, it must be installed on a flat floor, and by rotating the legs with a special key, we make it so that it does not swing.

Before proceeding with the repair, check if you have the necessary set of tools, repair kits and spare parts. And do not forget to disconnect the repair facility from the power supply and water communications.

Prophylaxis

In order for the machine to serve as long as possible, small precautions should be taken:

- things with small details that can come off during the washing process are best washed in a special bag;

- before placing items in the tank, check their pockets for debris, small items and other items that can damage the drum;

- do not exceed the loading of the washing tank, observe the restrictions;

- add special substances that soften the water - they will help preserve the heating element and remove scale;

- the machine must be level and secure;

- it is advisable to ventilate the internal elements of the appliance, for which you need to open the hatch for loading linen and the tray for detergents.

All these simple tips will help to prolong the operation of the washing machine and protect you from contacting a master or a repair and maintenance center, and, consequently, from unnecessary expenses.

For the reasons and repair of a washing machine that knocks, see below.

The comment was sent successfully.