How does a washing machine work?

An automatic washing machine can be found in almost every home, since this type of equipment is considered the most popular and irreplaceable item in life. Despite the fact that this household device can reliably serve for a long time, sooner or later troubles happen to it - one or another part fails. Most of the breakdowns in washing machines are not serious, and they can be easily eliminated with your own hands, but for this you need to know how the household unit works and what is the principle of its operation.

Types of washing machines and their differences

There are two main types of washing machines on the market today: automatic and semi-automatic. The first option is distinguished by its modern design, versatility and software control. Simple models are intended only for washing in certain modes, and more complex ones are able to independently set the temperature of the water, select the required volume of it, a portion of powder and spin speed. In automatic machines, the drum is the main working element; it is characterized by increased sensitivity to damage. The advantages of machines include significant savings in powder, water and electricity, they differ in volume (from 3.5 to 7 kg) and, according to the loading method, are divided into vertical and frontal.

Top-loading washing machines have a complex design, therefore, they are much more expensive than front-loading ones. During their operation, the drum flaps often open, which, in turn, can lead to malfunctions and subsequent repairs. A similar problem most often happens with budget models made in China.

The main advantage of vertical washing machines is that they have the ability to load additional laundry (without making changes to the program).

As for the units with a frontal type of loading, their purchase is cheaper than models with a top loading. This technique is characterized by unpretentious operation and rarely requires repair... A transparent hatch, located in the front of the structure, allows you to conveniently observe the washing process. It is produced with a sealing lip, which ensures a good tightness of the structure. The drum in such washers is fixed on one axis (for vertical models - on two), they are ideal for small apartments, since the upper body of the structure, if desired, can be used as a bedside table.

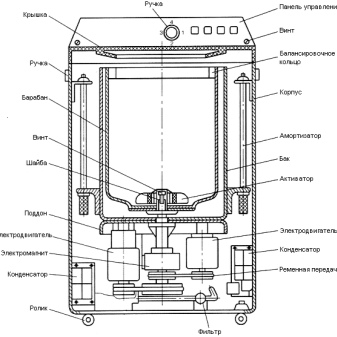

Semi-automatic washing machines do not have control modules, they are usually equipped with only a timer. Compared to automatic machines, in such models, the activator acts as a working element, which is a special vertical container with an electric drive. In addition, the design of such models includes a disc, which is responsible for mixing the laundry in the container. The main advantage of semiautomatic devices is their low weight, which allows you to transfer equipment to any place, no need to connect to a water supply system and an affordable price.

Please note that each model has a different load volume of laundry - from 1.5 to 7 kg. Cons - there is no water heating function and work programs.

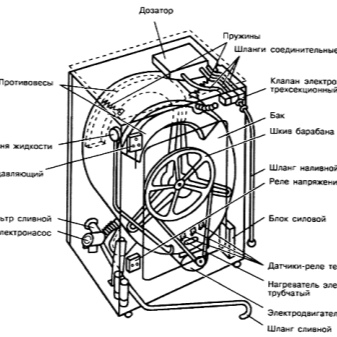

The main components and their principle of operation

Absolutely all automatic washing machines, regardless of model and brand, have an identical internal structure. In order to choose a quality unit at the time of purchase, you need to know its structure. Any washing machine inside consists of an engine, drain and filling systems, a control module, a rotating element (drum), a tank, a heating element and all kinds of sensors. To make it easier to understand how the automatic machine actually works, and to avoid difficulties with installation, you need to visually represent its section. Performing the repair of such household appliances at home, you will additionally need an electrical schematic diagram.

Tank

This element can be executed both high quality stainless steel and durable plastic. There is a perforated drum inside the tank, when it rotates, thanks to special ribs, the effect on the laundry is enhanced, and it is evenly distributed before the spin mode. Tanks are divided into non-collapsible and collapsible. There are also bolted versions.

Drum

This is one of the main components of the washing machine, which has view of a huge cylinder with numerous holes, made of high quality stainless steel. The front part of the drum is fixed to the tank by means of a rubber cuff, and on the back there is a crosspiece, to which the shaft is directly attached. The elements connecting the drum and shaft are seals and bearings.

Frontal counterweight

These are weights made of concrete or plastic, which are placed at the bottom of the rear of the case. In the course of long-term use, the front counterweight may crack or break. That's why the weight of the loaded laundry must be constantly monitored.

Engine

This element drives (makes to rotate) the drum. Usually, models the machine is equipped with a collector motor, fixing it directly to the drum itself. In addition, direct drive asynchronous and inverter motors can be found in many models.

They differ in power, power consumption and noise level during operation.

Drive belt

This part is necessary to transmit torque from the electric motor to the drum. Usually drive belts are made of rubber, sometimes there are also products made of polyurethane, durable neoprene or nylon. They are divided into several types: for units of domestic and foreign production and for large-, small-sized machines.

Pulley

A drum pulley is a small wheel mounted on a shaft. With the help of this element, movement is transmitted to the belt. The maximum number of revolutions in the spin mode largely depends on the diameter of the pulley. This part is cast from aluminum. The pulley is attached to the drum shaft by means of a splined connection.

Shock absorber

Since the machine can generate vibration while rotating at high speed, the tank is suspended from special springs. Such shock absorbers are fixed to the side wall and look like a piston that enters the cylinder.

The service life of not only the bearings, but also the belt drive directly depends on the quality of the shock absorbers.

Heating element

This is a heating element installed at the bottom of the tank, it can be controlled using a special temperature sensor. Often, due to the use of low-quality water in the water supply, the heating element is covered with scale. To extend the operating life of the heating element, many manufacturers cover it with a ceramic layer that protects it from plaque or corrosion.

Pressostat

To control the water level, a special relay (pressure switch) is installed in each unit, which looks like a cylindrical box with contacts for switching and terminals... A pressure tube and electrical wires are separately connected to the pressure switch, the level starts to work when the indicator of the water column is 500 mm.As soon as the water column has reached the required height, the pressure is transmitted to the level sensor, and the electronic module of the unit begins to respond to this, immediately starting the next cycle of operation.

Filling valve

Each model of washing machine uses a specific valve, which can be either one, two or three sections. As soon as voltage is applied to the coil from the control unit, an electromagnetic field is triggered, and the valve instantly begins to open. Then the jet is delivered according to the previously set program into each compartment of the dispenser.

Dispenser hopper

It is a compact box, several separate branch pipes can be connected to it. The upper part of the hopper has many holes, through which water penetrates, which washes away the washing powder. Besides, the dispenser has from 1 to 5 compartments, each of which is indicated by its own specific symbol.

Drain pump

Any wash ends with a waste water drain, which requires a drain pump. This element is located on the front of the housing and is equipped with a filter. The drain pump is usually equipped with an inexpensive rotary motor. In modern models of washing machines, you can also find a circulation motor.

Any small debris (in the form of coins and buttons) can easily cause such a pump to malfunction. To avoid this, the filter should be cleaned regularly.

Other parts

In addition to the above details, the design of any automatic machine also includes a control panel, an electronic module, which are responsible for starting all operating modes in the unit. This is the so-called brain of the equipment, which looks like a board. All washing processes are controlled by special commands. User feedback with the electronic unit occurs through the control panel in the form of light indicators on the displays.

An important element is the hatch cuffs - this is a rubber seal, which ensures the complete tightness of the unit. Its inner part is fixed with a clamp to the tank, and the outer part is fixed to the vehicle body itself. The cuffs can be located between the front wall and the tub (for front-loading models) and between the tub and the top panel (for washing machines with a vertical loading method).

Washing process

All automatic machines, regardless of technical characteristics, work according to the same principle: first, power is supplied to the control panel according to the selected program, then the panel gives the appropriate commands, collecting all information from the sensors. Then the following happens:

- the door is locked, and water is drawn into the powder container and into the tank;

- then the temperature is adjusted and the water is heated using the heating element;

- at the optimum temperature, the washing mode starts, and the motor starts to work, it sets the drum itself in motion.

In practice, in order to use an automatic washing machine, you need to follow these steps:

- the first step is to turn on the unit and fill the drum with linen, then washing powder is poured into the tray and the desired operating mode is selected, the appliance door closes;

- powder from the cells is washed out by streams of water and sent directly to the drum, whose movements contribute to the uniform distribution and getting wet of the laundry;

- then the waste water is drained and rinsed (it is worth noting that it happens more than once), which is accompanied by the release of water into the drain and the injection of clean water from the water supply;

- the final stage in washing is spinning the laundry when the drum is at high speed, making 1200 or more revolutions per minute, starts rotation.

After that, the liquid leaves through the openings of the tank, it collects at the bottom of the machine and from there is pumped out with sediment, falling into the drain hose and discharging directly into the sewer. The dryness of the laundry is largely dependent on the speed of revolutions in a particular model of automatic machine. It should be noted that for each washing mode, the spin speed is different. For example, for a delicate wash, it does not exceed 800 revolutions in 60 seconds. At the end of the work, the unit turns off on its own, the user only needs to disconnect it from the power supply.

An important point after washing is that the door of the machine will remain locked for a certain time, and you should not try to open it forcibly. As soon as the hatch opens on its own, you can take out the washed laundry and dry it. After washing, leave the machine open for airing. If you follow all the basic rules for using the washing machine, do not overload it with linen, provide it with clean water and constant power supply, it will last a long time and will not disappoint its users with frequent breakdowns.

In the next video, you will find the principle of the washing machine.

The comment was sent successfully.