Do-it-yourself Indesit washing machine repair

Among the large assortment of washing machines, Indesit is not the last in popularity. The modern buyer is attracted by the affordable price, ease of operation and reliability of the units. But, like any technique, this one also fails over time, especially if you do not follow the manufacturer's recommendations.

Causes of breakdowns

Indesit invests a lot of time and resources in the production of innovative models with rich functionality. You can find top-loading and bottom-loading washing machines on sale. In most cases, non-observance of the rules for operating the equipment becomes the cause of the breakdown. In the instructions for the washing machine, the manufacturer describes the features of the use of technology.

Most often, the cause of the breakdown is simple blockage of the filter or drain hose. In this case, it becomes impossible to supply water or remove it from the system. Such repairs can be done with your own hands at home, without the involvement of a specialist. It is enough to clear the blockage to eliminate the malfunction.

Other reasons include:

- improper operation;

- lack of timely service;

- negligence on the part of the child;

- the presence of a foreign object inside the machine;

- starting without water.

Diagnostics

The manufacturer took care of the consumer and provided test mode for launching vehicles... This is the easiest way to check if it is working properly or if there is a problem. The error code is displayed on the electronic display. The instruction manual contains a table with full decoding of codes, by which any user can understand what exactly does not work in the system.

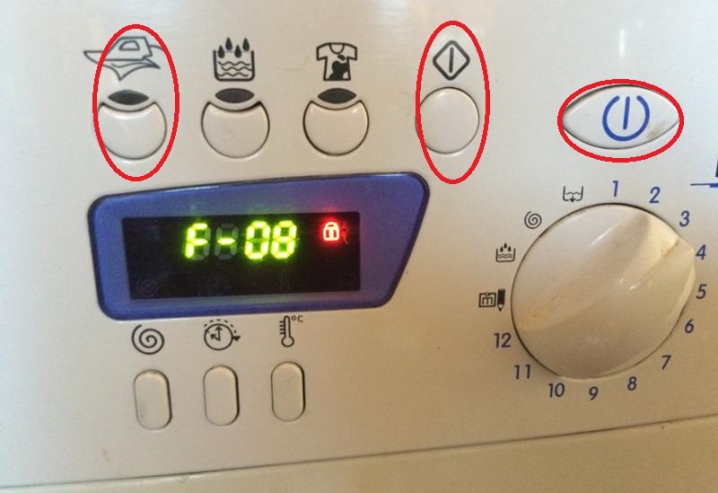

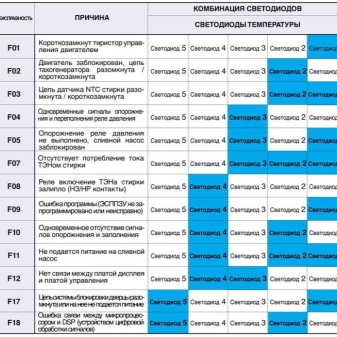

If the model does not have a display, then you should pay attention to a combination of illuminating diodes located on the front panel. Only the top row matters. It is located above four buttons responsible for additional functionality. All possible errors are listed in the table.

To accurately determine the cause of the breakdown - you should first wait until the corresponding code appears on the display. Pre-programmed self-diagnostics allow the technician to pinpoint the problem. For example, if an error occurs with the heating element, then the inscription F07 will be visible on the electronic board. It also happens that the self-diagnostic function is not provided. In this case, you will need to make an external inspection of the equipment.

Determining the cause of the problem in this way is possible only if you have certain knowledge in electronics. If they are not enough, then it is better to consult a specialist.

Almost always, extraneous noise and knocking indicates a breakdown. For example, a hum when a washing machine is running indicates a bearing malfunction. Especially it becomes audible during operation during spinning. When the heating element is broken, the hatch from the equipment remains cold, powder and stains remain on the linen. If there is smoke and an unpleasant smell of plastic, then the problem is much more serious. This is one of those cases when it is mandatory to contact the master.

Preparation

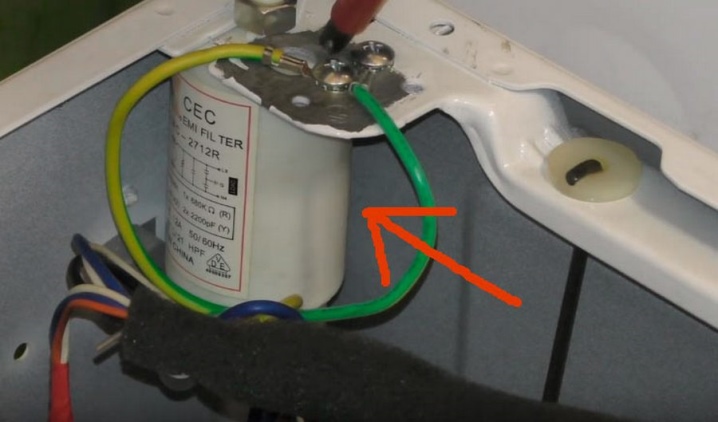

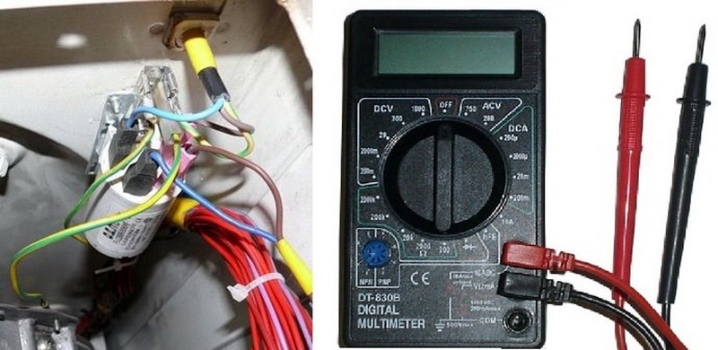

It is worth remembering that it is possible to disassemble the equipment only if its warranty period has expired. Until this moment, the service center is engaged in the service. Self-diagnosis should begin with an inspection of the power filter.It is not difficult to find it in the design of the washing machine, since it is the electrical wire that fits to it.

For work, you will need a tester, which will determine the presence of the power supply. In the absence of electricity on the contacts, it becomes clear that the cause of the breakdown lies in the surge protector. If there is power, then it is worth checking other important nodes. At this stage, it is easy to identify even the most difficult breakdown. Parts and components are best purchased from a specialist store. Analogs are good only when there is no way to purchase an expensive part.

The advantage of the original is that such an element is precisely sized to the type of equipment under consideration, so it will ideally fit in the place allotted to it.

Troubleshooting the main units of the machine

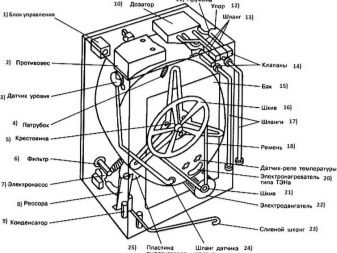

It is worth troubleshooting problems in the main units of technology on your own only if you have enough experience and knowledge in this area. A person who does not know how to properly disassemble and repair a washing machine can turn a small malfunction into a serious breakdown. If you have enough experience, then you can fix it yourself:

- stuffing box;

- motor;

- hatch cuff;

- thermostat;

- tray;

- crosspiece;

- pipe branch;

- capacitor;

- fuse;

- tachogenerator;

- a heating element.

Removing the counterweight is also easy with the right tools at hand. The repair of the processor should be entrusted to a specialist, especially if the washing program constantly gets lost.

Drain pump

Normal operation of equipment is impossible without draining and drawing water. After each cycle, the laundry inside the drum remains dry, and the dirty water is discharged into the sewer system. It is the pump that plays an important role in the described process. Before you start changing this unit, you should make sure that the cause of the breakdown lies in it. By the operation of the automatic machine, you can easily determine when the pump has failed.

Among the main features:

- the corresponding error code appears on the display;

- the wash cycle was incomplete, and the equipment stopped with a tank in which water remained;

- water is inconsistently removed from the machine;

- it is impossible to turn off the pump.

To replace the pump, you will need to remove it. To do this, you need to prepare a set of tools:

- slotted and Phillips screwdrivers;

- pliers;

- for measuring power supply multimeter.

Mandatory when working with a washing machine safety precautions must be followed. The power must be off and the inlet valve closed. The remaining liquid is drained. In parallel, the impeller can be inspected. At the bottom of the front panel there is a small slot where the filter is located. It is unscrewed counterclockwise. Hair and threads on the impeller are removed by hand.

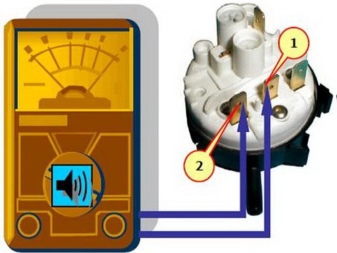

Washing mode switch

If two LEDs start to light on the panel at the same time during the wash cycle or the appliance stops without completing the cycle and drains the water, then there are problems with switching modes. An error code F08 may appear on the electronic display. In this case, we are talking about sticking of the heating element relay. Another reason is the pressure switch, which hangs in the fill mode. To cope with the error, you need to carry out a small diagnosis and examine:

- board, namely contacts to connector J3;

- check the pressure switch with a multimeter;

- the wiring that goes from J3 to the pressure switch.

Most often, replacing a heating element, board or pressure switch can eliminate the breakdown. The heating element can be changed independently without the help of a specialist, since it is easy to access it. To do this, you need to remove the panel at the back. She, in turn, is fastened with several bolts. Experts advise checking the heating element before replacing it. For this, a megohmmeter is used. One end of the probe is hooked to the terminal on it, and the other to its body. If at least some value appears on the device, it means that it is broken.

Drum bearings

Among the disadvantages of the Indesit technique, a small tank can be distinguished. This feature is often the main reason why bearings in such washing machines quickly fail. It is impossible to disassemble the unit on your own, the tank is sealed. Experts advise contact an experienced repairman who will completely replace it.

Such repairs are expensive, sometimes it is better to buy new equipment. Only some Indesit models that are produced in Turkey and Italy do not have this feature. Their tank is not sealed, so it is possible to replace only the bearing.

Tank shock absorbers

If we talk about shock absorbers, they always wear out quickly if the user overloads the washing machine. That is, when the equipment holds 6 kg of laundry, with an increase in this volume, the life of most of the nodes is halved. To get to this element, you will need to remove two panels: the back and the front. If the model does not provide a bottom, then you can get up from there. The shock absorbers are located under the tank. To remove them, you need to unscrew the fasteners. It is worth changing the shock absorbers only in pairs.

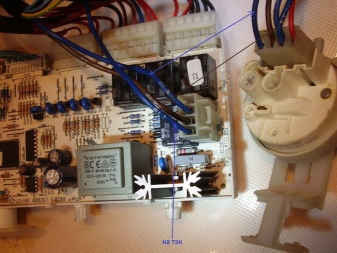

Control module

Indesit is a reliable technology with a quality control module. The manufacturer took care of equipping it with a special protection system. This node is particularly sensitive to moisture and power surges. When a module error appears on the electronic panel, it is necessary to diagnose and pay attention to the following points:

- whether condensation has appeared on the conductive wires;

- whether the contacts are securely fastened;

- if there are traces of oxidation;

- if there is a blockage in the filter or hoses.

The service center, if the warranty is valid, will fix this problem for free, which is why it is not worth opening the seal and doing repairs yourself.

Inlet solenoid valve

The inlet valve works on the same principle as a regular one, through which water is supplied. If it breaks down, you can find out about the malfunction by the following signs:

- a code with a corresponding error appears on the display;

- the tank is filled with water, this process does not stop;

- when the equipment starts working, there is no sound signaling that water is being drawn into the tank.

Before you repair the solenoid valve, you will need see the filter. Here it is presented in the form of a mesh, which is designed to trap small debris, including hair and threads. To get to the valve, you need to remove the top cover of the washing machine - it is held by several screws.

The element may not always show external signs of damage. If they are missing, the part must be removed for a thorough inspection. The hoses leading to the valve will need to be disconnected. Metal clamps can be unclenched with pliers. There may also be a blockage in the valve. It is worth attaching a hose to it above the sink and letting the water in. When the element is in good working order, it is easy to let water through. The presence of a leak indicates the need to replace the valve.

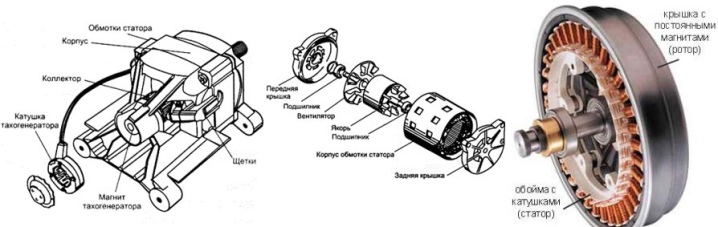

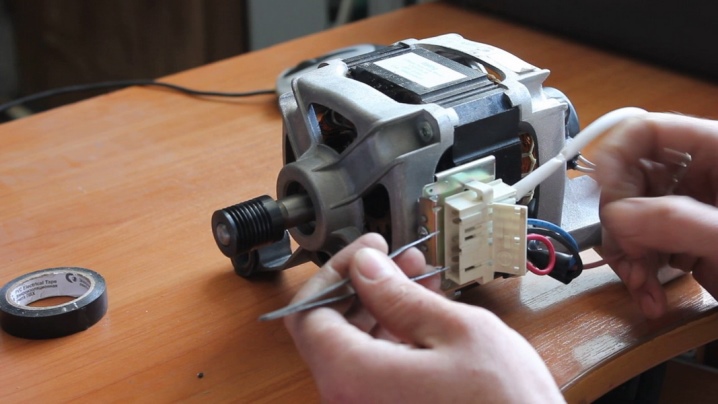

Electric motor

Washing machines Indesit are unpretentious, therefore they are popular. But even with such a technique, the electric motor may fail over time, in which case expensive repairs are required. In any washing machine, the rotation of the drum is provided by an electric motor. Older models used a belt drive, newer ones with direct drive. Regardless of design, any engine is susceptible to failure. Among the main faults:

- brushes worn out;

- breakage of the winding;

- breakage of the collector lamellas.

Usually, brushes wear out when the equipment has been in use for many years. It is possible to determine the breakdown by the sparks from the engine or by their size, since they wear off and, accordingly, become smaller. There are no chips or cracks on a good part. If you purchase a replacement part, it is desirable that it be original. Such parts have an increased margin of safety. You can make repairs with your own hands.

Concerning cliffthen it can occur in the stator or rotor winding. The best solution in this particular case would be a complete replacement of the spare part.... Rewinding a motor is sometimes even more expensive than buying a part. To determine if the lamellae are worn out, you need to inspect the manifold. When burrs appear on their surface, contacts break or detachment is observed, sparks appear.

As a result, the engine overheats. If there is a break in the wires, then it is almost impossible to return them to their place. A closer inspection of the motor may reveal that the armature touches the stator. Experts advise replacing both elements.

Often the user has to deal with a situation where the drum rotates too slowly or does not rotate at all. This is a consequence of a short circuit that occurs between the turns in the winding. The reason could be overheating of the engine housing, which is why the thermostat worked.

The temperature at which the electric motor must operate should not exceed 80 C. To test this assumption, you need to use a tester. It is attached to the lamellas. The resistance should be in the range of 0.1-0.4 ohms. The cause of a short circuit is often a violation of the integrity of the winding.

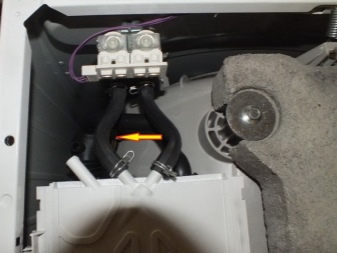

Network filter

When the surge protector fails, it must be replaced. It makes no sense to repair it. However, experts remind that even a new filter may not work for long, even if there were no large voltage surges in the network. The main cause of the malfunction is not a jump, but an accumulation of condensatewhich causes a short circuit. There is a way to extend the life of the described part. To do this, its contacts must be cleaned, and then wiped well with a rag and additionally filled with a silicone-based sealant.

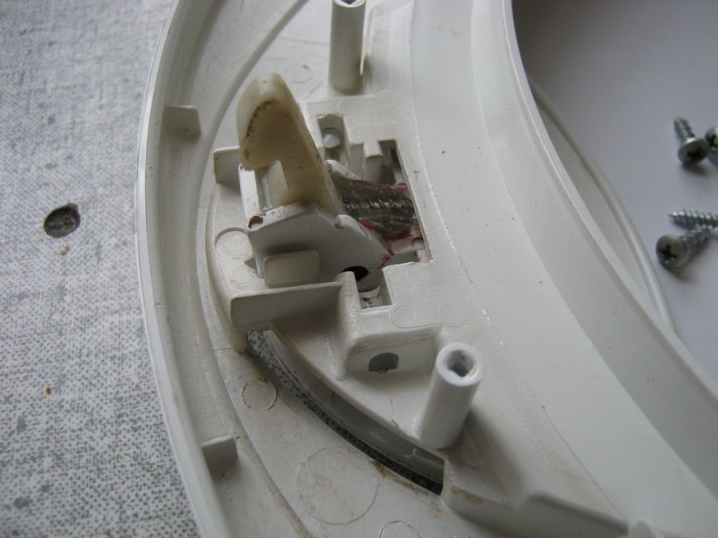

Manhole cover locking device

If the lock of the lock cover breaks, the washing machine simply will not turn on, since the system does not receive a signal about the tightness of the door. The manufacturer similarly thought out the design of the locking device, that there are contacts at its ends. If they are open, then there is no power to the motor. In most cases it is necessary to change the element, but sometimes it is enough to simply clean it. It also happens that the handle is broken. You can repair it on your own, you just need to read the instructions on how to do it correctly. If the blocking does not work, then this may be an error in the control unit.

Helpful hints

It is not always enough to lubricate the contacts with silicone, to clean out the blockage in order to restore the working capacity of the washing machine. The user must listen to what sound the technique is working with. The appearance of a knock and hum indicates a breakdown of the shock absorbers. When there is not enough lubricant, an unpleasant squeak appears as the drum rotates.

Experts warn the user that if the breakdown is associated with shock absorbers or damper, the use of equipment is strictly prohibited. If a person wants to save money, he can simply change the rubber tab that is on the shock absorber. Such repairs do not guarantee that the equipment will work correctly afterwards. Most likely, you will soon have to face the same problem again.

The best way out is to buy a new spare part and preferably an original.

The powder compartment should be cleaned from time to time. Pay particular attention to the pump, which plays an important role in the washing machine system. Of the other nodes, it experiences the most load on itself, therefore it is one of the first to fail.

Experienced craftsmen can detect a breakdown by ear. The pump may hum a lot during operation or not make a sound at all. Before replacing the element, you will need to make sure that the water drain system is free of debris. Not only the filter is subject to inspection, but also the hose, the impeller.If these measures did not help to eliminate the malfunction, then the only way out is to replace the pump.

It also happens that there is no problem as such. The lack of water supply or too little pressure is a consequence of the lack of water in the tap. There may be a problem with the inlet hose or its filter. If the water does not go well, the cause is almost always a blockage.

For information on how to replace bearings on an Indesit washing machine with a glued tub, see the next video.

The comment was sent successfully.