Repair of the control unit of the washing machine Indesit

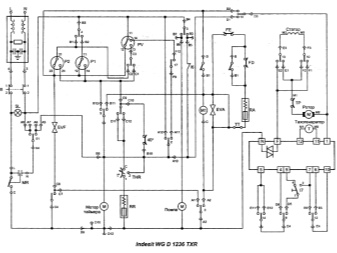

Sometimes it happens that the control unit of the Indesit washing machine fails. In this case, it is not always necessary to call a master, sometimes repairs can be carried out on their own. But it is imperative to use the electronic circuit board of the machine.

How does it work?

A washing machine control unit usually consists of two separate boards. The first carries out the implementation of the management program and is responsible for:

- start of pumps for draining;

- door lock during operation;

- control of the amount of water and its temperature;

- regulation of the speed of the electric motor;

- countdown of the program runtime;

- control of the inlet water pressure and the functioning of the feed shutter;

- automatic shutdown after washing;

- self-diagnosis of the machine.

The second is needed for a convenient interaction between man and machine. It contains buttons, regulators, indication diodes, displays, additional connectors and more. The interaction of these two "cerebral hemispheres" occurs through connecting wires, buses and loops.

How do I identify problems?

More than 45% of malfunctions occur in the “brains” of the washing machine. If you do not take measures, then they can provoke breakdowns of the executive bodies. Here are the most striking signs of malfunctions in the control system.

- Inappropriate "behavior". The machine spins the drum madly, cyclically drains and pours water for no reason.

- Does not turn on. The indicators on the front panel are off, the machine does not show any signs of life at all, and it is definitely plugged into a power outlet.

- Hangs when trying to turn on. On the panel, red indicators are lit, self-test does not stop.

- Doesn't work and writes an error. The display shows an error code and the sectors may not light up.

- Does not wash according to the program. Instead, it produces chaotic actions, instead of 30 minutes, it can wash an hour or two.

- The temperature regime of washing is not observed. The temperature discrepancy can be determined by the indication or thermometer, as well as by feeling the glass door.

- Chaotic blinking of indicators on the panel. The diodes blink or light up all at once, and incomprehensible symbols appear on the display.

- Excessive heating in the area of the engine or heating element. It can be identified by touching the body. But only if there is grounding.

- Inadequate drum rotation. The motor may stall in the middle of a wash or suddenly start spinning in the opposite direction.

Unplug the washing machine immediately if these symptoms appear. If they appear after repeated switching on, then something is wrong. It is necessary to distinguish between malfunctions of the control unit from others. For example, low revs and running noises can be caused by the slipping of the drive belt. The wrong temperature may be due to the relay. Some models have a self-diagnostic function that will inform you about problems. Its action is described in the operating manual, and is usually called by pressing all control buttons at the same time.

How to repair with your own hands?

Before inspection and further repairs, you must:

- disconnect the machine from the network;

- drain all the water from it;

- move the program selector down by disabling them;

- turn off the water heating.

Attention. All actions you perform at your own peril and risk.

We strongly recommend calling the wizard or buying a new module "Arcadia", in any case, do not go into electronics without the appropriate knowledge. First, check the buttons. If they do not always work, then the fault has been found.And make sure all relays and sensors are working properly. Repair should always start with the simplest. During the repair process, you need to determine a number of important provisions.

When it is advisable to replace the board

If the module shows serious damage, carbon deposits or cracks on the board with the naked eye, it is best to replace the control unit. Well, or when the block is in perfect external condition, and the reason is clearly in it.

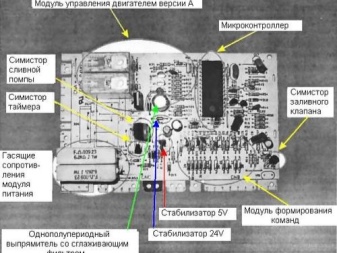

Location

The unit is located just behind the front panel, which is marked with selector positions and indicator designations. The panel must be removed to access the board.

Dismantling

Remove the front panel first, usually it is secured with countersunk screws or latches. Next, take a picture of the location of all the wires and only then dismantle the boards. Just be careful, they are fragile.

Component check

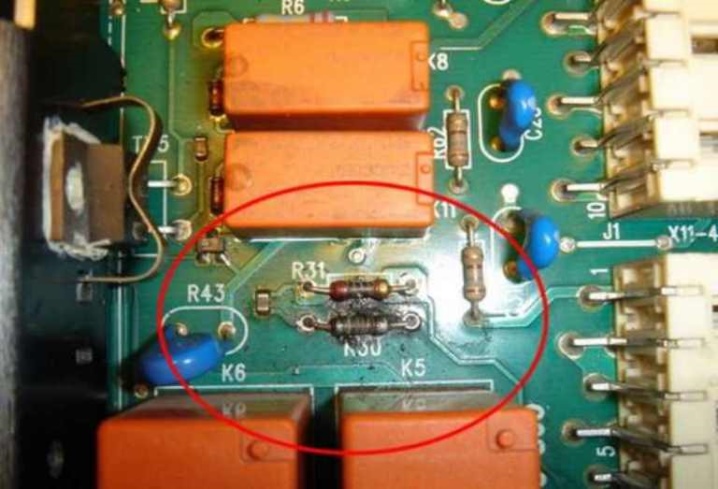

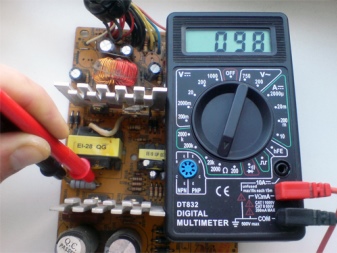

Examine the boards. Wipe them with alcohol if necessary. If they are in perfect external condition, it is better to consult a specialist. If there are burned out elements, then they need to be disconnected and new ones soldered. Examine the contacts carefully. It is possible that the reason is precisely in them. They often oxidize in humid environments and stop working properly.

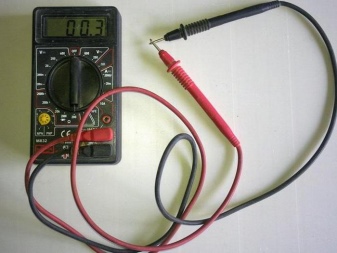

Black or green colors indicate the presence of oxides. They should be cleaned off with a moderately sharp object such as a screwdriver or the dull side of a knife. For fine cleaning, use a cotton swab dipped in alcohol. Only alcohol should not be too much. If the contacts are clean, then it's up to the elements of the board. To check them, a multimeter or a capacitor tester will definitely come in handy. You can do with an ordinary ohmmeter, but not everything can be checked.

Repair of the control unit "Arcadia"

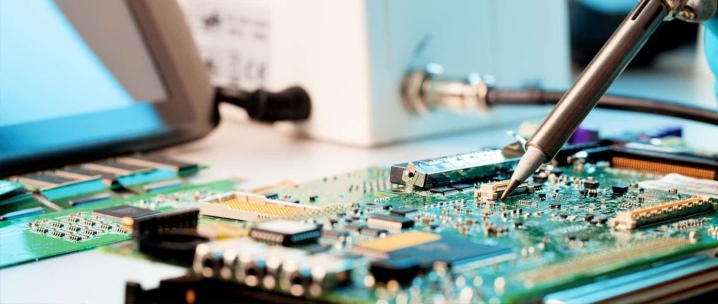

Replacement of elements on the control board is carried out with a thin-tip soldering iron or using a soldering station. In any case, work carefully, do not overheat parts (especially semiconductor ones) and follow safety precautions.

After repairs, check that the tracks are not accidentally closed with solder.

If so, it must be carefully peeled off with a sharp object (the solder is soft, a knife or scalpel is suitable for the work). Then wipe the area with rubbing alcohol and, if possible, cover with insulating varnish.

Capacitors

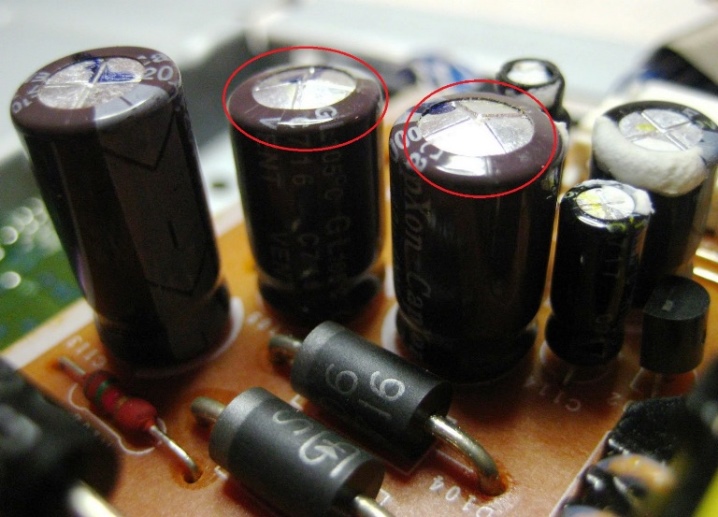

Worn out capacitors inflate. If there are any, feel free to change. When they are outwardly working, use an ohmmeter to check them for a short circuit. It is advisable to use a device to check the capacity, but then the capacitors will have to be soldered and re-soldered. If the resistance is zero, the part is defective.

But first wire the leads for guaranteed discharge. By the way, capacitors most often fail.

Be sure to observe the polarity during installation.

And it is better to take a high-quality photo of the board before repairing - to prevent problems in the future.

Resistors

For testing, they usually do not need to be soldered. Measure the resistance with a tester or ohmmeter. Then compare it with the declared one, which can be identified by the color coding of the resistor. If it does not match, the resistor must be replaced. It has no polarity.

Thyristor block

They have a variety - triacs. They are not fundamentally different. To check, you need to do the following.

- Set the resistance measurement limit on the multimeter to 2 kΩ for the highest voltage across the probes.

- Connect the probes to the cathode and anode of the thyristor, observing the polarity (cathode - minus). The resistance must be endless.

- Connect a jumper between the anode and the control electrode. Resistance should drop sharply.

- Remove the jumper. If the resistance tends to infinity again, the thyristor is serviceable.

Checking trigger status

To do this, you need to measure the voltage between the input contacts. If it is less than 12 V, then the device is usually working properly. For reliability, measure the resistance of the trigger filter. It should be 20 ohms.

Thus, a simple repair of the washing machine can be done by yourself. This requires simple instruments, skillful hands and self-confidence.If in doubt, watch this video.

Class, thanks, very helpful! I wish you good luck and prosperity!

The comment was sent successfully.