Bearings for the Indesit washing machine: which ones cost and how to replace?

One of the important components in the mechanism of an automatic washing machine is the bearing device. The bearing is located in the drum, it acts as a support for the rotating shaft. During washing, as well as during spinning, the bearing mechanism works with significant loads, withstanding the weight of the laundry and water. Regular overloading of the washing machine can damage the bearing. If it wears out, the washing machine begins to hum and vibrations increase during the spin program. It is worth noting that the spin quality is also beginning to deteriorate.

In order not to wait for a serious breakdown, it is necessary to diagnose and repair the bearing mechanism at the first signs of malfunctions.

What are they worth?

Many options for inexpensive Indesit washing machines, for example, the WISL 105 X, WISL 85, IWSD 5085 brands and others, have a one-piece non-separable tank in their design. This circumstance significantly complicates the process of replacing the bearing mechanism. It is much easier to get close to it in models with a collapsible tank.

Owners of washing machines with solid tanks are often offered a complete tank replacement instead of repairing the bearing mechanism, but this radical step is not necessary. It is best to entrust the repair of a one-piece tank to the specialists of the service center, who, after replacing the bearing, perform the gluing of the tank. As for a machine with a collapsible tank, you can try to replace the bearing on your own. Before starting work, it is worth choosing the right bearing for the Indesit washing machine. Different machine models have specific bearing serial numbers in their design:

- 6202-6203 series numbers are suitable for WIUN, WISL 104, W 43T EX, W 63 T models;

- 6203-6204 series numbers are suitable for W 104 T EX, WD 104 TEX, WD 105 TX EX, W 43 T EX, W 63 T, WE 8 X EX and others.

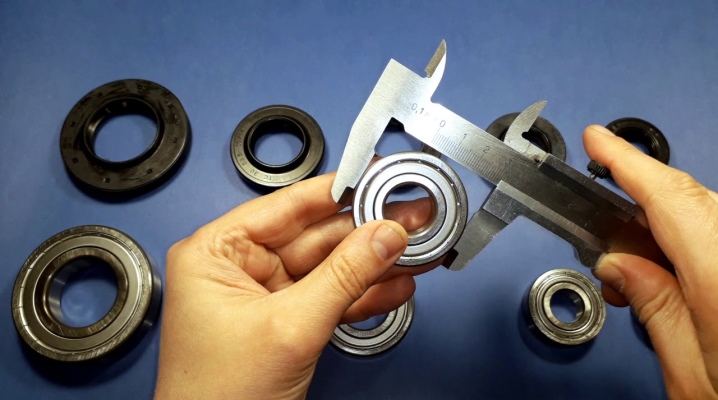

Bearings are also selected based on the volume of the machine's tank - for 3.5 or 5 kg of linen. In addition, oil seals will be needed for repairs, they are 22x40x10 mm, 30x52x10 mm or 25x47x10 mm. Modern washing machines have plastic or metal bearings. Most often, models made of metal are used, but plastic ones are considered reliable, since they are equipped with a protective dust cover.

According to home appliance masters, machines with plastic bearing mechanisms last a little longer than their metal counterparts. Moreover, models with plastic bearings are slightly more expensive than machines with a metal mechanism. In order to perform a quality repair of a washing machine drum bearing, it is important to use original spare parts that are suitable for Indesit models. 1 or 2 bearings are subject to replacement, as well as an oil seal.

It is necessary to change all these elements at the same time.

When should you change?

The average service life of the bearing mechanism in automatic washing machines is designed for 5-6 years, but if the washing machine is used with care and does not overload it in excess of the established norm, then this mechanism can last much longer. You can understand that it is time to replace the bearing mechanism by paying attention to the following signs:

- during the spinning process, a knock appeared at the washing machine, reminiscent of a mechanical hum, and sometimes it was accompanied by a grinding noise;

- after washing, small water leaks appear on the floor under the machine;

- if you try to rotate the drum in any direction with your hands, you can feel that there is a slight backlash;

- during the washing process in the washing machine, extraneous mechanical sounds are heard.

In the event that you find one of these signs or they are present in the general set, you will need to diagnose and replace the bearing mechanism. You should not ignore these symptoms of problems, as they can lead to more serious problems, the elimination of which can be much more expensive in terms of repair costs.

How to remove?

Before removing the bearing, you will need to disassemble some parts of the washing machine. This work is voluminous, it is best to do it with an assistant. The procedure for disassembling the Indesit washing machine is as follows.

- Unscrew the screws on the top cover and remove it. They do the same with the back cover of the case.

- Next, unscrew the fasteners of the upper counterweight and remove it.

- Take out the powder tray and unscrew its internal holder, and at the same time unscrew the fasteners of the filler valve connected to the holder of the powder tray and the back of the housing. Disconnect the valve connectors - there are two of them.

- Detach the control panel, move it aside.

- Disconnect the branch pipe attached to the tank and the water level sensor, in parallel remove the tap water supply hose from it.

- Remove the drive belt from the pulley, which looks like a large wheel. Detach the connectors of the temperature relay, disconnect the wires from the heating element and remove it together with the relay.

- Disconnect the electrical wires from the engine, after which the washing machine must be placed on its side.

- Unscrew the nuts securing the shock absorbers and remove the clamp with pliers that holds the drain pump pipe. Then remove the rubber seal.

- The washing machine is returned to the upright position. Remove the clamp holding the rubber sealing ring near the hatch door, and remove the edges of the rubber inside.

- The tank is removed by grasping the springs and pulling them out of the mounting slots. Movements are made in an upward direction. It is better to do this together with an assistant.

- The lower counterweight is removed from the tank and the engine is disconnected. Then you need to gently hit with a hammer on the pulley screw, but it is better to do this through a brass or copper die, then unscrew the screw, dismantle the pulley and remove the pipe.

After carrying out these preparatory work, access to the bearing mechanism appears. Now you can start replacing it.

How to replace?

To replace the bearing, you must first remove it. For this use a special tool called a puller. If it is not there, you can do otherwise: with the help of a chisel and a hammer, the old bearing must be knocked out. Next, remove dirt and old oil grease, treat the surface of the shaft with fine sandpaper. Then new bearings are installed.

The operation is performed using a puller or carefully hammer them into the seats with a hammer and guides (these may be old bearings). The procedure must be carried out accurately and accurately, without damaging the inside of the mechanism. Then a suitable oil seal is installed, and inside the mechanism, lubrication is processed, for example, lithol can be used for this. After installing the bearing, reassemble in the reverse order and test the operation of the washing machine.

For an illustration of how to replace the bearing, see below.

The comment was sent successfully.