Candy washing machine error codes: description, reasons, problem solution

Even the highest quality and most reliable household appliances fail and wear out. Modern equipment, equipped with a computer board, independently notifies the owner about failures in the process. A special coding is used to indicate malfunctions.

Description of errors

Each Candy washing machine code indicates a specific problem. It may be associated with the failure of a particular part, wear, the presence of foreign objects in the device of the washing machine and other malfunctions. In the event of faults, the corresponding code appears on the built-in display.

Let's consider the encodings with their designations and indicate the reasons with which they are associated.

- E01. The problem is related to the hatch (door) of the washing unit.

- E02. Problems in the water intake system.

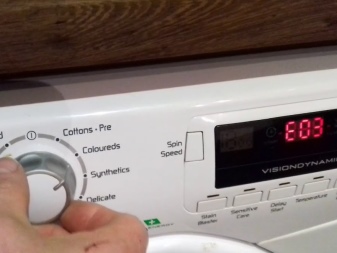

- E03. Malfunctions when draining waste water.

- E04. The filling valve does not perform the assigned functions.

- E05. The sensor responsible for the temperature is out of order. And also this code indicates a possible malfunction of the heating element, controller or motor of the program selector.

- E06. Problems with the washing machine control module.

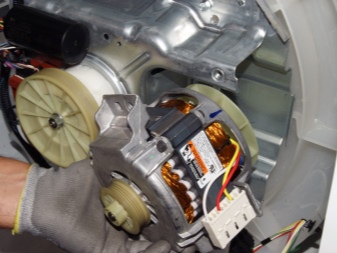

- E07. Tachogenerator malfunction.

- E08 (or E17). If this symbol appears on the screen, the cause of the failure is in the engine control system or tachogenerator.

- E09. Malfunction of the triac or unit control unit.

- E14. A very rare mistake, which is confirmed by the specialists of the service centers. This code can be seen on top-load models equipped with displays. The error indicates a defective heating element or a problem with the contacts.

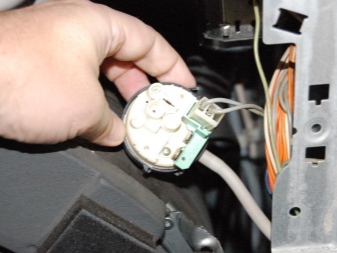

- E20. Incorrect operation of the sensor responsible for the water level in the tank.

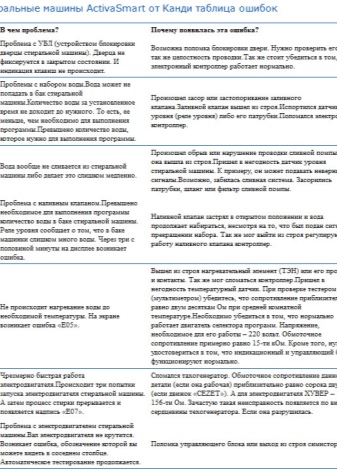

Recognizing errors without a screen

Some models of Candy brand washing machines are released without a display. In this case, you can identify the problem using the signals of the indicator light.

The user needs to count the number of flashes. There is a 5 second interval between flashes, so you have to be patient.

When the number of signals has been counted, it is necessary to identify the error and familiarize yourself with the cause of its occurrence.

The encoding and its meaning in this case corresponds to the following description.

- 0 - Incorrect operation of the unit control module.

- 1 - The door of the washing machine does not lock properly. There may be problems with blocking the hatch.

- 2 - Water does not flow into the tank: insufficient head or head velocity. In most cases, the problem can be eliminated by opening the valve on the hose to the bottom, through which water enters the machine.

- 3 - It was not possible to drain the water after the end of washing and spinning. The pump is responsible for this process, so you need to check it first.

- 4 - Excessive volume of liquid in the tank. Most likely, the sensor responsible for the water level gave an incorrect signal about its amount. And also the problem may be a malfunction of the contacts. Do not forget about the filler valve, which can jam during operation.

- 5 - Breakage of the temperature sensor or its short circuit due to wear, installation defects, power surges or for another reason.

- 6 - Error in memory operation (EEPROM - programmed NMC). The control unit is responsible for this element.

- 7 - Problem with the engine. The most common reason is that it is simply jammed.

- 8 - Incorrect functioning of the tachogenerator.

- 9 - Incorrect operation of the triac.

- 12.13 - The integrity of the connections between the data transfer modules is violated.

- 14 - Malfunction of the control unit.

- 15 - Software error.

- 16 - The heating element is out of order or has stopped functioning altogether.

- 17 - The tachogenerator gives out incorrect work data.

- 18. Problems with the power supply. Control unit malfunctions.

additional information

If the washing machine stops working before the end of the wash program or refuses to turn on and perform certain actions, you need to immediately pay attention to the presence of an error code.

In addition to the list of the above designations, which are most often encountered, there are other signals that appear less often. In some cases, the display shows words or certain characters. For example, the following.

- Snowflake image. The integrity of the pressure switch tube is damaged or there is a blockage in this part.

- PROG. CONTINUE. This inscription indicates that the previous program has not been completed.

Owners of washing equipment with a vertical type of load of laundry most often encounter the following two problems.

- E14. The contacts leading to the heating element of the machine have oxidized.

- E16. The heating element has burnt out, without which the operation of the washing machine is impossible.

The models belonging to the Aquamatic series have 3 error codes.

- The machine's hatch is jammed or blocked. The controller is not working properly.

- The tank is not filled with water.

- Problems when draining the waste fluid. This may be due to clogging or equipment failure.

Causes

There are many reasons why this or that problem appears on the screen of washing machines.

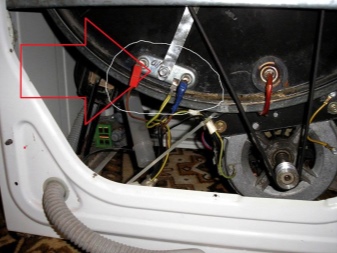

- E01. The electronic controller is out of order. The integrity of the wiring or contacts is broken. The mechanism responsible for blocking the hatch during operation of the equipment broke down.

- E02. The fluid intake valve has become unusable. The hose through which the waste water is drained is clogged. The pressure switch has stopped working properly. Electronic controller malfunctions.

- E03. The water drainage path is clogged. Damaged wiring or drain drift out of order. Problems with the pressure switch.

- E04. Improper functioning of the valve responsible for water intake. Defective controller or filling valve.

- E05. Temperature sensor error. Wear or breakdown of the heating element. And also this error can be associated with a breakdown of the motor and controller. This code appears on the display due to a malfunction of the programmer.

- E06. The module refuses to work properly. Possible memory errors in the washing unit.

- E07. The core of the tachogenerator has broken, or this element has completely stopped performing the assigned functions.

- E08 (or E17). Motor blockage or partial stop. The monitoring module is not working properly. Perhaps one of its elements burned out.

- E09. The drive motor shaft of the washing machine has stopped. The control unit of the technique or the triac is broken.

- E14. In most cases, the cause of the error is that the heating element has burned out. In addition, the contacts could oxidize, due to which their work was disrupted. It is recommended to pay attention to the integrity and serviceability of the electronic board.

Trouble-shooting

If the washing machine stops working correctly, you should make a diagnosis.

Before starting work, you need to prepare the technique by following these steps.

- Remove all things from the tank. If necessary, it must be freed from water.

- Close the hatch tightly.

- Make sure that the "Drum balancing" mode is disabled.

- Turn off equipment and disconnect power.

The automatic testing mode is carried out according to a specific algorithm.

- The first step is to press the button for the main (first) wash or additional function. This key is on the left.

- Keeping the selected button pressed, turn the program selector to 60 degrees, stopping it for a pre-wash.

- Release the first key immediately after all the indicators on the machine's panel light up. If done correctly, this will take 5 seconds.

- Click the "Start" button.

Note: If the program fails to start, try again by changing the first key.

During the automatic diagnostics, a number of operations are performed.

- The washing machine draws 6 liters of water. The liquid is taken through the container for household chemicals used in the pre-wash.

- The heating element starts and operates for 20 seconds. There is a pause of one second before starting.

- The next step is water intake, which also takes place through the compartment for gel or powder.

- The machine starts the drum at a maximum speed of 55 rpm. It spins counterclockwise for 16 seconds.

- The technique then stops for 4 seconds.

- A set of liquid and a new start of the drum at the previous speed.

- After 16 seconds, the drain pump starts working.

- The final stage is spinning for 15 seconds.

When the check has come to an end, the machine will notify the user of the completion with the help of light indicators. They will light up at the same time.

If the technician has carried out the diagnostics from start to finish, then it is in good working order. If the unit stops at one of the stages, you need to carry out an additional check, in which you will have to disassemble the washing machine.

Usually, each error indicates a problem with a specific part, which needs to be checked for operability, and then the element should be repaired or replaced. Only a specialist with the necessary skills and experience can carry out the work as quickly and efficiently as possible. Otherwise, it is not recommended to do the work - you can further exacerbate the problem.

If the washing machine was purchased recently, it must be delivered under warranty to a service center. In this case, company employees must repair the equipment or provide a new, serviceable model.

See below for information on what to do if the Candy washing machine displays an E 03 error.

The comment was sent successfully.