All about pallet racking

Pallet racks are structures that allow you to store products, goods and any items that need to be stored indoors. They can be assembled and disassembled as needed.

Such designs allow you to organize and optimize the space when placing goods located on pallets.

Advantages and disadvantages

Among the obvious advantages of pallet racks are the main ones.

- Wide scope of use. The design is ideal for a retail or wholesale warehouse, industrial plants, private areas, factories, factories and workshops.

- Varieties of shelving. Their number allows each client to choose the option that suits him. The parameters are selected depending on the area of the room, the load that the pallets must withstand, and the amount of cargo to be placed.

- Ease of use. The enterprise can organize both manual work and the use of equipment that interacts with loads. Pallet racks allow you to fully optimize the space and fill all the shelves. At the same time, products can be placed at different levels: this allows you to comply with storage conditions, based on the specific characteristics of the product. What's more, pallets make inventory easier.

There are also disadvantages to using this type of construction.

- Pallet racks allow you to properly organize the space if the main goal is to place goods in the warehouse. If at the same time you need a large work space, then it is worth noting that pallets can take up to half of the area of the room.

- Some racks are difficult to assemble. Moreover, complex structures sometimes require maintenance costs.

Basic structural elements

Pallet racks have become one of the most popular ways to store goods, and their simple design is one of the reasons for their widespread use. In most cases, the rack consists of certain elements.

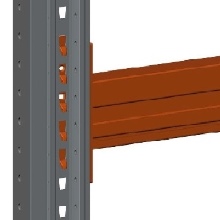

- Frame, which consists of a pair of uprights, bolted together. In the lower part, thrust bearings are attached to the posts. Frames are made of different heights and depths: these parameters are selected depending on the dimensions of the products that will be stored in the warehouse of the organization.

- The stand is made of steel. Its width and metal thickness depend on the load capacity required by the rack section.

- Vertical profile - an element that transmits the force of the structure through the thrust bearing. Its size, type of steel and thickness create additional pressure that ensures the required distribution at the marked point. To smooth out unevenness in the floor, metal plates are used.

- Beams that are attached to the frames with hooks. At the level of the structure, a load of no more than 4200 kilograms is relied, but regardless of the carrying capacity, bends appear on the beams under load. If you increase the height of the vertical profile, the bends of the beams become smaller.

Description of species

Each warehouse has characteristics and objectives that it must meet. These aspects are important when choosing the type of pallet racking. There are different types of construction, but the most common ones are described below. Among them, everyone will find something for themselves.

Frontal

This type of rack is used much more often than others. The design of this type belongs to the collapsible type, the elements of which are held by bolts or special clips. The basis is made up of vertical frames and beams, which are fixed to the uprights with hooks. The number of tiers of the front rack is selected in accordance with the preferences of the client. Prefabricated pallets can be quickly disassembled and supplemented as needed: for example, they can be completed both in height and in width.

The front rack can stand alone or against a wall. If it is located separately, it will be possible to load it from both sides, which is convenient in cases where products need to be placed quickly. Most often, individual structures are arranged in pairs to save room space. It is necessary to leave free space between the racks so that there is enough space for the work of employees or special equipment.

It is worth noting that technical means are often used for pallet storage, and not manual work.

This design allows you to get constant access to a wide range of products. Such a rack can be installed in almost any room. The paintwork is characterized by quality, thanks to which the front shelves can be kept in a room with a low temperature: for example, in a refrigerator.

The design of this type can be adapted to specific requirements. Thus, you can double or triple the size of the product by doubling one rack with another. The capacity of the structure increases, but it will not be possible to quickly handle the load. Moreover, to fill the rack, you will need to use special equipment.

Depth rammed

Depth racks, also called rammed racks, are an excellent replacement for enlarged front racks. Their main positive feature is a high level of optimization of the storage space. The rammed structure consists of metal frames connected by horizontal beams with cradles. Pallets are installed on them for storing products. The deep shelving is more compact, it saves a wide aisle working space.

Nevertheless, when using this type, as a rule, the same type of product is placed, which has a long shelf life and does not require sorting.

Mezzanine

The mezzanine is a mobile and multi-level structure that is quickly assembled. It consists of additional levels that allow efficient use of space. This is the main advantage of mezzanine racks - you can use the entire height of the warehouse. There are different types of mezzanines. The first is a pallet mezzanine, which is based on a frontal view system. As a rule, it should be installed if it is supposed to use special equipment when performing cargo work. The second is a shelf, and such a structure should be assembled by those who plan to use manual labor in the process.

It should be noted that regardless of which type of rack is suitable for a particular organization, it is always necessary to focus on the weight that will exert a load on the product. For heavy loads, it is better to use reinforced structures.

It is necessary to mention such a category of storage facilities as self-supporting racks. They are quickly erected and are a collection of interconnected pallet structures. This is a single monolithic system, which is a part of the building in which it is located. It is stable and capable of carrying heavy loads.

Selection Tips

In most cases, the success of all its work depends on how the enterprise's warehouse is organized. Therefore, it is worth choosing pallet racks correctly. In order not to be mistaken with the choice, pay attention to important aspects.

- For pallets, capacity is important, so you should choose the right rack dimensions. In addition to products that will be permanently stored in the warehouse, the rack must be able to accommodate additional cargo.

- Be sure to take into account the load that the products in the warehouse will have on the rack.

- If the free working space is of great importance, it is necessary to be guided by such a parameter as the width of the pallet rack. In this case, it is better to choose a design that does not take up much space in the room. For this, a multi-tier type of rack is suitable, which is compact.

- Prices for pallet racks are kept within reach, but when choosing, you should focus more on the quality and rationality of the purchase than on its cost.

- It is better if the elements are fastened using hooks or bolts.

- If the racks and shelves are galvanized, they will make the product more practical.

- Internal changes to the rack configuration can be very useful during operation, so it is worth paying attention to designs that provide this possibility.

Installation features

It is better to decide on the type of rack and its characteristics at the stage when the design of the warehouse is only planned. It is worthwhile to clearly understand what products will be stored in the warehouse and understand its specifics: how long the goods will be stored, in what conditions, automated or manual work will be used indoors. It may be necessary to combine different types of shelving structures for convenience.

The installation of pallet racks should be carried out by professionals who will competently carry out all stages of installation and will not make annoying mistakes. In this case, the system will be safe and will serve for a long time and with high quality.

The rack must be assembled following the mandatory steps.

- The floor of the room is prepared for work.

- The structure is marked on the floor. It is done in accordance with a project that is prepared in advance. The distance that the rack will occupy is marked.

- Installation of racks and rack ribs is in progress.

- Install and secure the frame of the structure. Bolts or special clips are used to fix them.

- Install the beams at the bottom of the rack.

- They fix the beams of other levels of the structure. Installation is carried out from the lower elements to the upper ones.

- All elements are aligned using special devices.

- Install shelves and flooring, fix supporting parts to the floor.

- If desired or necessary, additional structural elements are installed.

It is important to note that welding does not need to be used when assembling pallet racks. All actions are carried out using bolts or special clips. This means that at any time the structure can be disassembled, transported to another place and assembled back. The decks of the structure must also be replaced. They can be exchanged at any time for specialized floorings, which are selected in connection with the characteristics of the product, or simply for new ones.

The comment was sent successfully.