Planing machines

Metal planing is a process in which excess layer is removed from any flat metal surfaces during their processing. It is almost impossible to carry out such work manually, so it is advisable to use special equipment. It is in this category that planing machines belong. They differ in type, technical and other characteristics.

Characteristic

The first device for this purpose was developed more than two centuries ago. In appearance, it was significantly different from most modern models. At the same time, its functionality consisted only in the processing of wooden surfaces. It can be said that in order to obtain such equipment, a conventional lathe was modified and improved. A significant drawback of the old models was the manual movement of the workpiece, that is, the foreman had to bring the machine into working condition by pulling a regular rope. It is clear that in this case the quality of processing decreased. And such activities took quite a lot of time.

It is convenient to process short surfaces on longitudinal planing equipment. All equipment included in this category differs in the following parameters:

- the type of drive in the device: hydraulic and crank-rocker;

- the number of surfaces intended for work: four-sided, two-sided and one-sided;

- drive power: equipment for home and professional use;

- travel configurations table and cutting tool.

All machines of this type are marked with a five-digit number.

- The first of them determines the relationship of the machine to a certain type.

- The second indicates one of two types of equipment: a single-column or two-column machine.

- The remaining numbers provide information on the technological characteristics of the device.

Appointment

As already indicated above, such equipment is designed to remove the upper layers of metal from the surface to be treated. It is noteworthy that when processing medium-sized parts, they can be installed directly on the work surface and processed at the same time. This is the main purpose of such equipment. As an additional function, you can designate surface finishing as well as grooving and grooving.

Of course, such machines are rarely purchased for home use. But if a person is engaged in car repair or deals with metalworking, then this type of planing equipment will be irreplaceable. Most often, planing machines can be found in the shops of various industries in the automotive industry.

Principle of operation

To better understand the principle of the planer equipment, it is recommended that you familiarize yourself with the main components of the machine. These include:

- bed (metal base of the device);

- Desktop;

- engines of different functionality;

- rollers;

- knife shaft.

The direct participant in the process is always a moving work table, on which the workpieces are fixed and processed. The entire working surface of the machine can be divided into two opposite parts: fixed and movable. The conventional separator between them is the knife shaft, with the help of which the surface is processed.The rollers serve as a supporting element and are active when the part moves with the table during machining. Any modern model is equipped with additional accessories that are responsible for safety.

The principle of operation of planers may vary slightly depending on the model, but the general essence remains the same. In order to process the surface, the product is fixed on the work table. The swing arm mechanism performs cyclical reciprocating movements. Conventionally stationary cutters process the material.

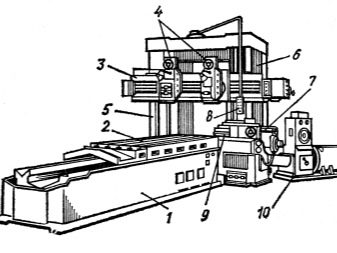

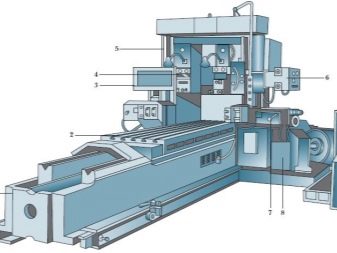

An electrical diagram of one of the longitudinal-transverse machines is shown in Figure No. 1.

The lineup

Planing machines differ in their purpose. There are those that are intended for semi-professional use. There are large-sized models that will be very problematic to purchase and install in a garage or in a small production facility.

If we talk about the first category, then the assortment here is quite rich, and the pricing policy is very different. The most popular model can be considered a planer from the Elmedia Group company. This Russian-made device is more suitable for semi-professional use., for example, to those businessmen who own a private car service. The machine is clearly shown in Figure 2.

Even with a visual inspection, one can conclude about the modernity, compactness and convenience of this model. The advantages of this equipment are:

- low cost (within $ 600);

- small size;

- attractive appearance;

- convenience of work;

- fully automated system.

Of the shortcomings, the most significant is the impossibility of processing large-sized parts. But if we consider that the machine is purchased for amateur use, then this drawback can be considered insignificant.

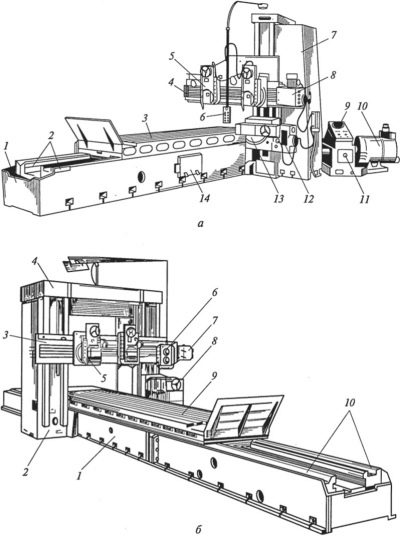

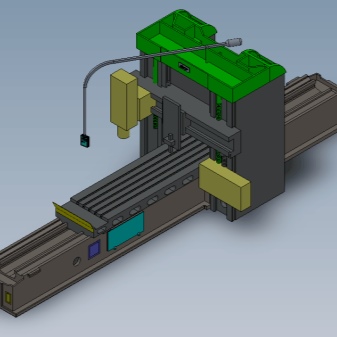

Four-side planer brand WoodTec 418 is also small-sized, but more suitable for use in serious production of various types. This is evidenced by the cost of the device - about 15 thousand dollars. The machine has good technical characteristics, high power and small dimensions. The object is clearly shown in Figure 3.

Jainn Jong FE-423 - a high-speed four-sided machine with a cost of about 43 thousand dollars (shown in Figure No. 4). Belongs to the category of modern equipment. The main advantage is the high processing speed. Its disadvantage, of course, is the high cost. But if production is established, then the price for a large enterprise will not seem so critical.

This is not the entire lineup, but only representatives from each price category.

To buy a quality machine, it is recommended to pay attention to the manufacturer, the availability of reliable safety elements, the impeccable appearance of the equipment and the operating power.

The comment was sent successfully.